Jaw Crusher for Primary Crushing

In the long chain of mining and aggregate production, the first process often determines the efficiency and cost of the entire production line. As the bottleneck of the crushing process, the selection of primary crushing equipment is crucial.

Among numerous equipment options, jaw crushers have consistently held the top position in the primary crushing stage for decades due to their robust structure, strong processing capacity, and excellent adaptability to harsh working conditions. As a manufacturer with 20 years of experience in mining crushing equipment manufacturing, we will provide you with an in-depth analysis of the core value of this steel giant jaw.

| Key Words | Jaw Crusher for Primary Crushing |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | 100-1200mm |

| Motor Power | 30-280kw |

| Capacity | 0-1200 t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why is the jaw crusher the preferred choice for primary crushing?

The goal of primary crushing is to reduce the size of raw ore, which has varying particle sizes after blasting and can reach up to 1 meter or more, preparing suitable feed for subsequent medium and fine crushing processes. This stage places extremely stringent demands on the equipment:

• High impact load: The material is huge, and the impact force of falling is strong.

• High abrasiveness: Raw ore often contains hard and sharp components.

• High reliability requirements: Once the machine stops, the entire production line will be halted.

The working principle of a jaw crusher simulates the movement of an animal's jaws. Through the periodic reciprocating motion of the movable jaw relative to the fixed jaw, the material is crushed by a combination of compression, splitting, and bending. This direct physical crushing method gives it unparalleled structural simplicity and a natural advantage in processing large blocks of material, perfectly meeting all the stringent requirements of primary crushing.

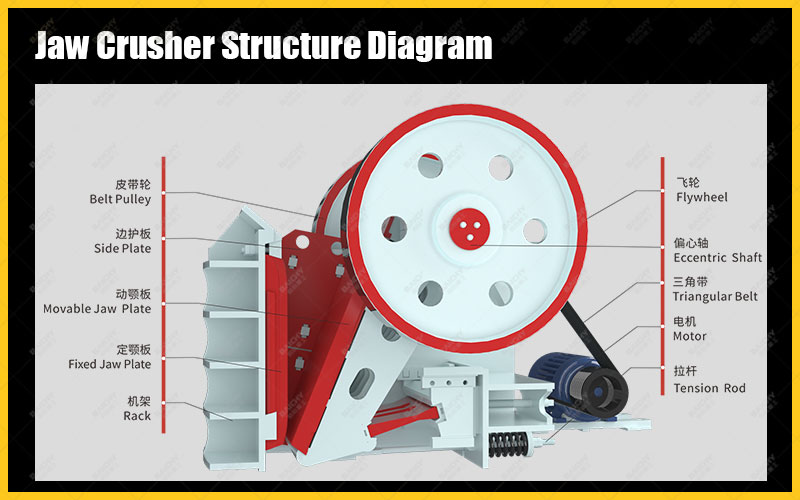

PE jaw crusher structure diagram

Jaw Crusher Overview: The Wisdom of Classic Design

A standard jaw crusher mainly consists of a frame, movable jaw, fixed jaw plate, eccentric shaft, adjustment device, tensioning device, and other core components. Its working cycle is pided into two processes:

1. Working stroke: The motor drives the eccentric shaft, causing the movable jaw plate to move closer to the fixed jaw plate, and the material is crushed between the two jaw plates.

2. Discharge stroke: The movable jaw plate moves away from the fixed jaw plate, and the crushed material moves downward under gravity. Finished products smaller than the discharge opening are discharged from the bottom, while materials that have not reached the required size remain in the crushing chamber and enter the next working cycle to be further crushed. Based on the differences in the movement trajectory of the movable jaw, jaw crushers are mainly pided into two types: double-toggle type (more efficient and higher output) and single-toggle type (less wear and tear, suitable for highly abrasive materials).

Core Advantages: Reliability forged by 20 years of dedicated craftsmanship

With 20 years of technological accumulation and manufacturing expertise, our jaw crushers possess the following outstanding advantages:

• Exceptional robust structure and durability: The heavy-duty frame welded with high-strength steel, combined with a large forged eccentric shaft and high-quality bearings, can withstand the most severe impact loads, ensuring long-term stable operation of the equipment.

• Excellent crushing capacity and high throughput: The deep cavity design and optimized crushing chamber ensure that large materials can be smoothly swallowed and efficiently crushed, providing a continuous and sufficient feed for the production line.

• Wide range of material adaptability: From hard granite and basalt to highly abrasive iron ore and river pebbles, and even construction waste recycling, our crushers can handle them all with ease.

• Simple maintenance and low operating costs: The modular design makes the replacement of wear parts (such as jaw plates) quick and convenient. The optimized crushing chamber shape reduces jaw plate wear, directly lowering the user's long-term operating costs.

• Flexible discharge adjustment: The discharge opening size can be quickly adjusted through a wedge or shim adjustment mechanism, allowing for flexible control of the final product particle size to meet the needs of different downstream processes.

