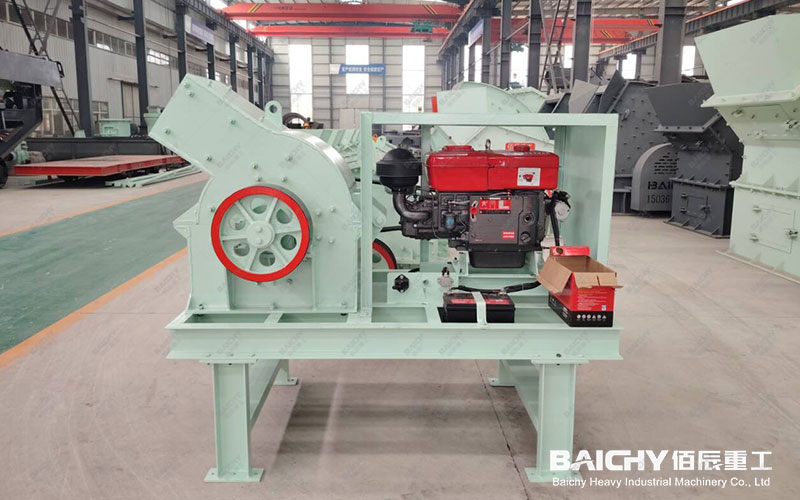

Mobile Diesel Hammer Crusher 400 * 300 Price | Shipping to South Africa

Recently, we've noticed numerous inquiries from international clients, particularly those from mining-active regions like South Africa. The core question focuses on What is the price of a mobile diesel hammer crusher - 400*300? Do you ship to South Africa?

Understanding Core Client Needs: Flexibility and Independence

The client's question directly addresses two core requirements: equipment specifications and logistical feasibility. The 400*300 hammer crusher is a medium-sized crushing unit suitable for small to medium-sized stone quarries, construction waste processing, and primary crushing in mines. The combination of mobile and diesel-powered means the equipment has zero dependence on fixed power sources, offering extremely high site adaptability and relocation flexibility. This makes it ideal for areas with incomplete power grid coverage or frequent changes in operating locations, such as many mines and remote construction sites in South Africa.

Mobile Diesel Hammer Crusher 400 * 300

Core Equipment Analysis of the 400*300 Mobile Diesel Hammer Crusher

This equipment essentially integrates a PC400×300 hammer crusher onto a mobile vehicle chassis, equipped with an independent diesel engine as the power source for the entire system.

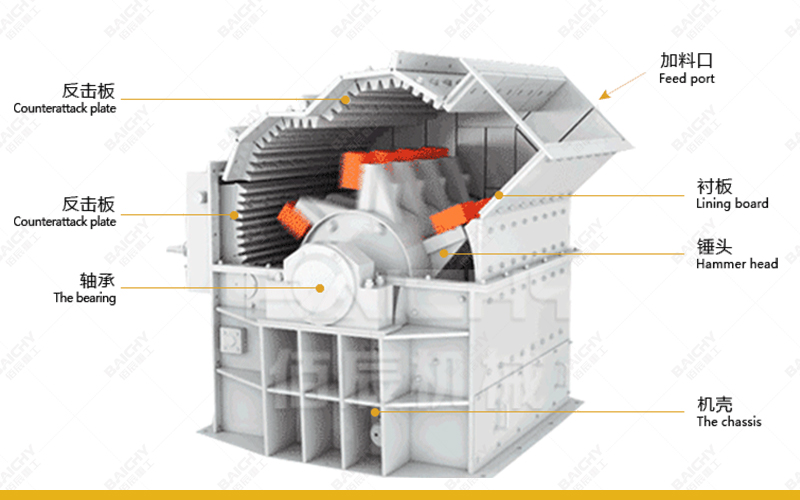

Main Components

1. Crusher Main Unit: PC400×300 hammer crusher, with a feed opening size of 400mm x 300mm, crushing materials through the impact of high-speed rotating hammers.

2. Power System: High-performance diesel engine, providing stable and powerful power, unrestricted by the power grid.

3. Mobile Chassis: Employs heavy-duty tires or crawler tracks for easy road towing or on-site relocation.

4. Auxiliary Systems: Includes a feeder, vibrating screen, and conveyor belt (depending on configuration), forming a flexible mobile crushing production line.

Five Reasons to Choose Our Mobile Diesel Hammer Crusher

Superior Site Adaptability

Diesel power allows for immediate deployment in any remote, off-grid location, making it ideal for developing new mines and undertaking temporary engineering projects.

