Vertical Grinding Mill Customer Site

Overview: The Core Grinding Equipment of the Cement Industry

As a professional manufacturer of mobile mining crushing equipment, we understand that after the limestone, clay, and other raw materials extracted from the mine are processed by our crushing system, the next crucial stage is grinding. In cement production, the vertical roller mill is the key equipment that performs this core task, mainly used in the two major processes of raw material grinding and cement grinding. It transforms the crushed lump materials into extremely fine, chemically active powders, serving as an indispensable link between raw material pretreatment and high-temperature calcination.

In-depth Analysis: The Role of Vertical Roller Mills in Cement Production

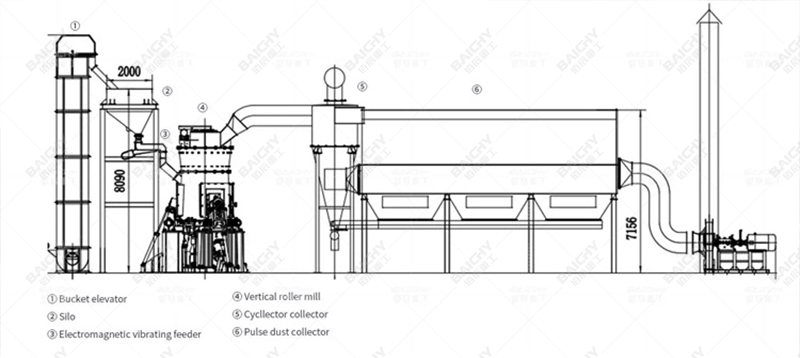

The vertical roller mill (referred to as vertical mill) has completely revolutionized the grinding method of traditional ball mills with its unique working principle. It feeds the crushed raw materials into the center of the grinding table through a sealed feeding device, where they are dispersed to the periphery of the grinding table by centrifugal force. The grinding rollers, under the action of a hydraulic system, exert enormous pressure on the material bed, crushing the material. At the same time, hot air introduced from the bottom dries the material and blows the qualified fine powder into the classifier for separation.

Core Advantages of Vertical Roller Mills in Cement Production

Compared with traditional tube mill (ball mill) systems, vertical mills demonstrate overwhelming advantages in modern cement plants.

Excellent Energy Saving Effect

This is the most prominent advantage of vertical mills. Using the principle of material bed grinding, energy is directly applied to the material, resulting in extremely low energy loss. Its power consumption is typically 30% to 50% lower than traditional ball mill systems. For a cement production line with a daily output of 5000 tons, the raw material grinding process alone can save millions of kilowatt-hours of electricity annually, resulting in significant economic benefits.

Powerful Integrated Drying and Grinding Capability

The vertical mill integrates grinding, drying, and classification. A large amount of hot air (up to over 400°C) is introduced internally, allowing it to simultaneously process raw materials with a moisture content as high as 15%-20% (such as wet clay or slag). This eliminates the need for specialized drying of materials in the front-end crushing system, simplifying the process and making it particularly suitable for direct integration with our mobile crushing plants at mine sites, enabling immediate raw material pre-processing.

Simple System, Small Footprint

The vertical mill integrates multiple functions into a single main unit, eliminating the need for external drying and classifier systems. The process is compact, requiring less plant building area and space, resulting in lower infrastructure investment.

Low Noise and Environmentally Friendly

The equipment operates smoothly, with noise levels typically below 85 decibels. The entire system is enclosed and operates under negative pressure, easily achieving dust emission concentrations below 20 mg/Nm³, far exceeding national environmental standards.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Application Case: A Continuous Production Line from Mobile Crushing to Vertical Mill Grinding

A cement raw material base project we participated in in Southeast Asia perfectly demonstrates the efficient linkage from "mobile crushing" to "vertical mill grinding." The client used our large mobile jaw crusher and mobile cone crusher for secondary crushing of limestone at the quarry, crushing the material to 0-40mm. The crushed material was then directly transported via a long belt conveyor to the pre-homogenization stockpile at the raw material blending station.

Grinding stage: The homogenized raw materials were fed into a domestically produced large raw material vertical roller mill. This vertical mill successfully processed mixed raw materials containing a certain amount of moisture, achieving a system output of 480 t/h, with a unit power consumption of only 12.8 kWh/t, and the product fineness and moisture content fully met the requirements for rotary kiln calcination. This highly automated production line, from source crushing to qualified raw material preparation, maximized efficiency.

Related Equipment Recommendations

Mobile Jaw Crusher: As the ideal choice for primary crushing of raw materials, it provides a stable primary crushed product for subsequent processes, acting as a reliable "gatekeeper" for the vertical mill production line.

Mobile Cone Crusher/Mobile Impact Crusher: Used for secondary crushing, it can precisely crush limestone and other raw materials to the optimal feed size for the vertical mill (usually <50mm), optimizing the grinding efficiency of the vertical mill.

Plate Feeders and Heavy-Duty Belt Conveyors: Responsible for the stable transportation of bulk materials from the mobile crushing plant to the pre-homogenization yard or vertical mill raw material silo, they are the "arteries" of the entire raw material preparation system.

Mobile Jaw Crusher

Mobile Cone Crusher

Mobile Impact Crusher

FAQ Frequently Asked Questions

Q1: What is the difference between a cement raw material vertical mill and a cement clinker vertical mill?

A1: Both have the same working principle, but differ in design parameters and wear-resistant materials. Raw material vertical mills mainly process mixed raw materials (limestone, clay, etc.) and focus more on powerful drying capabilities. Cement vertical mills (or cement finish grinding vertical mills) mainly grind clinker with higher hardness, and also incorporate gypsum, slag, etc. The core challenge lies in wear resistance design and coping with the high abrasiveness of clinker. Therefore, higher requirements are placed on the materials of the roller sleeves and grinding disc liners.

Q2: Why is the selection of front-end crushing equipment so important for vertical mills?

A2: The stable and efficient operation of vertical mills heavily relies on a uniform and continuous "material bed". If the material provided by the front-end mobile crushing equipment has excessively large particles, too much fine powder, or a highly uneven particle size distribution, it will lead to increased vibration, reduced output, and increased energy consumption of the vertical mill. A high-quality mobile crushing plant can ensure that the vertical mill receives qualified and reasonably graded "feedstock," which is a prerequisite for maximizing the potential of the vertical mill.

Q3: Is the technology of vertical roller mills manufactured in China reliable? Can they be used in large-scale production lines?

A3: Absolutely reliable and has become a mainstream choice globally. Leading Chinese grinding equipment manufacturers have achieved complete maturity in their vertical mill technology through long-term technological research and development. Currently, domestically produced vertical mills are widely used in extra-large cement production lines with a daily output of 10,000 tons or even 12,000 tons, both domestically and internationally. They operate stably, and their technical indicators (such as power consumption, output, and reliability) have reached world-class levels. They are renowned in the international market for their high cost-effectiveness and timely service.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!