In the sand and gravel aggregate industry, the 200t/h aggregate crushing production line is the preferred configuration for medium to large stone processing plants, which can meet the high-standard aggregate requirements in the fields of highways, building concrete, railway ballast, etc. This article will introduce the core equipment, process flow, technical advantages and investment returns of the production line in detail to help you choose the best crushing solution.

Core configuration of 200t/h aggregate crushing production line

1. Coarse crushing stage: jaw crusher (PE-750×1060)

Processing capacity: 200-250t/h

Feed particle size: ≤630mm

Discharge particle size: ≤150mm

Features: high crushing ratio, wear-resistant jaw plate, suitable for high hardness materials such as granite and basalt.

2. Medium and fine crushing stage: cone crusher (HPT300) or multi-cylinder hydraulic cone crusher

Processing capacity: 180-220t/h

Discharge particle size: ≤50mm (adjustable)

Features: laminated crushing principle, excellent finished product particle shape, suitable for secondary crushing of high-hardness rocks.

3. Sand making and shaping stage (optional): impact sand making machine (VSI6X1140)

Processing capacity: 120-180t/h

Discharge particle size: 0-5mm (machine-made sand)

Features: "Stone-on-stone" crushing mode, sand particles are cubic, with reasonable grading, in line with the standards for construction sand.

4. Auxiliary equipment

Vibrating feeder (ZSW490×110) - uniform feeding, prevent blockage

Circular vibrating screen (3YK2460) - efficient screening, accurate grading

Belt conveyor - automated material transportation

Dust removal and noise reduction system - meets environmental protection requirements

200t/h aggregate crushing production line process flow

1. Feeding: The vibrating feeder evenly conveys the raw materials to the jaw crusher.

2. Coarse crushing: The jaw crusher crushes the large stones to ≤150mm.

3. Medium and fine crushing: The cone crusher further crushes to ≤50mm to improve the yield.

4. Screening: The circular vibrating screen divides the aggregate into specifications such as 0-5mm (sand), 5-10mm, 10-20mm, and 20-31.5mm.

5. Sand making (optional): Part of the material enters the sand making machine to produce high-quality machine-made sand.

6. Finished product transportation: Qualified aggregates are transported to the stockpiling area through a belt conveyor, and unqualified materials are returned for crushing.

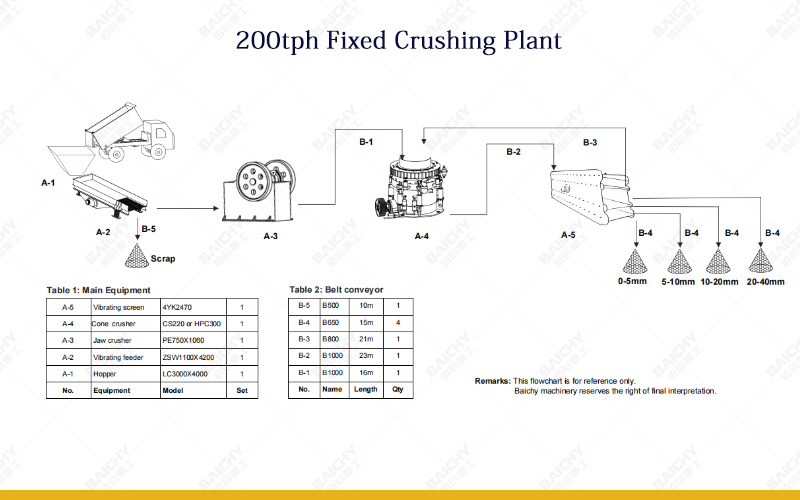

Flowchart example:

Advantages of 200t/h aggregate crushing production line

✔ High capacity and stable operation: 200 tons per hour, meeting the needs of large sand and gravel plants, continuous operation without pressure.

✔ Energy saving and environmental protection: equipped with pulse dust collector and soundproof cover, dust ≤20mg/m³, noise ≤75dB.

✔ Intelligent control: PLC automation system, real-time monitoring of equipment operation status, reducing labor costs.

✔ Strong adaptability: can crush granite, basalt, limestone, river pebbles and other materials.

✔ Fast return on investment: calculated according to the market price of sand and gravel, the cost can be recovered in 1-2 years.

Application case: Granite aggregate processing project

• Raw materials: granite, compressive strength ≥ 150MPa

• Production line configuration: PE-750×1060 jaw crusher + HPT300 cone crusher + VSI6X1140 sand making machine

Product specifications:

• 0-5mm (mechanical sand, accounting for 30%)

• 5-10mm (accounting for 25%)

• 10-20mm (accounting for 25%)

• 20-31.5mm (accounting for 20%)

• Operation effect: average daily output of 4,800 tons, excellent finished product particle shape, used for commercial mixing station supply.

How to choose a 200t/h aggregate crushing production line?

• Select equipment according to the hardness of the raw material: high-hardness rock (such as granite) is recommended to use "jaw crusher + cone crusher", medium hardness (such as limestone) can use "jaw crusher + impact crusher".

• Consider the demand for finished products: if you need mechanical sand, you need to add a sand making machine; if you only need to crush stone, you can omit the sand making link.

• Environmental protection requirements: Choose manufacturers equipped with dust removal and noise reduction systems to ensure that environmental impact assessments meet standards.

• Manufacturer service: Investigate the equipment warranty period and after-sales response speed, and give priority to suppliers that provide free solution design.

The 200t/h aggregate crushing production line is an efficient production solution for the sand and gravel industry. Reasonable configuration can greatly improve production capacity and finished product quality. Baichy Heavy Industry provides free production line design, equipment quotation and installation guidance. If you are planning an aggregate crushing project, please consult online or call 0086 15093222637 to get cated solution!