When recommending 300tph crushing equipment, we can consider the following common configurations to meet the needs of large-scale crushing operations. The following are specific recommendations:

1. Jaw crusher + cone crusher combination

Jaw crusher:

Selection recommendation: PE900X1200 jaw crusher or similar models, this type of jaw crusher has a higher crushing ratio and processing capacity, suitable for coarse crushing operations.

Features: simple structure, stable operation, easy maintenance. A wide range of crushing capacity, which can be adjusted according to material characteristics and production needs.

Output: Can meet the production needs of 300tph.

Cone crusher:

Selection recommendation: HPC220 cone crusher or similar models, this type of cone crusher has the characteristics of high efficiency and wear resistance, suitable for medium and fine crushing operations.

Features: Using advanced crushing technology and structural design, high crushing efficiency, uniform product particle size. Easy to adjust and maintain, reducing operating costs.

Output: In conjunction with the jaw crusher, it can meet the production needs of 300tph.

2. Jaw crusher + impact crusher combination

Impact crusher:

Recommended model: PF1315 impact crusher or similar models. This model of impact crusher is characterized by high efficiency and energy saving and is suitable for crushing materials of medium hardness.

Features: Reasonable crushing chamber design, high crushing efficiency, and good product particle size and shape. Compact structure, small footprint, easy installation, and transportation.

Output: In conjunction with the jaw crusher, it can meet the production needs of 300tph.

3. Supporting equipment

Vibrating feeder: used to feed materials into the crusher evenly and continuously. Recommended model GZD1300X4900 or similar models, the processing capacity can meet the production needs of 300tph.

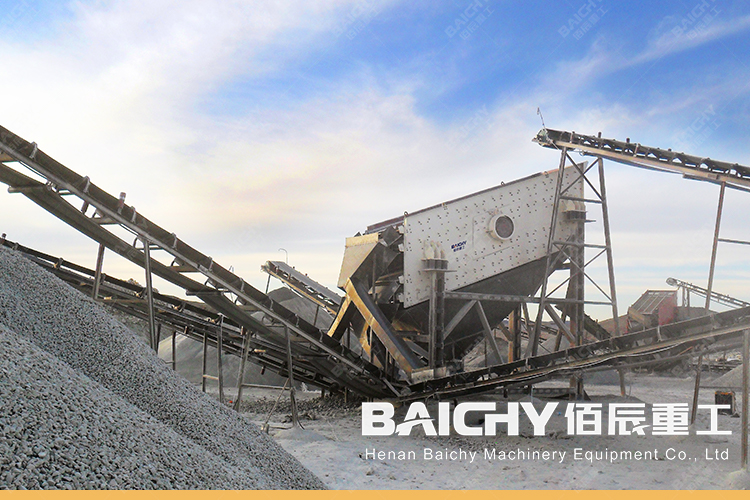

Vibrating screen: used to screen the crushed materials. Recommended model 3YK1860 vibrating screen or similar models, can screen out products of different particle sizes as needed.

Belt conveyor: used to connect various levels of crushing equipment to transport materials to the designated location. The appropriate model and configuration can be selected according to the site layout and output requirements.

4. Precautions

When selecting crushing equipment, the hardness, particle size, humidity, and other characteristics of the material, as well as the production site, power supply, environmental protection requirements, and other conditions should be fully considered.

The equipment configuration should be reasonable, and the processing capacity between crushing equipment at all levels should match each other to avoid bottlenecks or waste.

The installation, commissioning, and maintenance of the equipment should be carried out strictly in accordance with the operating procedures to ensure the safe, stable, and efficient operation of the equipment.

In short, the above-recommended 300tph crushing equipment configuration scheme has a high cost-effectiveness and practicality and can meet the needs of most large-scale crushing operations. The specific configuration scheme to be selected still needs to be evaluated and decided according to the actual situation.