With the continuous development of infrastructure construction, sand and gravel aggregates, as indispensable raw materials, have a huge market demand. Limestone, due to its moderate hardness and abundant resources, has become the preferred raw material for producing manufactured sand and aggregates.

A scientifically designed and stably operating limestone crushing production line with an hourly output of 100-150 tons is key to achieving high efficiency and profitability for medium to large-sized sand and gravel plants.

This article will provide a comprehensive analysis of how to configure a production line within this output range to maximize efficiency.

I. Core Requirements and Design Considerations

An hourly output of 100-150 tons is considered a medium to large-scale production.

The production line design needs to comprehensively consider the following key points:

• Raw Material Characteristics: Limestone is not very hard, but it may contain a certain amount of moisture and clay, requiring targeted equipment selection.

• Finished Product Requirements: It is necessary to clarify whether the final product is 0-5mm manufactured sand, 10-30mm crushed stone aggregate, or a mixture of various specifications, which determines the process flow.

• Investment and Operating Costs: While ensuring output and quality, priority should be given to equipment with low energy consumption and long service life of wearing parts to reduce long-term operating costs.

II. Classic Process Flow Analysis

A high-efficiency limestone crushing production line typically adopts the principle of "multi-stage crushing combined with screening."

Below are two classic solutions:

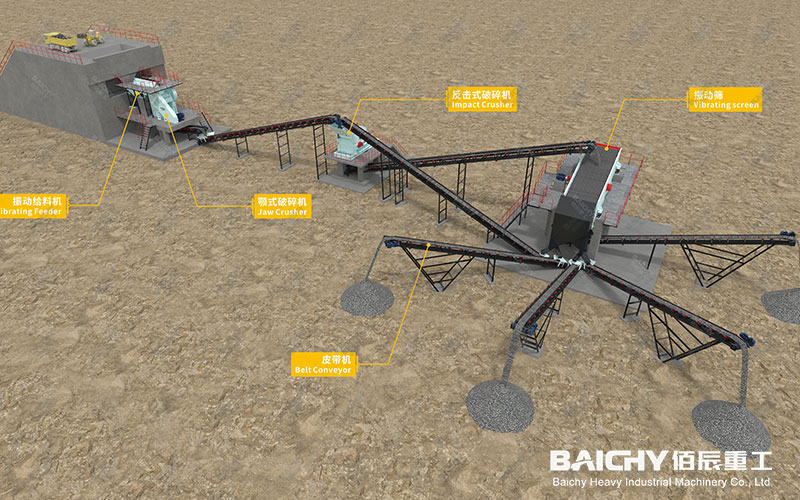

Solution 1: Two-stage crushing process (jaw crusher + impact crusher) – Economical and efficient choice

This is the most commonly used and cost-effective configuration, especially suitable for scenarios where the raw material particle size is not large and the product particle size requirements are not very strict.

1. Feeding: A vibrating feeder uniformly and continuously feeds the limestone from the raw material hopper into the jaw crusher.

2. Coarse crushing: The jaw crusher performs the first stage of crushing, breaking large pieces of limestone (e.g., <630mm) into medium particle size (approximately 100-200mm).

3. Medium and fine crushing: The coarsely crushed material is conveyed by a belt conveyor to the impact crusher. The impact crusher utilizes impact energy for crushing, which is not only highly efficient but also produces finished particles with good shape and low needle-like and flaky content.

4. Screening: The crushed material is graded by a vibrating screen. Finished products meeting specifications are sent to different finished product stockpiles, while oversized particles are returned to the impact crusher for further crushing, forming a closed-loop cycle to ensure uniform product particle size.

Option Two: Three-Stage Crushing Process (Jaw Crusher + Cone Crusher + Sand Making Machine) – The Choice for High-Quality Products

This option is better when there are extremely high requirements for the particle shape and gradation of the finished product (such as for high-grade concrete), or when it is necessary to produce high-quality manufactured sand simultaneously.

1. Coarse and Medium Crushing: The process is the same as in Option One, using a combination of "jaw crusher + cone crusher". The cone crusher is more suitable for crushing hard materials, and it operates stably with good wear resistance. As a medium crushing device, it can effectively reduce the wear of subsequent equipment.

2. Sand Making and Shaping: The material crushed by the cone crusher enters the impact crusher (vertical shaft impact crusher) for fine crushing and shaping, producing high-quality manufactured sand with rounded particle shape and reasonable gradation.

3. Screening: Multi-layer vibrating screens can accurately separate finished products of various specifications, such as 0-5mm, 5-10mm, and 10-20mm, maximizing resource value.

III. Recommended Core Equipment

• Coarse Crushing Equipment: Jaw crushers such as PE-600×900 and PE-750×1060 are ideal choices for processing capacities ranging from 100-150 tons/hour, featuring robust structures and strong crushing force.

• Medium and Fine Crushing Equipment:

◦ Impact Crusher (Option 1): Models such as PF-1214 and PF-1315, with adjustable discharge particle size and excellent product shape.

◦ Cone Crusher (Option 2): Single-cylinder or multi-cylinder hydraulic cone crushers, offering a high degree of automation and stable output.

• Feeding and Screening Equipment: GZD series vibrating feeders and 3YZS series circular vibrating screens ensure continuous and uniform feeding and efficient screening.

IV. Investment Advantages of the Production Line

1. High Output and Efficiency: The compact process design and reasonable equipment matching ensure a consistently stable output of 100-150 tons/hour.

2. High-Quality Finished Products: The finished aggregate has uniform particle size and excellent shape, resulting in strong market competitiveness and higher selling prices.

3. Energy Saving and Environmental Protection: Modern crushing equipment emphasizes energy-saving design and can be equipped with dust removal and noise reduction devices to meet environmental protection requirements.

4. Quick Return on Investment: Low equipment failure rate, highly wear-resistant wear parts, and low maintenance costs help investors quickly recover costs and achieve profitability.

A scientifically designed limestone crushing production line is a systematic project. Choosing the right equipment configuration and process flow is the cornerstone of project success.

If you are planning to invest in a limestone crushing production line with an output of 100-150 tons/hour, please feel free to contact us. Our technical engineers will provide you with a one-on-one customized solution and detailed equipment quotation based on your specific site and needs.