Wet Ball Mill Industrial Grinding Mill Superior for Silica

In the fields of mineral processing and deep material processing, silica (quartz sand, silica powder, etc.) is an important industrial raw material, and its fineness and purity directly determine the value of the final product. As a mineral processing equipment manufacturer with 20 years of experience, we understand that choosing the right grinding equipment is key to improving quality and efficiency. Among many types of equipment, the wet ball mill is undoubtedly a long-standing core tool in the wet grinding process of silica.

| Key Words | Wet Ball Mill Industrial Grinding Mill Superior for Silica |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

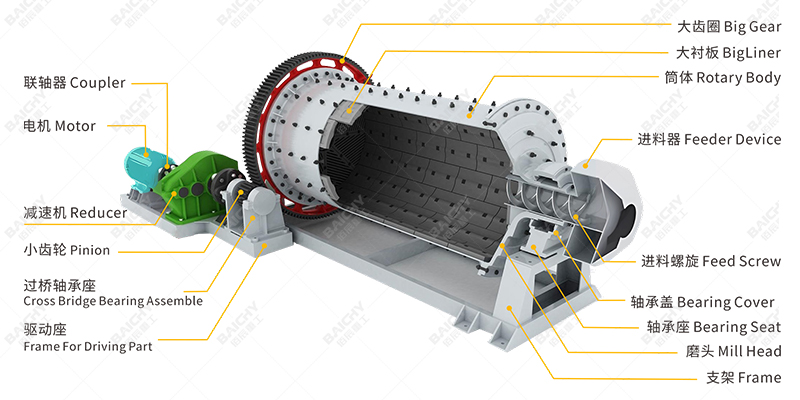

Wet Ball Mill Overview: Working Principle and Structure

A wet ball mill is an industrial grinding mill that loads a certain proportion of grinding media (such as steel balls or ceramic balls) and the material to be ground into a cylinder, and adds water or other liquids for wet grinding. Its core working principle is: when the cylinder rotates under the drive of a motor, the grinding media are lifted to a certain height under the action of friction and centrifugal force and then thrown down, generating impact, grinding, and shearing effects on the silica material inside the cylinder, thereby achieving ultrafine pulverization of the material.

Ball mill structure

Main structures include:

• Drive system: Provides power.

• Rotary Cylinder: The core grinding chamber, lined with wear-resistant plates.

• Feed/Discharge Device: Enables continuous feeding and slurry discharge.

• Grinding Media: The direct implementers of the grinding action.

Why is a wet ball mill the ideal choice for grinding silica?

Compared to traditional dry grinding, wet ball mills exhibit unparalleled systemic advantages in processing silica, which is a key reason why they have become the industry standard.

1. Superior Grinding Efficiency and Finer Particle Size

The presence of water acts as both a grinding aid and a dispersant. It promptly removes fine particles, preventing over-grinding and agglomeration, while simultaneously promoting crack propagation, concentrating energy on the newly broken surface, thus achieving higher grinding efficiency and a more uniform, finer final product (typically reaching tens or even several micrometers).

2. Effective Dust Control, Environmentally Friendly and Safe

Silica dust (especially crystalline silica dust) is a serious occupational health hazard, potentially leading to silicosis. Wet milling fundamentally eliminates dust, creating a clean and safe production environment that fully complies with modern stringent environmental and safety standards.

3. Lower Heat Effect and Higher Purity

The heat generated during grinding is absorbed by water, preventing localized high temperatures. This is crucial for protecting equipment and preventing changes in material properties. Simultaneously, wet milling facilitates simultaneous purification during grinding (e.g., through classification and impurity removal), directly yielding high-purity silica slurry.

4. Stable Operation and Low Noise

The slurry provides a buffering effect on the steel balls and liners, resulting in smoother equipment operation and significantly lower mechanical noise compared to dry ball mills. It also extends the service life of wear parts.

Ball mill customer site

Successful Application Case: From Quartz Sand to High-Purity Silica Powder

We provided a complete wet milling solution for a client in East China specializing in the production of high-whiteness silica powder for coatings. The client previously used a Raymond mill, resulting in a wide particle size distribution, unstable whiteness, and severe dust pollution in the workshop.

• Challenge: Improve product fineness (target d97 < 15μm), stabilize whiteness > 92%, and achieve clean production.

• Solution: We recommended and installed a medium-sized energy-efficient wet ball mill, equipped with quartz liners and ceramic ball media, employing a closed-loop circulation grinding-classification process.

• Results: The product fully met and partially exceeded the fineness and whiteness targets; no visible dust was generated throughout the production process; overall energy consumption was reduced by approximately 18%; product competitiveness was significantly enhanced, successfully penetrating the high-end coatings supply chain.

Our Wet Ball Mill Product Line Recommendation

Based on 20 years of technological accumulation, we offer a full range of wet ball mills to meet the grinding needs of silica of different scales and purities:

• Energy-Saving Wet Ball Mill: Utilizes rolling bearings instead of sliding bearings, resulting in lower starting resistance and energy savings of up to 30%, suitable for large-scale continuous production.

• High-purity ceramic-lined wet ball mill: The inner cylinder is lined with high-alumina ceramic or silica plates and fitted with ceramic balls to minimize iron contamination. Specifically designed for high-purity, ultra-white silica.

• Small laboratory wet ball mill: Suitable for process development and small-batch production of high-value-added materials.

Frequently Asked Questions (FAQ)

1. How to choose grinding media for grinding silica in a wet ball mill?

This depends on the required product purity. For ordinary ceramic and glass raw materials, high-chromium steel balls offer good cost-effectiveness; for high-end applications requiring high whiteness and low iron impurities (such as electronic-grade silicon micropowder and high-end coatings), ceramic balls (alumina, zirconia, or silica balls) and appropriate liners must be used.

2. How to process the ground slurry? What equipment is needed afterward?

The slurry from wet milling typically requires grading equipment (such as hydrocyclones and vibrating screens) to control the final particle size, and then is processed by dewatering equipment (such as filter presses, centrifuges, and dryers) to obtain powder or be supplied directly as slurry. We can provide integrated solutions from grinding to dewatering.

3. Compared to dry ball mills or vertical mills, are wet ball mills more energy-efficient?

Comparing only the main unit, wet ball mills may not have an advantage. However, considering the overall energy consumption of the process system, wet milling is often more economical. It eliminates the high-energy-consuming steps required by dry processes, such as hot air drying and fine dust removal. When pursuing ultrafine powders, the overall energy consumption and cost of wet milling are usually lower.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.