Dry Grinding Vs. Wet Ball Mill Grinding

Topic Overview: Two Core Paths in Grinding Processes

In mineral processing, building materials, metallurgy, and chemical industries, material grinding is a crucial process. As a mineral processing equipment manufacturer with 20 years of experience, we understand that choosing the right grinding method has a decisive impact on production efficiency, energy consumption, and final product quality. Dry grinding and wet grinding are two basic operating modes of ball mills. They are not simply technological substitutions, but rather targeted solutions for different material characteristics and production needs. This article will delve into the principles, advantages, disadvantages, and application scenarios of these two ball mill grinding methods to help you make informed decisions.

| Key Words | Dry Grinding Vs. Wet Ball Mill Grinding |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

In-Depth Analysis: Working Principles and Core Differences

Dry Ball Mill Grinding

Dry grinding, as the name suggests, is conducted in a completely dry environment or one containing only trace amounts of moisture. The material is fed into the mill cylinder by a feeding device and is pulverized by the impact and grinding action of steel balls or grinding media. Air is introduced during the grinding process; qualified fine powder is carried out by the airflow, while coarse particles continue to be ground. This system is usually equipped with grading and dust collection equipment.

Wet Ball Mill Grinding

Wet grinding involves adding water or other liquid media during the grinding process. The material and water flow together into the mill, forming a slurry. The grinding media, buffered and carried by the water, crush and grind the material. The product is discharged as a slurry through the discharge end, and is typically followed by classification (such as spiral classifiers or hydrocyclones) or separation operations.

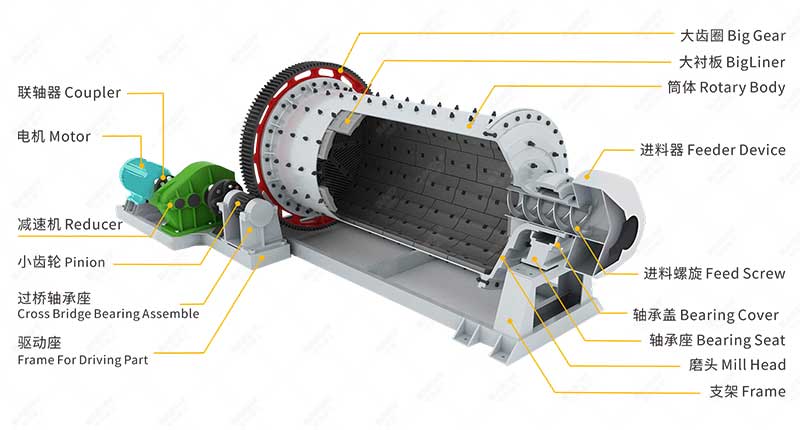

Ball mill structure diagram

Advantages Comparison: Adapting to Local Conditions, Each Showing Its Strengths

Dry Ball Mill Advantages

1. Product Drying: The final product is dry powder, requiring no subsequent dehydration and drying, suitable for water-scarce areas or applications with strict moisture requirements (such as cement, certain non-metallic minerals).

2. Investment and Operating Costs: Typically, no concentration, filtration, or other dehydration equipment is needed; the system is relatively simple, and investment may be lower.

3. Environmental Adaptability: Modern dry grinding systems are equipped with high-efficiency dust collectors, effectively controlling dust and meeting environmental requirements.

Advantages of Wet Ball Mills

1. High Grinding Efficiency: The liquid medium reduces material adhesion, minimizing over-grinding, and facilitates smoother conveying and classification. Overall energy efficiency is generally superior to dry grinding.

2. No Dust Pollution: The entire process is wet, completely eliminating dust and creating a superior working environment.

3. Suitable for Subsequent Wet Processes: If the subsequent process is wet mineral processing (flotation, magnetic separation) or wet chemical processes, wet grinding can be directly integrated, ensuring a seamless process.

Ball mill customer site

Practical Application Case Reference

• Case 1 (Dry Grinding): A large cement plant in North China uses limestone and clay as raw materials. Because its final product is cement clinker grinding, and local water resources are relatively scarce, it selected our Ф4.2×13m large dry ball mill, combined with a high-efficiency classifier and baghouse dust collector. The system operates stably, the product fineness meets standards, and environmental benefits are significant.

• Case Study 2 (Wet Grinding): A copper ore beneficiation plant in Africa required its raw ore to be ground to -200 mesh (75%) before flotation. Our company configured a closed-circuit grinding system consisting of a Ф3.6×6.0m wet grate ball mill and a hydrocyclone. This configuration offers high grinding efficiency, good slurry flowability, perfectly matching the requirements of flotation operations, and significantly improving copper recovery.

Equipment Selection Recommendations for Manufacturers

The choice between dry and wet grinding primarily depends on the material properties and process requirements.

• Recommended Dry Grinding Scenarios: Materials with a certain degree of moisture that may cause adhesion, products requiring dryness, subsequent dry processing, or in severely water-scarce regions. Suitable for cement, silicate products, refractory materials, glass ceramics, and some non-metallic minerals.

• Recommended Wet Grinding Scenarios: Pre-concentration grinding of most metallic ores (iron, copper, gold, lead, zinc, etc.), materials with high moisture content, or requiring extremely fine grinding (above -325 mesh), and subsequent hydrometallurgical or chemical processes. Wet grinding typically performs better in preventing over-grinding and improving monomer liberation.

As an experienced manufacturer, we can provide customized ball mill grinding solutions and equipment based on your mineral sample test reports.

Frequently Asked Questions (FAQ)

1. Can a dry ball mill be converted to a wet ball mill, or vice versa?

Direct conversion is not recommended. There are fundamental differences in structural details (such as discharge end, liner design), sealing methods, and supporting systems. Forced conversion may result in equipment damage, inefficiency, or serious leaks. If process changes are required, consult the manufacturer for a completely new design.

2. Does wet grinding consume a lot of water? Is there a water recycling system?

Modern wet grinding processes place great emphasis on water resource recycling. After grinding, the slurry is classified, and most of the water is returned to the mill for reuse through a water return system, making overall water consumption controllable. Well-designed concentrators can achieve high water return rates.

3. Which method is more economical in terms of investment costs?

It's not a simple matter. While dry grinding may eliminate the need for a dehydration system, its requirements for dust collection and explosion-proof features could increase costs. Wet grinding, although requiring a dehydration process, may reduce the overall cost per unit of energy consumption due to its higher grinding efficiency. A comprehensive calculation of the entire mining-grinding-benefiting process is necessary to arrive at an economically viable conclusion.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.