Stone Crushing Plant PDF,Download ↓↓↓

In the fields of building aggregates and infrastructure construction, limestone is a crucial raw material, and its processing efficiency and finished product quality directly impact project costs and benefits. For projects aiming for a production capacity of 250 tons per hour and requiring the production of pure 0-19mm finished aggregate, selecting a suitable crushing production line configuration is the cornerstone of success.

Among these, the process of using a jaw crusher as primary crushing, combined with a cone crusher for secondary crushing, is hailed as the gold standard for hard ore crushing. This article will delve into this approach, particularly for resource-rich markets like South Africa, providing a complete guide from analysis to implementation.

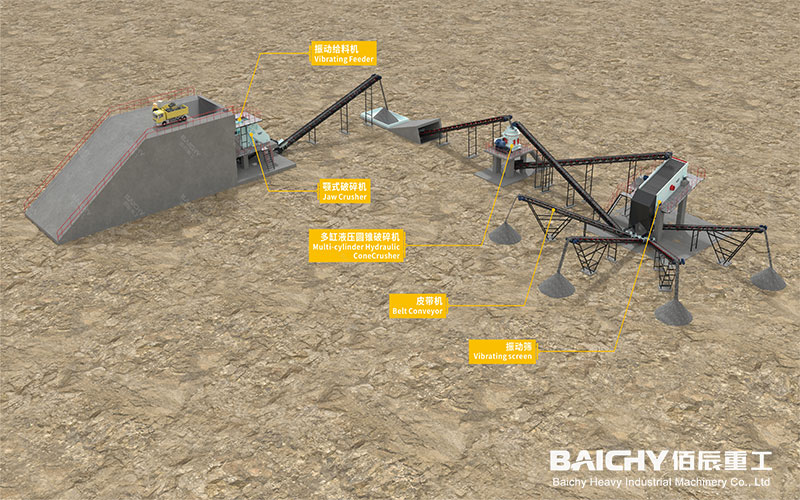

250tph Limestone Crushing Production Line Solution

This classic 250tph limestone crushing production line's core design logic lies in segmented crushing, closed-loop circulation to achieve high efficiency, energy saving, and high-quality finished products.

• Primary Crushing (Coarse Crushing): Large pieces of limestone raw material (typically over 800mm) are evenly fed into the jaw crusher by a vibrating feeder. The jaw crusher, with its powerful compressive crushing force, crushes the raw material to a medium particle size of less than 250mm, preparing it for the next stage.

Primary Jaw Crusher

• Secondary Crushing and Screening (Medium and Fine Crushing and Grading): After being crushed by the jaw crusher, the material is pre-screened to remove some qualified fines and soil before entering the cone crusher. The cone crusher utilizes the principle of layered crushing to further refine and shape the material. Subsequently, all material enters a multi-layer vibrating screen for rigorous screening. Qualified finished products of 0-19mm are separated, while materials larger than this size are returned to the cone crusher for further crushing via a return system, forming a highly efficient closed-loop circulation system that ensures precise and controllable particle size.

Hydraulic Cone Crusher

Significant Advantages of this Configuration

Choosing the combination of a jaw crusher and a cone crusher, especially for limestone crushing, offers multiple competitive advantages:

1. High Reliability and Powerful Performance: The jaw crusher has a robust structure, excels at handling large and hard raw materials, and has a low failure rate, making it an ideal primary crushing equipment. The cone crusher is extremely efficient in the medium and fine crushing stage, producing products with excellent particle shape and low needle-like and flaky content.

2. Superior Finished Product Quality: The cone crusher's layered crushing method produces high-quality cubic, well-graded aggregates, particularly suitable for high-standard commercial concrete and asphalt pavements.

3. High Efficiency, Energy Saving, and Low-Cost Operation: The closed-loop circulation system minimizes equipment idling and over-crushing, resulting in lower overall power consumption. Simultaneously, the high degree of automation reduces labor costs.

4. Strong Adaptability: This solution can handle not only limestone but also, with slight adjustments, other ores of medium to high hardness such as granite and basalt, leaving room for future business expansion for investors.

Case Study Insights: Key Points for Localization Implementation in South Africa

The key to successfully deploying such a production line in South Africa lies in global standards, localized adaptation.

• Power Solutions: South Africa's unstable power grid must be considered. In successful cases, project owners typically equip the entire 250tph crushing production line with high-power diesel generator sets as backup power to ensure production continuity.

• Technical Services and Spare Parts: Choosing equipment suppliers with established dealer networks, local warehouses, and professional technical teams in South Africa is crucial. This ensures smooth installation and commissioning, and allows for rapid replacement of wear parts (such as jaw plates and crushing walls), minimizing downtime.

• Environmental and Community Relations: Proactive investment in dust control (equipped with spray or dust suppression systems) and noise management helps secure operating permits and maintain good community relations, which are the invisible cornerstones of long-term stable operation.

Equipment Selection and Recommendations

For a capacity target of 250 tph, the following equipment selection range is recommended:

• Primary Jaw Crusher: Models with a feed opening size of 1200mm x 1500mm are recommended, such as the PE-1200×1500 or equivalent international specifications, to ensure stable reception of large raw materials.

• Secondary Cone Crusher: Single-cylinder or multi-cylinder hydraulic cone crushers are recommended, with models in the HST-315 or HP-300 range. The hydraulic system facilitates adjustment of the discharge opening and clearing chamber, offering a high degree of automation.

• Core Screening Equipment: For pre-screening and finished product screening, heavy-duty vibrating screens such as the 2YK-2470 and 3YK-3070 are recommended, offering high screening efficiency and durability.

Frequently Asked Questions (FAQ)

Q1: How much site and infrastructure investment is required for this 250tph production line?

A1: This depends on the compactness of the equipment layout. Typically, a flat site at least 100 meters long and 50 meters wide is needed, including the raw material storage yard, production line, and finished product stockpile. Infrastructure investment mainly includes concrete foundations for the equipment, conveyor corridors, and electrical control rooms, usually accounting for 15%-25% of the total equipment investment.

Q2: Can the final product be adjusted? For example, simultaneously producing 0-5mm stone powder and 10-20mm aggregate?

A2: Absolutely. This is precisely the advantage of the multi-layer vibrating screen and closed-circuit system in this solution. By changing the screen size, you can flexibly adjust the proportions of different finished product specifications (e.g., 0-5mm, 5-10mm, 10-19mm) to meet perse market demands and maximize profits.

Q3: In South Africa, what is the typical delivery and commissioning cycle for equipment?

A3: The cycle varies depending on the supplier. From order placement to equipment shipping to major South African ports, it typically takes 2-4 months. On-site installation, commissioning, and trial operation generally take 1-2 months. Choosing a supplier that provides turnkey services allows them to manage the entire process, significantly shortening the overall cycle and reducing coordination risks.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!