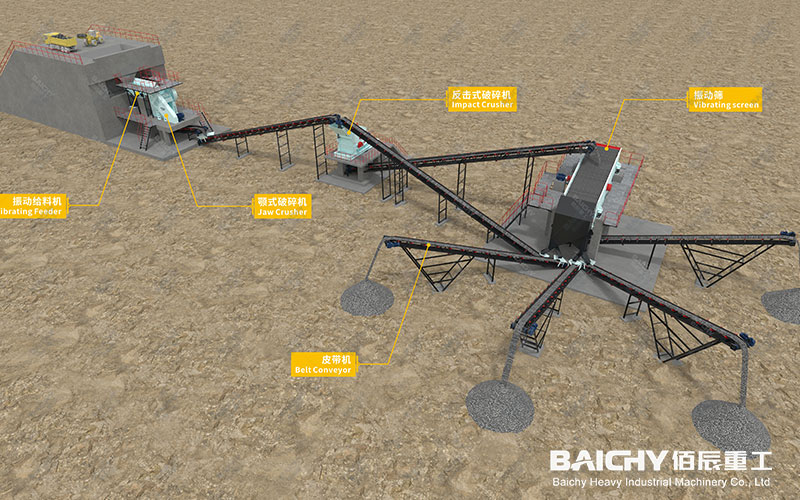

Stationary crushing production line

Practical Cases: Our equipment in action worldwide

Case Study 1: Large Granite Quarry in China

Customer Pain Point: Insufficient capacity of the original equipment, frequent material jamming, and production delays due to maintenance.

Our Solution: Configured a PE-1200×1500 large jaw crusher as the primary crusher.

Results: The hourly processing capacity is stable at 800-1000 tons, perfectly crushing large granite blocks up to 1200mm, and the equipment's continuous operation rate reaches over 95%, becoming the main production force of the quarry.

Case Study 2: Southeast Asian Iron Ore Project

Customer Pain Point: The iron ore is highly abrasive, causing excessive wear and frequent replacement of jaw plates. Our Solution: We provide jaw crushers with specialized high-manganese steel jaw plates and optimized tooth profiles, utilizing a more suitable cavity design to reduce ineffective wear.

Results: Jaw plate lifespan is extended by 40% compared to previous equipment, and the crushing cost per ton of ore is significantly reduced.

Jaw Crushing Plant

Related Equipment Recommendations: Building an Efficient Crushing Production Line

A superior jaw crusher is the first step to success. To build an efficient and profitable production line, we recommend the following supporting solutions:

1. Feeding Equipment: Heavy-duty plate feeders provide uniform and controllable feeding to the jaw crusher, preventing blockages and maximizing its efficiency.

2. Primary Screening: A heavy-duty vibrating screen (such as a grizzly screen) is installed after the jaw crusher to pre-screen out soil and fine materials, reducing the load on the secondary crushing equipment and improving system efficiency.

3. Secondary and Tertiary Crushing Equipment: Can be paired with a cone crusher for processing high-hardness materials, or an impact crusher for processing medium-hardness materials requiring good particle shape.

4. Conveying System: A complete set of high-strength belt conveyors connects each process stage, ensuring smooth material flow.

Frequently Asked Questions (FAQ)

Q1: How to choose the right jaw crusher model?

A: This mainly depends on three key parameters: maximum feed size, required processing capacity (tons/hour), and final product particle size requirements. Our engineers can provide precise selection advice based on your specific material characteristics and production goals.

Q2: What is the normal service life of the jaw plates?

A: This depends on the hardness, abrasiveness of the crushed material, and production volume. Typically, when crushing medium-hardness granite, the jaw plate life is 3-6 months. We offer jaw plates made of various materials (such as standard high-manganese steel, reinforced high-manganese steel, composite alloys, etc.) to suit different working conditions and maximize service life.

Q3: What key points should be noted during equipment operation?

A:

① Ensure uniform feeding, avoiding side feeding or uneven filling.

② Regularly check the wear of wear parts such as jaw plates and side plates, and adjust or replace them promptly.

③ Pay attention to bearing temperature and maintain good lubrication.

④ Regularly check all fasteners for looseness.

Q4: Can you provide customized services?

A: Absolutely. Our 20 years of experience enable us to provide comprehensive customized solutions, from structural reinforcement and corrosion protection to electrical control systems, for special materials, extreme weather conditions, specific installation space limitations, or automation control requirements.

Q5: What are the advantages of jaw crushers compared to impact crushers in primary crushing?

A: In the primary crushing stage, the material blocks are large and hard. Jaw crushers use the principle of compression crushing, have a more robust structure, and are more suitable for processing large, high-hardness materials, and are not sensitive to the moisture content of the material. Impact crushers are more suitable for medium and fine crushing, achieving better particle shape through impact crushing, but they are difficult to directly process extra-large, high-hardness raw ore.