Wet Ball Mill Machine: Exploring Its Function and Applications

In industries such as mineral processing, building materials, and chemicals, material crushing is a crucial step. As a core grinding equipment, the wet ball mill dominates in mineral processing plants and industrial production lines worldwide due to its unique working principle and superior performance. As a mineral processing equipment manufacturer with 20 years of experience, we will delve into all aspects of this "grinding mainstay."

| Key Words | Wet Ball Mill Machine: Exploring Its Function and Applications |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

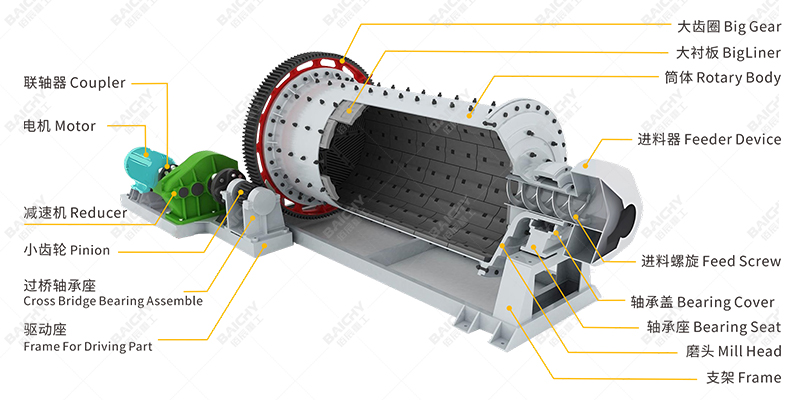

Wet Ball Mill Overview

A wet ball mill is a key piece of equipment for grinding materials in an aqueous medium. Its core structure includes a large, horizontally placed rotating cylinder. The cylinder is loaded with a specific proportion of grinding media (usually steel balls) and the material to be ground, along with an appropriate amount of water. When the cylinder rotates under the drive of a motor, the steel balls and material are lifted to a certain height under the combined action of centrifugal force and friction, and then fall or slide down. Through impact, grinding, and shearing, the material is crushed to the required fineness, forming a slurry that is discharged.

Ball mill structure diagram

Why Choose a Wet Ball Mill? Analysis of its core advantages

Compared to dry ball milling, wet ball milling exhibits significant advantages in several aspects, which is the fundamental reason for its widespread application.

Higher grinding efficiency and finer particle size

The presence of water as a medium acts as a "lubricant" and "carryer." It not only effectively reduces material adhesion, preventing over-grinding and acting as a "buffer," but also promptly carries fine particles that have met the fineness requirements out of the grinding zone, thereby significantly improving grinding efficiency and making it easier to obtain finer product particle sizes, particularly suitable for subsequent flotation and leaching processes.

Superior working environment and lower overall cost

The wet grinding process generates almost no dust, greatly improving the working environment and meeting modern industrial environmental and occupational health standards. Simultaneously, because water lowers material temperature and reduces wear, the equipment operates more smoothly, helping to extend the service life of vulnerable parts such as liners and steel balls, thus reducing overall operating costs.

Suitable for a variety of materials and processes

Whether it's metallic minerals (such as iron, copper, gold, lead, and zinc), non-metallic minerals (such as quartz, feldspar, and fluorite), or industrial by-products, as long as the material allows contact with water, the wet ball mill can process it efficiently. Its product (slurry) can directly flow into the next wet process, ensuring a smooth workflow.

Real-world application case studies

We have provided professional wet ball mill solutions for numerous projects both domestically and internationally.

Case Study 1: A large iron ore beneficiation plant

This plant uses our Φ3.6x6.0m wet ball mill to process raw ore. Through two-stage grinding, the ore is ground to a fineness of -200 mesh (85%), providing ideal conditions for subsequent magnetic separation. The hourly throughput is consistently above 180 tons, and the concentrate grade and recovery rate both meet design specifications.

Case Study 2: A Copper-Molybdenum Mine Production Line

Addressing the high hardness and uneven particle size distribution of copper-molybdenum ore, we designed a wet ball mill unit equipped with high-performance corrugated liners and a classification system. This solution achieved an energy consumption reduction of approximately 15% while ensuring sufficient liberation of molybdenum ore, significantly improving the recovery rate of valuable metals.

Ball mill customer site

Our Equipment and Services Recommendations

Based on 20 years of technological accumulation, we offer a full range of wet ball mills, from experimental models to large-scale industrial equipment (diameters up to 4.5 meters and above). We not only provide equipment but also customized solutions:

• High-efficiency and energy-saving ball mills: Optimized transmission design reduces starting load and saves energy.

• Customized wear-resistant parts: We offer liners and steel balls made of various materials such as high-chromium alloy and rubber to adapt to different grinding conditions.

• Intelligent control system: Optional automatic feeding, concentration, and particle size monitoring systems enable intelligent and stable production.

• Full lifecycle service: From site survey, process design, installation and commissioning to after-sales support, we provide comprehensive support.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between wet and dry ball mills? How should one choose?

A1: The core difference lies in the grinding media (water for wet mills, air for dry mills). The choice depends on the material characteristics, subsequent processes, and environmental requirements. If the material does not change its properties upon contact with water, and the subsequent process is wet (such as flotation), or if dust control requirements are extremely high, a wet ball mill is usually a better choice. If the material is sensitive to water, or if a dry powder product is required, a dry mill should be chosen.

Q2: What are the key operating parameters of a wet ball mill? How can they be optimized?

A2: Key parameters include: grinding concentration (solid-liquid ratio), steel ball filling rate and ratio, cylinder rotation speed, and feed particle size and velocity. Optimization requires adjustments through experimentation and practice, with the goal of finding the optimal balance between efficiency, energy consumption, and product fineness. We can provide professional parameter adjustment services for our clients.

Q3: In which parts of the equipment does wear mainly occur? How can maintenance costs be reduced?

A3: The main wear parts are the cylinder liner and the abrasive media (steel balls). The key to reducing maintenance costs is to: select high-quality wear-resistant materials that match the hardness and corrosiveness of the material; maintain a reasonable steel ball replenishment schedule; and regularly check and tighten the liner bolts to prevent abnormal wear caused by loosening.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.