Jaw Crusher | Primary Crusher in Mining & Aggregate

In industrial fields such as mining, aggregate processing, and construction waste recycling, primary crushing is the first and most critical step in the entire production process. The jaw crusher, as the most widely used and longest-standing primary crushing equipment, directly determines the efficiency of subsequent processes and the quality of the final product.

For production lines that pursue high output, high stability, and low operating costs, choosing a high-quality jaw crusher is the cornerstone of success. As a manufacturer with 20 years of experience in mining crushing equipment manufacturing, we deeply understand its core value.

| Key Words | Primary Crusher in Mining & Aggregate |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | 100-1200mm |

| Motor Power | 30-280kw |

| Capacity | 0-1200 t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Equipment Overview

The jaw crusher, commonly known as the tiger's mouth, works by using the periodic reciprocating motion between two jaw plates (a movable jaw and a fixed jaw) to compress, bend, and split the material, thus achieving crushing. It is renowned for its robust structure, strong adaptability, relatively simple maintenance, and wide range of materials it can handle (from extremely hard granite to recycled construction concrete), making it a true workhorse of primary crushing.

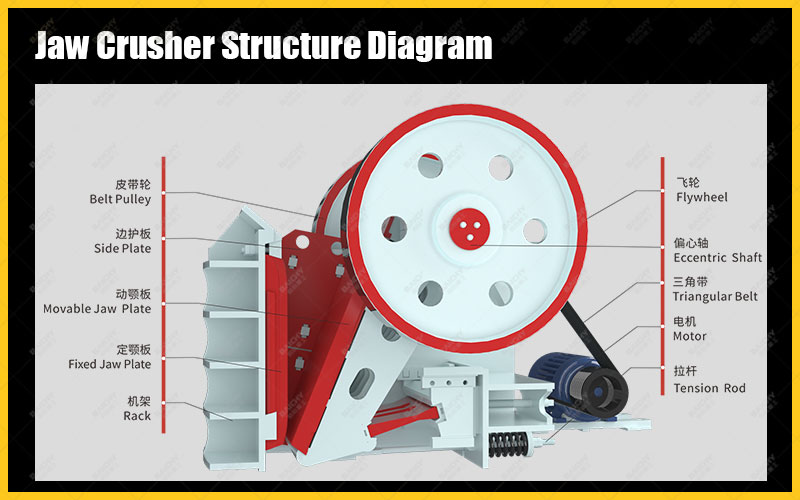

PE jaw crusher structure diagram

Core Advantages

With twenty years of technological accumulation and continuous innovation, our jaw crushers possess the following significant advantages:

- Exceptional Durability and Reliability: Using high-strength steel plate welded frames, large eccentric shaft forgings, and high-quality bearings, the equipment ensures long-term stable operation under heavy loads and impact loads, effectively reducing the risk of unexpected downtime.

- Excellent Crushing Efficiency and High Output: The optimized cavity design provides a deeper crushing chamber and no dead zones, combined with a larger feed opening size, achieving a higher crushing ratio and greater processing capacity, increasing the overall production line capacity.

- Lower Overall Operating Costs: Key wear parts (such as jaw plates) use new composite high-manganese steel materials, significantly improving wear resistance and extending service life, significantly reducing the cost of spare parts per ton of material crushed. The modular design also makes maintenance and replacement more convenient.

- Outstanding Material Adaptability: It can effectively handle materials of various hardnesses, moisture levels, and even those containing a certain degree of stickiness, making it a reliable choice for primary crushing stages dealing with complex material conditions. - Intelligence and Environmental Protection: Optional features include an automatic lubrication system, condition monitoring module, and advanced dust control devices, enhancing the intelligent management of the equipment while meeting increasingly stringent environmental requirements.

Stationary crushing production line

Application Cases

Our jaw crushers have been successfully applied in hundreds of projects worldwide:

- Case 1: A large granite aggregate project in North China. A PEV-1200×1500 large jaw crusher was used as the primary crusher, with an average daily processing capacity exceeding 20,000 tons. The output particle size was consistently below 250mm, creating perfect conditions for subsequent secondary and tertiary crushing processes. The customer highly praised the equipment's high stability and low jaw plate wear.

- Case 2: A iron ore mining project in Southeast Asia. In a harsh environment with high temperature and humidity, our jaw crusher, thanks to its excellent dustproof sealing and anti-corrosion treatment, operated continuously for over 18 months without major repairs, becoming a core contributor to the customer's production line.

Related Equipment Recommendations

An efficient crushing system usually consists of multiple stages of equipment working together. After the jaw crusher completes primary crushing, we recommend considering the following equipment to form an optimal production line, based on your final product requirements:

- Secondary Crushing Equipment: Cone crusher (suitable for medium to high hardness materials) or impact crusher (suitable for medium to low hardness materials, with good particle shape).

- Fine Crushing and Shaping Equipment: Vertical shaft impact crusher (for sand making and shaping).

- Pre-feeding Equipment: Heavy-duty plate feeder, ensuring uniform and continuous feeding to the jaw crusher to maximize its efficiency.

- Post-screening Equipment: Circular vibrating screen or multi-layer linear vibrating screen for material classification.

Frequently Asked Questions (FAQ)

Q1: How do I choose the right jaw crusher model based on my production capacity requirements?

A: This is mainly determined by your planned maximum feed particle size, required output particle size, and target hourly output (tons/hour). Our engineering team can provide professional selection calculations and solution recommendations based on your specific material characteristics and production plan.

Q2: What are the core wear parts of a jaw crusher? Q: How often do the parts typically need to be replaced?

A: The main wear parts are the fixed jaw plate and the movable jaw plate. Their service life is directly related to the hardness and abrasiveness of the processed material, the equipment operating time, and the wear resistance of the jaw plate material, ranging from a few hundred hours to several thousand hours. Our special alloy jaw plates provide industry-leading wear life.

Q3: Does the equipment support mobile installation?

A: Yes. In addition to traditional fixed installation, our jaw crusher core can be integrated into wheeled or tracked mobile crushing stations, forming a mobile jaw crushing station. This is particularly suitable for operations requiring relocation, such as mining stripping and on-site processing of construction waste, greatly improving project flexibility and investment efficiency.

Q4: As a manufacturer with 20 years of experience, what kind of after-sales service do you provide?

A: We provide turnkey services, from project consulting, solution design, installation guidance, commissioning and operation, to operator training. We have established a global network of spare parts centers, promising a rapid response and providing long-term equipment optimization and technical support to ensure maximum value for our customers' production lines.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.