Ball Mill

Introduction

In the field of mineral processing, grinding is a crucial step that determines the quality and recovery rate of the final product. As a professional manufacturer of mobile crushing equipment for mines, we understand that after coarse crushing, fine grinding is equally important. This article will delve into the core applications of wet ball milling technology in processing metal ores and non-metallic minerals, explaining why it is an indispensable process choice for many processing plants.

Overview of Wet Ball Milling Technology

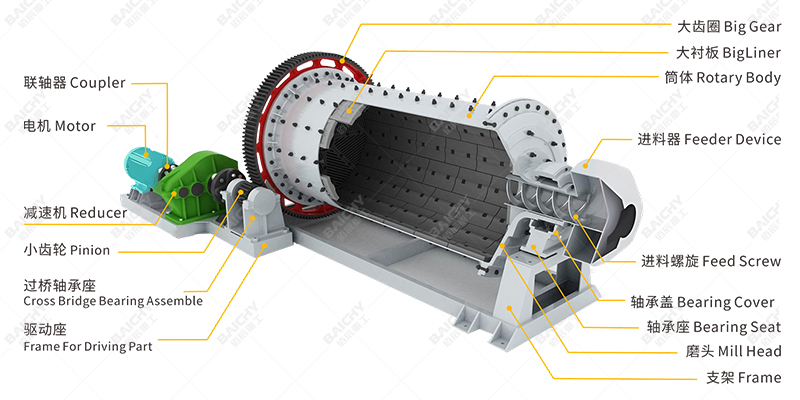

Wet ball milling, as the name suggests, is a grinding method that uses water or other liquids as a medium during the grinding process. Compared to dry ball milling, the material is mixed with water in the mill, forming a slurry, which is then refined under the impact and grinding action of steel balls or ceramic balls. This process is particularly suitable for mineral processing that requires subsequent wet metallurgical processes such as flotation and leaching, and is a core equipment for achieving mineral liberation and improving separation indicators.

Analysis of the Core Advantages of Wet Ball Milling

Why is wet ball milling so popular in metal and non-metallic mineral processing? Its advantages are comprehensive and decisive.

High grinding efficiency, less over-grinding

The presence of a water medium acts as a buffer and lubricant, effectively carrying away fine particles, reducing "over-grinding," and preventing fine powder from adhering to the grinding balls and liners, thus maintaining high grinding efficiency and achieving a more uniform particle size distribution.

Dust-free and environmentally friendly, excellent working environment

The entire process takes place in a liquid state, fundamentally eliminating dust pollution. This not only meets increasingly stringent environmental requirements but also greatly improves the working environment for on-site operators and reduces occupational health risks.

Suitable for continuous operation and complex processes

Wet ball milling can easily be integrated with classification equipment (such as spiral classifiers and hydrocyclones) to form a closed-loop system for continuous automated production. The ground slurry can be directly pumped to subsequent flotation, magnetic separation, and other operations, ensuring smooth process, and is particularly suitable for processing metal ores that require multi-stage separation.

| Key Words |

1 t/h 900x1800 Small Ball Mill |

| Product Model |

Wet Ball Mill |

| Feed Size |

≤25mm |

| Motor Power |

18.5-4500kw |

| Capacity |

0.65-615t/h |

| Core Functions |

Grinding precision and particle size controllability |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Application Scenarios and Case Studies

Wet ball milling has extremely wide applications, covering almost all important mineral types.

Grinding of Metal Ores

For metal ores such as copper ore, gold ore, iron ore, and lead-zinc ore, wet ball milling is the standard preparation process before flotation. It grinds the ore to a fineness suitable for flotation (usually 70%-90% passing -200 mesh), allowing for sufficient liberation of valuable minerals from gangue. A typical example is a large copper mine concentrator that uses a closed-circuit grinding system consisting of wet ball mills and hydrocyclones to grind the raw ore to 85% passing -200 mesh, providing ideal feed conditions for subsequent flotation and ultimately increasing copper recovery by approximately 5%.

Fine Processing of Non-metallic Minerals

In the field of non-metallic minerals, such as feldspar, quartz sand, kaolin, and barite, wet ball milling is a key step in achieving ultra-fine grinding and high-purity purification. For example, in the preparation of high-grade ceramic raw materials, wet ball milling not only grinds the material to extremely fine particles (e.g., -2 microns) but also effectively homogenizes the composition and removes some impurities.

Equipment Linkage and System Recommendations

As a manufacturer of mobile crushing equipment, we emphasize system synergy. Using our mobile jaw crushers and mobile cone crushers for primary and secondary crushing at the front end produces uniformly sized feed, which can significantly improve the feeding efficiency and overall capacity of the downstream fixed or semi-mobile wet ball mills. This "mobile crushing + fixed/semi-mobile grinding" combination is particularly suitable for projects with dispersed mining areas or those requiring preliminary on-site testing, offering both flexibility and stability.

Mobile Jaw Crusher

Mobile Cone Crusher

Frequently Asked Questions (FAQ)

Q1: How to choose between wet ball milling and dry ball milling?

A1: The choice depends on the mineral properties, subsequent processes, and environmental requirements. If the subsequent process is wet beneficiation (such as flotation), or if the mineral itself is prone to dust generation, is sticky, or has extremely high environmental requirements, wet ball milling is the better choice. If the subsequent process is dry beneficiation (such as dry magnetic separation) or in areas with extremely limited water resources, dry milling can be considered.

Q2: Is the energy consumption of wet ball milling very high?

A2: Grinding is inherently a high-energy-consuming operation. However, thanks to higher grinding efficiency and smoother material flow, wet ball milling systems are generally more energy-efficient in achieving the same fineness. Energy saving focuses on optimizing the steel ball ratio, using wear-resistant lining materials, and equipping with efficient classification systems.

Q3: How to control the output particle size of wet ball milling?

A3: This is mainly controlled by adjusting the material concentration in the mill, the size and ratio of grinding balls, and the classification equipment in the closed-loop system (such as the pressure and underflow opening size of the hydrocyclone). This is a system optimization process that requires comprehensive settings based on ore hardness and feed particle size.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!