Vertical Roller Mill

Overview: The Core of High-End Powder Processing Beyond Cement

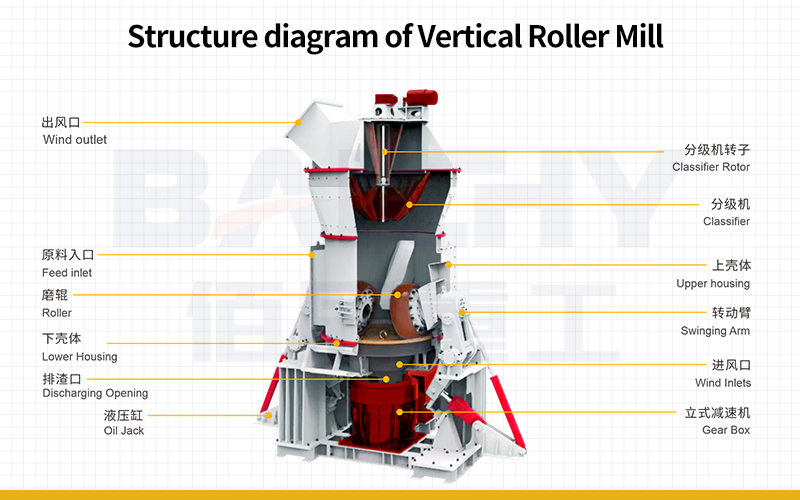

As a professional manufacturer of mobile mining crushing equipment, our service areas have long surpassed traditional building materials. Today, deep processing and high-value utilization of minerals have become the mainstream trend, and the vertical ultrafine grinding mill (typically based on vertical roller mill SRM technology) is a core equipment in this trend. It is specifically designed for producing fine and ultrafine powders with high specific surface area and strict particle size distribution, and is widely used in high-end fields such as non-metallic minerals, industrial minerals, and solid waste recycling, transforming ordinary crushed ore into high-value fine products.

In-Depth Technical Analysis: The Value Leap Chain from Coarse Crushing to Ultrafine Grinding

The vertical ultrafine grinding mill is a high-end evolution of vertical roller mill technology. Its core lies in the precise and enhanced modification of the traditional SRM's classifier system, grinding roller pressure control system, and airflow system. It inherits the material bed grinding principle of SRM, crushing material particles through ultra-high pressure (grinding roller pressure can reach several times that of ordinary raw material mills), resulting in lower energy consumption and a more concentrated product particle size distribution. High-speed vortex classifiers or high-efficiency dynamic classifiers can accurately classify products from 325 mesh to 2500 mesh or even finer, meeting the stringent requirements of industries such as chemicals, coatings, fillers, and electronic materials.

Outstanding Advantages of the Vertical Ultrafine Grinding Mill (SRM Mill)

Compared with traditional air mills, ball mills, and Raymond mills, the vertical ultrafine grinding mill demonstrates revolutionary advantages in the field of ultrafine powder production.

Ultra-High Grinding Efficiency and Low Energy Consumption

Despite producing ultrafine powders, its material bed grinding principle still offers significant energy consumption advantages. At the same fineness, its system power consumption can be reduced by 20%-40% compared to traditional tube mills or some air mills, especially in large-scale, continuous ultrafine powder production, resulting in millions of dollars in energy savings.

Precisely Controllable and Concentrated Product Particle Size Distribution

By adjusting parameters such as classifier speed and system airflow, the finished product fineness (D97) can be precisely controlled online. Its product particle size distribution curve is steep, with a narrow particle size distribution range, avoiding the generation of excessive coarse or fine particles. This is crucial for improving the performance of downstream products, especially for high-end fillers and coatings.

Integrated Drying Function, Wide Applicability

Like the basic SRM, it integrates a drying function and can directly process materials with a moisture content of 6%-8% (higher levels are achievable with a high-temperature heat source). It is particularly suitable for the ultrafine processing of moisture-containing non-metallic minerals (such as kaolin and bentonite) and industrial by-products (such as steel slag and blast furnace slag), eliminating the need for pre-drying and simplifying the process.

