1200 Wet Pan Mill Gold Ore with High Quality

How the 1200-Type Wet Disc Mill Unlocks the Maximum Value of High-Quality Gold Ore

In the precise process chain of gold ore beneficiation, crushing and grinding are crucial preliminary steps that determine the degree of gold mineral liberation and the final recovery rate. Especially for high-quality gold ore, its high economic value demands almost stringent requirements for the efficiency, stability, and product fineness control of grinding equipment. As a beneficiation equipment manufacturer with 20 years of experience, we will delve into why the 1200-type wet disc mill is the ideal core equipment for processing such materials.

| Key Words | 1200 Wet Pan Mill Gold Ore with High Quality |

|---|---|

| Product Model | Wet Pan Mill |

| Feed Size | ≤30mm |

| Motor Power | 7.5kw |

| Capacity | 10t/h |

| Core Functions | Kinetic energy transfer + abrasion + hydraulic classification |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. In-Depth Analysis: Why Does High-Quality Gold Ore Require Professional Grinding?

High-quality gold ore usually means a higher grade of raw ore, but its occurrence may be complex gold may exist in the form of fine particles or inclusions within gangue minerals such as quartz and pyrite. To achieve efficient cyanidation or flotation, the ore must be ground to a sufficient degree of liberation, while avoiding over-grinding that produces slime, which affects subsequent leaching or flotation results.

Traditional ball mills often have high energy consumption and are prone to over-grinding when dealing with fine grinding requirements. The wet disc mill, especially the large 1200-type model, uses a unique grinding principle, employing the compressive and shearing forces between the hydraulically applied grinding rollers and the rotating grinding disc to achieve efficient and controllable fine grinding of the material. It perfectly meets the core requirements of "fine, uniform, and economical" grinding for high-quality gold ore.

II. Equipment Overview: The Core Design of the 1200-Type Wet Disc Mill

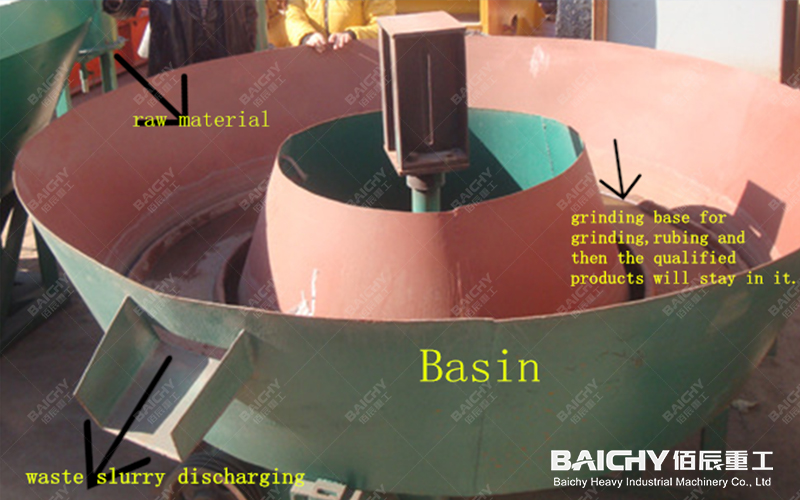

The 1200-type wet disc mill, whose model number usually refers to a grinding disc diameter of 1200 millimeters, is a medium-to-large industrial-grade grinding equipment. It mainly consists of a power system, a transmission system, a grinding assembly (grinding disc and grinding rollers), a hydraulic pressurization system, feeding and discharge devices, and an automatic control system.

Gold grinding machine structural diagram

• Working Principle: The ore slurry is fed from the top into the center of the rotating grinding disc, and under the action of centrifugal force, enters the grinding zone between the grinding rollers and the grinding disc. The hydraulic system provides huge and adjustable grinding pressure to the grinding rollers, crushing and grinding the material. The finely ground material is thrown out at the edges and carried away by the circulating slurry.

• Key Features: Compact design, small footprint; fully enclosed structure, no dust pollution; wet operation, combining grinding and mixing functions, directly preparing qualified slurry for subsequent operations.