Integrated Mobility and Flexibility

The compact design and small turning radius allow for flexible movement within the work area, even enabling crushing and moving, significantly reducing material transportation costs.

Powerful and Reliable Crushing Capacity

The hammer crusher main unit, inheriting 20 years of our factory's technology, offers a high crushing ratio and stable output particle size for materials of medium hardness and below (such as limestone, coal gangue, and construction waste bricks).

Rapid Start-up and Low-Cost Operation

Once the equipment arrives on site, almost no complex infrastructure is required; simple commissioning is all that's needed for production. While diesel power requires fuel cost calculations, it saves the substantial expenses and time associated with laying cables.

Robust and Durable Manufacturing Quality

Based on our 20 years of manufacturing experience, key components of the equipment utilize high-quality wear-resistant materials and high-strength steel, ensuring long-term durability under harsh working conditions.

Materials suitable for use with diesel-powered hammer crusher

Global Practice: From China to South Africa

Our equipment of this type has been exported to many countries and regions worldwide. For example, in a small limestone quarry in Zambia, Africa, the customer valued its mobility and diesel power, using it for alternating operations at multiple scattered locations within the mining area. A single unit can process up to 150,000 tons annually, significantly improving mining efficiency. This demonstrates the high applicability of this type of equipment in the African market.

Directly Addressing Your Two Core Questions

What is the Price?

The price of the Mobile Diesel Hammer Crusher (400*300) is not a fixed number, but rather a range depending on the configuration. The price difference between the basic configuration (main unit + chassis + diesel engine only) and the high-end configuration (including feeding and screening system, hydraulic control system, and advanced dust removal device) is significant. Furthermore, fluctuations in raw material prices such as steel and international exchange rates will also affect the final price. We typically offer the most cost-effective customized solutions and transparent quotations based on your specific materials, expected output, and functional requirements. Please provide your detailed needs so we can provide an accurate price.

Do you ship to South Africa?

Yes, we are fully capable of and frequently ship to South Africa. As an experienced international exporter, we provide a full range of export services (including EXW, FOB, CIF, DAP, etc. trade terms) from major Chinese ports (such as Shanghai and Tianjin) to South African ports such as Durban, Cape Town, or Elizabeth. We will handle all export documentation, customs clearance, and ocean freight arrangements to ensure the equipment arrives safely and on time at your designated port.

Expanding Your Options

In addition to the 400*300 model, you may also be interested in the following mobile crushing equipment suitable for the South African market:

• Mobile Jaw Crusher: Suitable for primary crushing, processing larger pieces of raw stone with a wider hardness adaptability.

• Mobile Cone Crusher: Suitable for crushing high-hardness materials, and for secondary crushing where finer particle size and better particle shape are desired.

• Tire-mounted mobile screening station: Can be used in conjunction with existing crushing equipment to achieve fine grading of materials.

Three questions you may have

1: Are diesel engine fuel consumption and operating costs high?

Diesel engine fuel consumption is directly related to equipment load and material hardness. We use high-efficiency, energy-saving engines from well-known brands, resulting in economical fuel consumption under rated operating conditions. Overall, operating costs need to be considered in conjunction with the benefits of eliminating grid construction, electricity costs, and the risk of power outages. In remote areas, it usually offers a greater overall cost advantage.

2: Do you provide installation and technical support after the equipment arrives in South Africa?

We provide detailed installation manuals, drawings, and remote video support. For South African customers, we usually recommend choosing experienced local engineers for installation, or we can send engineers to provide on-site guidance (to be arranged separately) to ensure correct equipment installation. We provide comprehensive after-sales warranty and lifetime technical consultation services, and key spare parts can be shipped to South Africa quickly.

3: Is spare parts supply timely?What is the lifespan of wearing parts?

We equip all exported equipment with a set of commonly used spare parts. Core wear parts such as hammers and liners are made of ultra-wear-resistant materials, ensuring a long service life. We have a spare parts service partner in South Africa and can quickly send emergency spare parts via international express (such as DHL), typically arriving in major South African cities within a week.

Choosing a suitable mobile diesel hammer crusher, especially the classic 400*300 model, can bring revolutionary convenience and efficiency improvements to crushing operations in South Africa and other resource-rich regions. With 20 years of professional manufacturing experience and a mature international export system, we are not only an equipment supplier but also a partner for your project success. Please feel free to contact us for customized solutions and quotations.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!