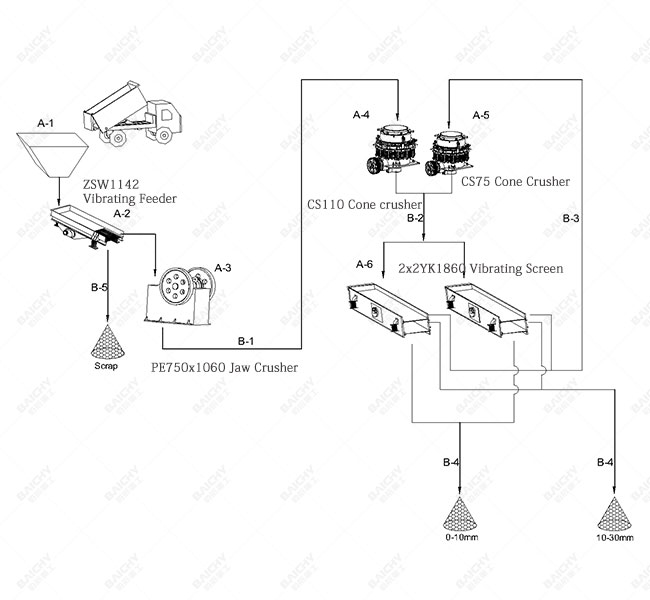

| No. | Equipment | Model | Qty |

|---|---|---|---|

| A-1 | Hopper | LC3000X4000 | 1 |

| A-2 | Vibrating Feeder | ZSW1100X4200 | 1 |

| A-3 | Jaw Crusher | PE750X1060 | 1 |

| A-4 | Cone Crusher | CS160 | 1 |

| A-5 | Cone Crusher | CS75 | 1 |

| A-6 | Vibrating Screen | 2YK1860 | 2 |

| No. | Name | Length | Qty |

|---|---|---|---|

| B-1 | B1000 | 23m | 1 |

| B-2 | B1000 | (21+8)m | 1 |

| B-3 | B650 | (23+8)m | 1 |

| B-4 | B650 | (25+8)m | 2 |

| B-5 | B500 | 15m | 1 |

Addressing the core needs of medium to large-scale sand and gravel aggregate projects, we provide a complete solution from hard rock to high-quality aggregates, ensuring you achieve a stable and reliable output of 150-200 tons/hour at the lowest operating cost, allowing you to quickly gain market share.

• Powerful primary crushing combination: Utilizing a heavy-duty jaw crusher (PE750X1060), specifically designed for high-hardness rocks ≤630mm, ensuring stable and reliable primary crushing and laying a solid foundation for subsequent processes.

• Core crushing process: The classic "jaw crusher + cone crusher" configuration, using the principle of layered crushing, efficiently processes materials such as granite and basalt, achieving a stable production capacity of 180 tons/hour.

• Three-stage crushing precision control: Coarse, medium, and fine crushing are processed in stages, combined with a double-layer high-efficiency vibrating screen (2YK1860), forming a closed-loop system to ensure a stable finished product qualification rate of over 95%.

• Particle shape optimization technology: The produced aggregates have a rounded shape and reasonable gradation, fully meeting the strict requirements of high-end commercial concrete, asphalt mixing plants, and water conservancy projects.

• Equipment reliability design: Core components use special wear-resistant materials, extending their lifespan by more than 50%.

• Intelligent monitoring system: Real-time monitoring of equipment operating status, providing early warning of potential failures, significantly reducing unexpected downtime.

• Actual operating capacity is stable at 150-200 tons/hour, easily exceeding one million tons per year.

• Equipment operating rate is as high as 95%, supporting 24-hour continuous operation.

• Optimized investment costs through reasonable equipment configuration.

• Efficient and energy-saving design reduces operating costs.

• Investment is typically recovered within 12-18 months.

• The same production line can produce finished products of various specifications: 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm.

• Easily adapt to changing market demands and improve profitability.

Facing industry pain points such as low efficiency in hard rock crushing, unstable finished product grading, high equipment maintenance costs, and increasing environmental pressure, we provide a one-stop, highly adaptable, and intelligently operated aggregate production line solution, efficiently transforming your rock resources into high-value aggregates.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Meet our experts and join discussions about solutions to industry challenges.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!