What Is The Wet Ball Mill Method?

As a mineral processing equipment manufacturer with 20 years of experience, we deeply understand the fundamental role of grinding in the entire mineral processing flow. Wet ball milling, as one of the most classic and widely used mineral grinding technologies, directly impacts the success or failure of subsequent separation operations in terms of efficiency and stability. This article will provide an in-depth analysis of wet ball milling, giving you a comprehensive understanding of its principles, advantages, and practical applications.

| Key Words | What Is The Wet Ball Mill Method? |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

In-depth Analysis of Wet Ball Milling

Wet ball milling, as the name suggests, refers to a process in which water (or other liquids) is added as a grinding medium, and the minerals to be ground are ground together within a rotating ball mill cylinder. Its core mechanism utilizes the centrifugal force generated by the rotation of the cylinder to lift the internally loaded steel balls (or other grinding media) to a certain height before they fall, thereby impacting, grinding, and abrading the material. Carried by the water flow, this achieves particle size reduction and mineral liberation.

Overview of Wet Ball Milling

Basic Working Principle

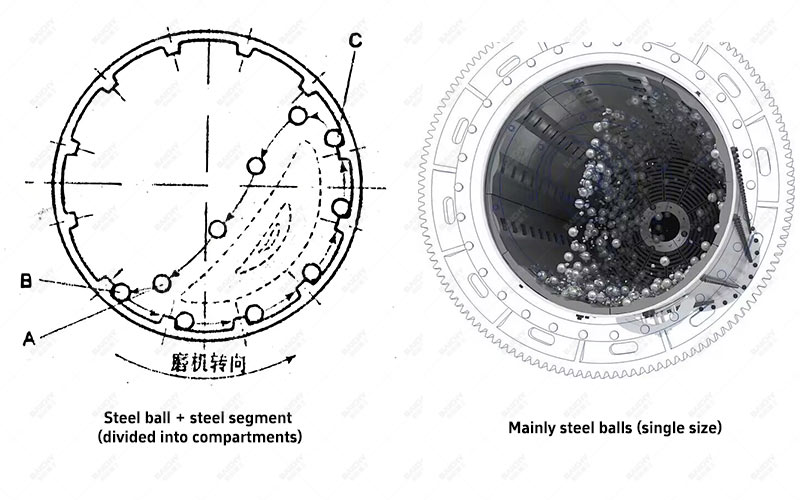

In a wet ball mill, material and water are continuously added from the feed end at a specific ratio (usually called slurry concentration). The mill cylinder rotates uniformly under the drive of a motor, and the grinding media (steel balls, steel rods, or ceramic balls, etc.) inside are lifted by friction and centrifugal force. After reaching a certain height, the media fall in a waterfall-like manner due to gravity, generating a strong impact and grinding effect on the material below. The finely ground particles flow out with the water through the discharge end. A classifying device (such as a spiral classifier or hydrocyclone) is usually also included to form a closed-loop circulation, ensuring that the product particle size is within specifications.

Working structure of ball mill

Core Components

A complete wet ball mill system mainly includes:

• Ball Mill Body: Includes the cylinder, liners, end covers, large gear, small gear shaft, etc.

• Feeding System: Feeder and chute, responsible for uniformly and continuously feeding material and water.

• Transmission System: Motor, reducer, and large and small gears provide rotational power.

• Discharge and Classification System: Discharges the finely ground slurry and classifies it by particle size; coarse particles are returned for regrinding.

• Lubrication and Control System: Ensures stable equipment operation.

Core Advantages of Wet Ball Milling

Compared to dry ball milling, wet ball milling has significant advantages in mineral processing, which is why it is widely used:

1. High grinding efficiency and large production capacity: The presence of water removes heat, reduces material adhesion, and prevents over-grinding and clogging, making grinding more efficient. The output per unit energy consumption is usually higher than that of dry grinding.

2. Uniform product particle size and less over-grinding: The water flow can promptly remove fine particles that have reached the required particle size, reducing the buffering effect of fine powder and energy waste, resulting in a more concentrated product particle size distribution.

3. Extremely low dust pollution and a friendly working environment: The entire process is carried out in slurry form, fundamentally eliminating dust emissions, improving the working environment, and meeting modern environmental protection requirements.

4. Applicable to subsequent wet separation processes: Most mineral processing methods (such as flotation, magnetic separation, and gravity separation) require slurry processing. Wet grinding directly produces slurry, allowing for seamless integration with subsequent operations and a smooth process flow.

5. Relatively low operating noise and good equipment sealing.

2.4x8m Ball mill shipped

Real-world application case

Among our many clients, the case of a large lead-zinc mine beneficiation plant in Hunan is quite representative. The plant originally used a single-stage coarse grinding mill, but the product particle size did not meet the optimal liberation requirements, affecting the flotation recovery rate.

• Problem: The raw ore had a fine particle size distribution; the -200 mesh content in the single-stage grinding product was only 65%, indicating insufficient liberation of valuable minerals.

• Solution: We designed and provided a modification solution of "single-stage closed-circuit wet ball mill + hydrocyclone classification". An energy-efficient wet grate ball mill was adopted, and the steel ball gradation and grinding concentration were optimized.

• Results: After the upgrade, the -200 mesh content in the ground product stabilized above 85%, and the liberation degree of lead and zinc minerals was significantly improved, resulting in an increase in the recovery rate of subsequent flotation operations by approximately 3% and 2.5%, respectively, leading to a significant increase in annual economic benefits.

Related Equipment Recommendations

Choosing reliable wet ball mill equipment is crucial. Our company offers a full range of wet ball mills, with core products including:

• Energy-saving overflow ball mill: Suitable for fine grinding or the second stage of a two-stage grinding process, producing a finer particle size.

• High-efficiency grate ball mill: Suitable for single-stage coarse grinding, with fast discharge speed, less over-grinding, and larger throughput.

• Cone ball mill: Large processing capacity, suitable for medium and large-sized concentrators.

• Customized Services: We offer a one-stop solution, from equipment selection and steel ball gradation recommendations to system optimization, tailored to the specific ore properties (hardness, particle size, density) and production capacity requirements of our clients.

Frequently Asked Questions (FAQ)

1. How to choose between wet and dry ball mills?

It mainly depends on the process requirements and material characteristics. Wet ball mills are suitable for the beneficiation of most metallic and non-metallic ores, especially in applications where subsequent wet separation is required and dust control is necessary. Dry ball mills are suitable for water-scarce areas, materials that are sensitive to water (such as cement and certain chemical products), or situations where the product needs to be shipped in dry powder form.

2. What are the key operating parameters of a wet ball mill?

There are three main parameters: grinding concentration (the percentage of solids by weight in the slurry), mill feed particle size and velocity, and steel ball filling rate and gradation. These parameters need to be optimized and adjusted based on ore grindability tests to achieve the best grinding effect.

3. How to reduce the energy consumption of wet ball mills?

This can be approached from multiple dimensions: select high-efficiency and energy-saving ball mills (such as using rolling bearings instead of sliding bearings); optimize the steel ball gradation and liner shape; precisely control the grinding concentration and circulating load; and use frequency converters to control the mill speed to adapt to different throughput requirements. Our equipment incorporates multiple energy-saving technologies from the initial design stage.