Low Wear, Controllable Maintenance Costs

Although the material hardness is high, due to the material bed extrusion crushing method, metal wear is generally lower than that of impact crushers. Wear-resistant parts (such as grinding roller liners and grinding disc liners) adopt a modular design, resulting in a long service life and relatively convenient replacement, making the overall maintenance costs competitive.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Application Case: The Transformation from Limestone to High-End Calcium Carbonate

We provided a complete "crushing-ultrafine grinding-modification" solution for a large calcium carbonate deep processing enterprise in East China. The front-end uses European-style jaw crushers and hydraulic cone crushers to crush the calcite ore to clean small particles of 0-10mm.

Core Deep Processing Stage: The crushed material is fed into a large vertical ultrafine grinding mill. This mill is equipped with a high-efficiency turbine classifier, successfully producing three main products: 800 mesh (D97=19μm), 1250 mesh (D97=10μm), and 2000 mesh (D97=6.5μm) heavy calcium carbonate powder. The system has stable output, and the power consumption for the 1250 mesh product is only 65 kWh/t. The product particle size distribution fully meets the requirements of high-end plastic masterbatches and coatings, laying a technical foundation for the enterprise to successfully enter the high-value-added market.

Recommended Supporting Equipment and Processes

High-Efficiency Fine Crusher/Sand Making Machine: In the final crushing stage before entering the ultrafine grinding mill, pre-treating the material to 3-5mm or even finer can greatly improve the capacity of the ultrafine grinding mill and reduce the power consumption per unit output.

Fine Classification and Collection System: Includes a high-efficiency turbine classifier and a multi-stage high-efficiency cyclone separator with a nano-grade coated filter bag dust collector, ensuring fine classification and high collection rate of the finished product. This is a core auxiliary equipment for the production of ultrafine powders.

Precision Feeding and Metering System: Uses a loss-in-weight feeder or a precision belt scale to ensure uniform, stable, and accurate feeding, which is a prerequisite for maintaining a stable material bed in the mill and ensuring stable product quality.

Surface Modification Production Line (Optional): Provides online or offline coating and modification of ultrafine powders to improve their compatibility and performance in plastics and rubber, realizing an integrated "crushing-grinding-modification" turnkey project.

High-efficiency Fine Crusher

VSI Sand Making Machine

FAQ Frequently Asked Questions

Q1: What types of minerals can the vertical ultrafine grinding mill process? What fineness can it achieve?

A1: It is suitable for various non-metallic minerals and industrial materials with a Mohs hardness of less than 7, such as limestone, calcite, barite, kaolin, bentonite, gypsum, slag, steel slag, etc. Through optimized configuration, the fineness of the finished product can be flexibly adjusted within the range of D97: 5μm to 45μm (325 mesh - 2500 mesh). For materials with higher hardness, the economic feasibility of wear needs to be evaluated.

Q2: Why is the selection of front-end crushing equipment so important for the production of ultrafine powders?

A2: "More crushing, less grinding, using crushing instead of grinding" is a basic energy-saving principle in powder engineering. High-efficiency fine crushing equipment at the front end can reduce the particle size of the material entering the mill from the traditional 10-20mm to 3-5mm. This directly reduces the grinding pressure of the vertical ultrafine grinding mill, significantly increases the hourly output (can increase by 20%-50%), and significantly reduces the power consumption per ton of product. As crushing experts, we can provide the optimal front-end crushing and shaping solution for ultrafine powder production lines.

Q3: Compared with traditional air jet mills, what are the differences in investment and operating costs of the vertical ultrafine grinding mill?

A3: In terms of initial investment, for medium and large-scale capacities (more than 5 tons per hour), the vertical ultrafine grinding mill is usually lower than air jet mills of the same capacity. In terms of operating costs, its advantages are even more significant: 1) Low power consumption: As mentioned earlier, it offers significant energy savings; 2) Controllable wear costs: The cost of its wear parts is usually lower than that of the nozzles, liners, and other high-wear parts of air jet mills; 3) High degree of automation: It is more suitable for continuous and large-scale production. Therefore, for large-volume production of ultra-fine powders with medium fineness, the vertical ultra-fine grinding mill is a more economical choice.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!