What is Crush and Run Gravel?

Crush and Run Gravel: A Reliable Choice and Professional Equipment Analysis for Building Foundations

As a manufacturer with 20 years of experience in the field of mining crushing and grinding equipment, we deeply understand the importance of high-quality aggregates for the success of engineering projects. Today, we will delve into a material indispensable in foundation constructionCrush and Run Graveland analyze its production and application from the perspective of an equipment manufacturer.

What is Crush and Run Gravel?

Crush and Run Gravel, often referred to as compacted stone, CR-6, or 21A stone, is an aggregate made by mixing crushed limestone, granite, or other hard rocks with stone powder (stone chips). Its name intuitively describes its characteristics: it can be used directly after crushing (Crush) (Run), without further screening or separation.

This mixture of crushed stone and stone powder, after compaction, forms an extremely strong, stable, and well-drained base course. The stone powder fills the voids between the larger crushed stones, and under the combined action of gravity and moisture, they are tightly bonded together, forming a dense, compacted layer similar to concrete.

Key Advantages of Crush and Run Gravel

Why is Crush and Run Gravel so favored by contractors and engineers? Its advantages are primarily reflected in the following aspects:

• Superior Stability and Load-Bearing Capacity: Once fully compacted, it forms a near-rigid base layer, effectively distributing the load from the upper layers and preventing road or foundation subsidence. This high stability and load-bearing capacity are its core value.

• Excellent Drainage Performance: Compared to pure soil or certain fine aggregates, its structure allows water to pass through, reducing water accumulation and frost heave damage, and improving project durability.

• Economical and Efficient, Easy to Install: As a single material, its procurement and transportation costs are relatively low, and the laying and compaction processes are simple, significantly saving time and labor costs.

• Versatile Applications: It is an ideal base layer material for projects such as driveways, paths, parking lots, building foundations, and pipe backfilling.

High-Quality Crush and Run Gravel Production Requires Specialized Equipment

The quality of Crush and Run Gravel directly depends on its raw materials and production processes. This is where our 20 years of professional experience come into play.

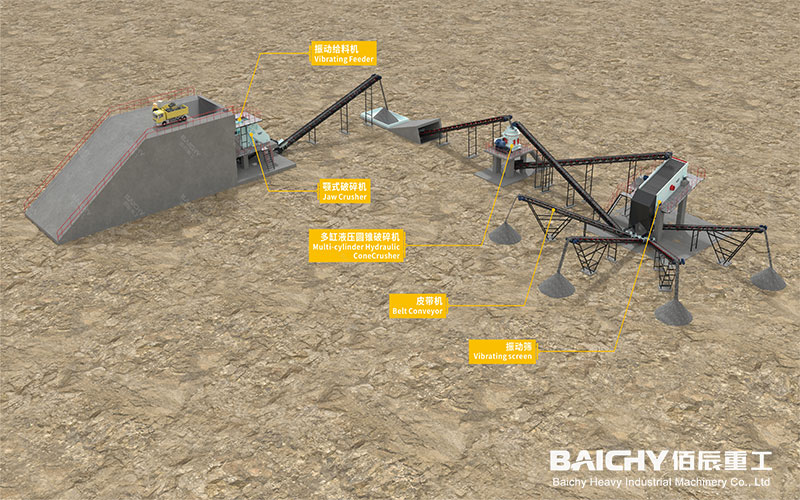

Producing high-quality Crush and Run aggregates hinges on precise control of the crushing ratio, particle size distribution, and stone powder content. A high-efficiency, stable jaw crusher handles the primary crushing of the raw stone, while a cone crusher or impact crusher performs medium to fine crushing, producing the appropriate amount of stone powder. A high-efficiency vibrating screen ensures the final mixture meets standard particle size distribution (typically 0-1 inch or 0-1.5 inch), achieving the ideal crushed stone to stone powder ratio.

Case Study: How Equipment Facilitates High-Quality Aggregate Production

We once provided a complete crushing and screening production line for a large aggregate producer in the southeastern United States. Their core requirement was the stable production of Crush and Run Gravel (model CR-6) that met local DOT (Department of Transportation) standards.

By configuring our heavy-duty jaw crusher as the primary crusher, combined with a multi-cylinder hydraulic cone crusher for secondary crushing, and optimizing screen sizes, the customer not only consistently obtained ideal products with perfect particle size and a stone powder content of approximately 10-15%, but also achieved extremely high production line reliability, reduced maintenance costs, and helped secure multiple state highway base material supply contracts. This proves that reliable crushing and grinding equipment is the cornerstone of high-quality aggregates.

Heavy-duty jaw crusher

Recommended Equipment Solutions for Your Crush and Run Production

Based on different capacities and raw material hardness, we recommend the following equipment combinations:

• Medium Capacity Standard Solution:

◦ Primary Crushing: PE Series Jaw Crusher Provides powerful initial crushing force.

◦ Secondary Crushing and Shaping: HPT Multi-cylinder Hydraulic Cone Crusher Efficiently produces cubic particles and controls stone powder generation.

◦ Screening: 3YK Series Circular Vibrating Screen Precisely grades to ensure product specifications.

• High-Capacity Hard Rock Solution:

◦ Primary Crushing: Jaw crusher designed for highly abrasive granite and basalt.

◦ Secondary Crushing: S single-cylinder hydraulic cone crusher achieving high throughput with low operating costs.

◦ Screening and Conveying: Customized multi-layer linear vibrating screen and belt conveyor system.

Frequently Asked Questions (FAQ) about Crush and Run Gravel

Q1: What is the difference between Crush and Run Gravel and Clean Stone?

A1: The main difference lies in the stone powder content. Clean Stone, after washing or rigorous screening, contains almost no stone powder and has poor intergranular bonding, often used for drainage layers or decorative purposes. Crush and Run Gravel intentionally retains stone powder, resulting in tight bonding after compaction, specifically designed for load-bearing base layers. Stone powder is crucial for stability.

Q2: How thick should Crush and Run Gravel be laid? How to properly compact it?

A2: For general uses such as driveways, a compacted thickness of 4-6 inches is recommended. First, level and compact the subgrade, then lay the material in layers (each layer no more than 2 inches), compacting each layer thoroughly using a plate compactor or roller. Spraying a small amount of water helps the stone powder adhere and improves the final density.

Q3: As a manufacturer, how do you control the stone powder ratio in the Crush and Run for optimal results?

A3: This requires adjusting the crushing equipment parameters and screening process. Using a cone crusher or impact crusher can increase finesse output. The key is selecting the correct combination of crushing chamber type and screen size. Our engineers can provide process commissioning services, analyzing raw materials and conducting tests to find the optimal equipment setup, ensuring continuous product gradation and a stable stone powder content within the ideal range (typically 8-15%), thereby guaranteeing the final compaction strength and stability of the product.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!