Gold Pan Mill - High Efficiency Wet Grinding Solutions

Gold Panning Mill: A Revolutionary Solution Leading the Modern Era of High-Efficiency Wet Grinding

In the vast world of mineral processing, efficient wet grinding is a critical link in determining gold recovery rates and production efficiency. As a mineral processing equipment manufacturer with 20 years of experience, we understand what a reliable, efficient, and economical grinding equipment means to mining projects. Today, we will delve into the wet pan mill, also known as the gold grinding mill, and analyze why it has become the ideal choice for small and medium-sized gold, silver, copper, and lead-zinc mines.

I. In-Depth Analysis of Wet Pan Mills

What is a Wet Pan Mill?

A wet pan mill, often called a gold panning mill or gold wet grinding mill, is a traditional rotating drum grinding equipment. It grinds, crushes, and mixes ore materials through the rotation and rolling of two heavy grinding wheels within a circular grinding pan. Its unique wet working method, which involves continuously adding water during the grinding process, forms a slurry, effectively preventing dust pollution and optimizing grinding efficiency and subsequent extraction processes.

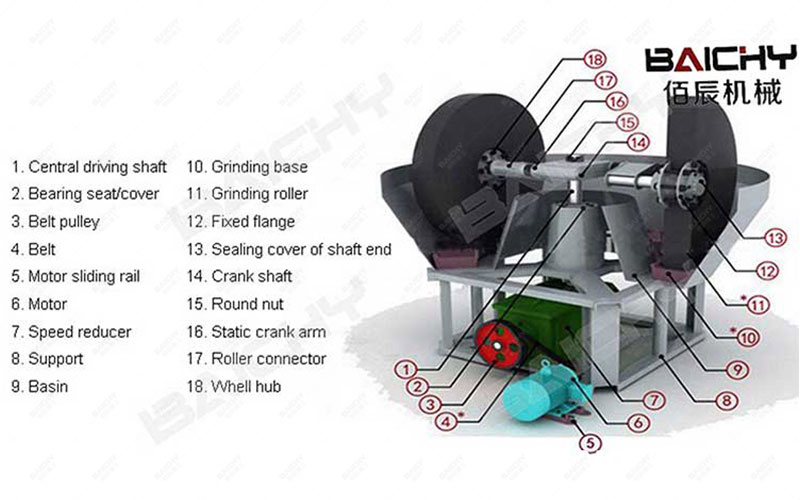

Structural diagram of a wet type gold grinding machine

Overview of Working Principle

The core power of the equipment is transmitted through a motor, driving the grinding wheels on the horizontal shaft to revolve and rotate within the grinding pan. The ore to be crushed and water are continuously fed from the upper feed port, and are repeatedly crushed and ground under the action of gravity and rotational force of the grinding wheels. The slurry that meets the fineness requirements is discharged from the overflow port at the edge of the grinding pan and enters the next classification or separation process. Its structure is simple, but the grinding force is concentrated, making it particularly suitable for processing brittle gold and silver ores with natural cleavage planes.

II. Why Choose Our Wet Pan Mill? A Glimpse of Core Advantages

After 20 years of design and process innovation, our gold panning mills stand out among similar products, bringing tangible value to our customers.

• Excellent Grinding Efficiency and High Output: The grinding wheels and grinding pan are made of high-chromium alloy or manganese steel, which have high hardness and wear resistance, ensuring powerful crushing of the ore. The optimized grinding wheel size and counterweight design significantly increase the processing capacity per unit time, guaranteeing high-efficiency wet grinding. • Unparalleled Return on Investment: Compared to large ball mills, wet grinding disc mills have lower purchase costs, simpler installation requirements, and lower power consumption. Their ease of operation and maintenance significantly reduces subsequent operating and labor costs, making them particularly suitable for customers with limited capital or those processing medium-sized ore deposits.

• Excellent Environmental Performance and Adaptability: The fully enclosed wet grinding process completely eliminates dust, resulting in a clean working environment. The equipment has a wide adaptability to feed particle size, and can be used for both fine crushing of ore and direct fine grinding before whole-ore cyanidation. Its robust structure ensures reliable operation even in areas with unstable power supply or remote locations.

• Effective Improvement of Gold Recovery Rate: The slurry produced by wet grinding has good fluidity, allowing for sufficient liberation of gold particles, creating optimal conditions for subsequent amalgamation, cyanidation, or gravity separation, thereby directly improving the final gold recovery rate.

Gold grinding machine customer site

III. Success Stories: Trust from Africa to South America

Our wet grinding disc mills have been exported to over 30 countries and regions worldwide.

• Case Study 1: Tanzania Gold Mine Project: The client originally used traditional stamp mills, which were inefficient. We provided them with two 1200-type wet grinding disc mills for tailings reprocessing, achieving a daily processing capacity of 50 tons and a 25% increase in gold recovery rate. The equipment paid for itself within two years.

• Case Study 2: Small Silver Mine Processing Plant in Peru: At an altitude of 4000 meters, our disc mill, thanks to its excellent stability and resistance to harsh environments, operated continuously for over 8000 hours before the core wear parts needed their first replacement, earning high praise from the client.

IV. Related Equipment Recommendations: Building a Complete Mineral Processing Flow

An efficient gold panning disc mill is the core, but a smooth mineral processing production line requires the perfect coordination of other equipment. We also provide:

• Jaw Crusher: Used for primary coarse crushing of ore, providing the disc mill with a suitable feed particle size.

• Shaking Table/Centrifugal Concentrator: Used for gravity recovery of coarse free gold from the slurry discharged from the disc mill. • Agitation Leaching Tank/Desorption Electrolysis System: Used for processing fine-grained ore pulp after grinding in the disc mill, for cyanide gold extraction.

V. Frequently Asked Questions (FAQ)

Q1: Can the wet disc mill process ores other than gold ore?

A: Absolutely. Although it is most widely used in the gold mining industry, it is also very suitable for fine grinding of various metal ores such as silver, copper, lead, zinc, iron, and molybdenum, and performs exceptionally well in small and medium-sized processing plants and experimental plants.

Q2: What is the lifespan of the wear parts of the equipment? Is replacement complicated?

A: Our grinding wheels and grinding discs are cast using a special alloy process, and their service life far exceeds that of ordinary products on the market. Under normal grinding conditions for gold ore (hardness approximately 6-7), they can operate continuously for 6-12 months. The replacement process is designed to be simple and can usually be completed with remote guidance from our engineers, minimizing downtime.

Q3: How do I determine the appropriate disc mill model and quantity for my mine?

A: This requires scientific calculation based on your raw ore processing capacity, ore hardness, feed particle size, and target fineness. We provide free technical consulting services. You only need to provide basic mineral assay reports and production requirements, and our 20-year experienced technical team will customize the most economical configuration plan for you.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.