Gold grinding machine customer site

III. Core Advantages: Why choose our 1200 wet disc mill for processing gold ore?

1. Excellent grinding efficiency and energy saving performance: Compared with traditional ball mills, it can save up to 30%-50% energy at the same fineness. Its material bed crushing principle has extremely high energy utilization efficiency, directly reducing the production cost of high-quality gold ore processing.

2. Precise product particle size control and narrower particle size distribution: By flexibly adjusting the grinding roller pressure, grinding disc speed, and slurry circulation volume, the required fineness can be easily obtained (usually -400 mesh accounts for more than 90%), and the product particle size is uniform, with less over-grinding, which is conducive to the efficient leaching of gold.

3. High stability and low maintenance costs: The core wear-resistant parts (such as grinding roller bushings and grinding disc liners) are made of high-chromium alloy or special ceramic composite materials, which have extremely strong wear resistance and long service life. The modular design makes maintenance and replacement more convenient, maximizing continuous production.

4. Intelligent automatic control: Integrated PLC control system can monitor key parameters such as spindle current, bearing temperature, hydraulic pressure, and feed rate in real time, realizing automatic adjustment and fault warning, ensuring that the equipment serves your high-quality gold ore processing under optimal working conditions.

5. Strong adaptability: It is not only suitable for high-quality gold ore, but also performs excellently in fine grinding operations of various hard and abrasive metal and non-metallic ores.

IV. Successful Application Cases

Our successful transformation project at a large gold mine in Central Asia is quite representative. The mine originally used a single-stage ball mill + classification process to process high-quality quartz vein gold ore, with a target grinding fineness of -325 mesh accounting for 85%, but there were problems such as high energy consumption, low classification efficiency, and unstable operation.

• Renovation Plan: We provided a "package solution" consisting of two 1200-type wet disc mills, configured in parallel, to replace the original complex system.

• Operating Results:

◦ Product fineness consistently reached over 90% at -325 mesh, and the gold leaching rate increased from 86.5% to 91.8%.

◦ System power consumption was reduced by approximately 40%.

◦ The equipment operated smoothly with an annual operating rate exceeding 95%, and maintenance workload was significantly reduced.

◦ The investment payback period was only 16 months, and the customer was extremely satisfied with the overall benefits.

V. Recommended Related Equipment

To maximize the efficiency of the 1200-type wet disc mill, we recommend the following equipment to form a high-efficiency grinding circuit:

• Pre-crushing: High-efficiency jaw crusher or cone crusher to ensure uniform feed particle size (usually less than 10mm).

• Classification Equipment: High-frequency fine screen or hydrocyclone to form a closed circuit with the disc mill and control the final product particle size.

• Slurry Transportation and Preparation: Wear-resistant slurry pump and high-efficiency mixing tank to ensure stable slurry supply and thorough reagent mixing.

VI. Frequently Asked Questions (FAQ)

Q1: Does the 1200-type wet disc mill have strict requirements for feed particle size?

A1: Yes. The ideal feed particle size is usually between 0-10mm, and it needs to be evenly distributed. This requires a reliable crushing and screening system at the front end. Appropriate feed particle size is a prerequisite for high output, low consumption, and stable operation of the mill.

Q2: What are the replacement cycle and cost of wear parts when processing high-hardness gold ore?

A2: We use customized high-wear-resistant materials. Under standard quartz vein type gold ore conditions (Mohs hardness approximately 7), the service life of the core grinding rollers and grinding disc liners can usually reach 6000-8000 operating hours. Replacement costs are part of equipment operation, but due to the high operating rate and high recovery rate benefits, the overall cost per ton of ore is far lower than that of inefficient traditional equipment.

Q3: Does the equipment support remote monitoring and intelligent diagnostics?

A3: Yes, it fully supports these features. Our new generation 1200 series wet grinding mill can be equipped with an IoT gateway to upload operating data to the cloud or the customer's central control system. Our engineers can perform remote status monitoring, fault prediction analysis, and provide preventive maintenance suggestions, significantly improving management efficiency.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.