Crush and Run Gravel

When people talk about Crush and Run Gravel, they often think of driveways. But as equipment manufacturers, we see a much broader range of applications. This versatile material is playing a crucial role in large-scale infrastructure and commercial projects, which places higher demands on production equipment. Let's explore its high-end applications.

Redefining: From Residential Material to Engineering Substrates

Crush and Run Gravel is essentially a self-bonding, high-density base material. This characteristic extends it beyond residential applications, making it ideal for engineering projects requiring rapid construction, high load-bearing capacity, and excellent drainage. Its engineering applicability is constantly being explored.

High-End Application Scenarios: Where is a Super Crush and Run Needed?

1. Base Layer for Logistics Warehouse Flooring

Modern logistics warehouse floors need to withstand the cyclical loads of giant racks and heavy forklifts. The requirements for uniform settlement and fatigue resistance of the base layer are extremely high. Using high-performance Crush and Run with strict gradation control as a compacted base layer provides stability comparable to concrete, at a lower cost and faster construction. This requires manufacturers to ensure extremely high consistency across each batch.

2. Backfilling and Stabilization of Wind Turbine Foundations

Every wind turbine requires an extremely stable foundation. Before and after pouring the massive concrete foundation, Crush and Run is commonly used for backfilling and site leveling. It allows for rapid drainage, preventing water accumulation around the foundation and softening the soil, and helps stabilize the entire foundation structure through strong lateral restraint. These projects are typically located in remote areas, posing a severe test to the material's on-site compaction performance and long-term durability.

3. Temporary Construction Platforms and Heavy Equipment Access

In swampy, soft soil, or conventional construction sites, temporary access roads are needed for heavy equipment such as cranes and pile drivers. Crush and Run is the preferred choice due to its superior load-bearing capacity and rapid installation characteristics. It disperses concentrated loads, preventing equipment from sinking. This application requires materials with extremely high initial load-bearing capacity and resistance to deformation.

Equipment Challenges in Producing Engineering-Grade Crush and Run

Meeting these high-end applications means that the product cannot just be good enough, it must be precisely up to standard. This presents new challenges for the production line:

• Challenge 1: Extreme Granularity Consistency More sophisticated crushers and screening systems are needed to ensure that over 99% of the particles fall within design specifications.

• Challenge 2: Coping with perse Standards. Different engineering clients may have specific gradation curves (such as US ASTM and various state DOT standards). The production line needs to be flexible and adaptable.

• Challenge 3: Large-Scale Stable Supply. Large-scale projects consume huge amounts of materials, requiring equipment to operate continuously at high loads with uninterrupted stability; reliability is paramount.

Case Study: Supplying Materials for an Interstate Highway Expansion Project

Cone Crusher

One of our clients successfully won a contract to supply base materials for an interstate highway expansion project. The project required CR-6 to fully comply with stringent state Department of Transportation (DOT) specifications. We designed a dedicated production line with a capacity of 500 tons per hour, featuring two large cone crushers operating in parallel and equipped with dual vibrating screens for simultaneous screening.

This configuration not only ensured tremendous production capacity, but more importantly, it ensured that when one machine underwent scheduled maintenance, the other could still operate at full capacity, achieving zero supply interruption risk and guaranteeing project deadlines. This production line became the ticket for our client to undertake large-scale government projects.

Recommended: Equipment Solutions for Large-Scale Engineering Supply

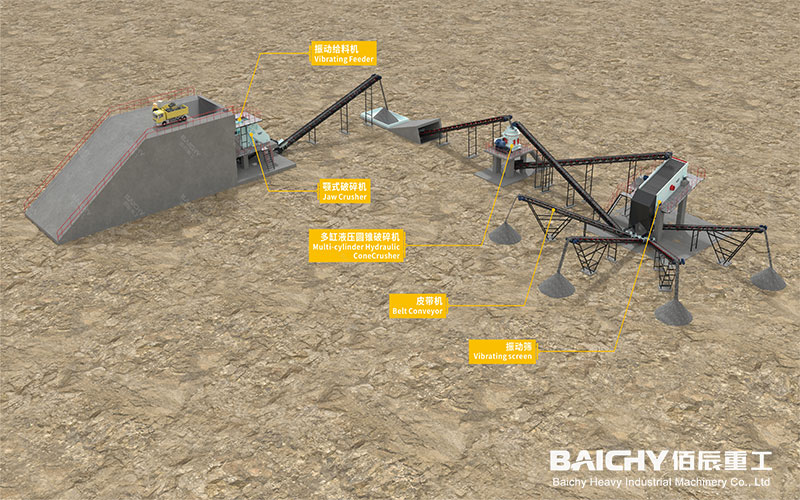

High-Capacity and Stable Solution: Large gyratory crusher (primary) + 2 multi-cylinder cone crushers (secondary parallel) + multi-layer heavy-duty linear screen.

Mobile and Flexible Solution: If projects are dispersed, a tire-mounted mobile crushing and screening station can be used, directly stationed near the mining area or construction site, saving huge transportation costs and providing on-site flexibility.

Core Quality Control: An automated sampling and rapid laboratory testing system is essential to ensure traceability of each batch's quality.

FAQ: Three Questions about the Market and Applications

Q1: Our Crush and Run primarily supplies the residential market. What should be the first step in entering the engineering sector?

A1: The first step is to invest in quality testing and certification. Establish an in-house laboratory and rigorously test the gradation, compaction (Proctor value), and California Load-Bearing Ratio (CBR) of each batch of products according to ASTM or local engineering standards. Proving your products meet engineering standards with data is more effective than any sales pitch.

Q2: Engineering clients are very price-sensitive. Is the return on investment for our high-end equipment high?

A2: Extremely high. Engineering contracts are typically large, long-term, and involve stable payments. A highly reliable, high-capacity machine ensures you fulfill contracts more promptly and at a lower cost per ton, building reputation and securing long-term partnerships. This elevates you from piecework sales to the level of a supply chain partner, resulting in a completely different profit model.

Q3: Are there subtle differences in Crush and Run specifications for different engineering applications?

A3: Yes, this is crucial. For example, materials used in heavy equipment aisles may require a slightly larger maximum particle size (e.g., 1.5 inches) to provide a stronger skeleton effect; while materials used in subflooring may emphasize a continuous 0-1 inch gradation for the smoothest compacted surface. Understanding these details and offering the ability to customize gradations is key to standing out.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!