Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The PF1315 impact crusher is a highly efficient secondary crushing machine widely used in the mining, building materials, road, and railway industries. It is suitable for crushing medium-hard materials such as granite, limestone, and basalt. Its high output, low energy consumption, and easy maintenance make it a core piece of equipment in stone production lines.

• High throughput: 130-220 tons/hour, meeting the needs of medium- to large-scale production lines

• High crushing ratio: Excellent particle shape and low flake content

• High wear resistance: High-chromium blow bars provide a longer service life

• Energy-saving and environmentally friendly: Optimized rotor design reduces energy consumption and dust production

• PF1214: 100-180 tons/hour throughput, suitable for small and medium-sized production lines

• PF1315: 130-220 tons/hour throughput, suitable for medium and large-scale production lines

| Model | PFW-1315 |

|---|---|

| Feeder Opening Size(mm) | 860X1520 |

| Max. Feeding Size(mm) | 500 |

| Rotor sizeD*L(mm) | Φ1320X1500 |

| Motor Power(kw) | 160-220 |

| Capacity(t/h) | 130-220 |

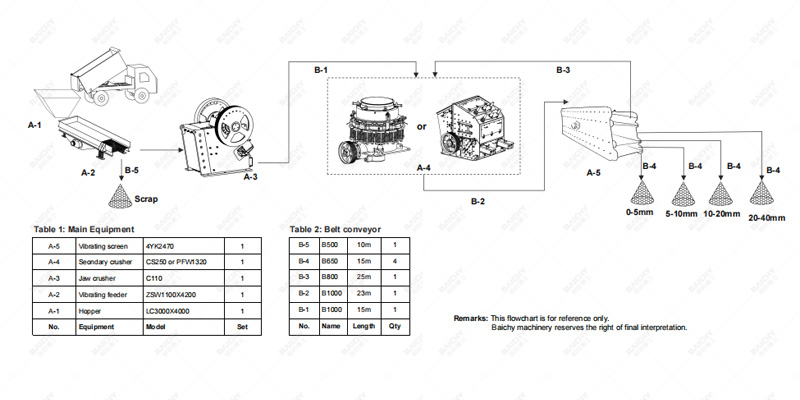

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | LC3000x4000 | 1 |

| 2 | Vibrating feeder | ZSW1100x4200 | 1 |

| 3 | Jaw Crusher | C100 | 1 |

| 4 | Impact Crusher | PFW1315 | 1 |

| 5 | Vibrating Screen | 4YK2470 | 1 |

| 6 | Belt conveyor | B1000 | 2 |

| 7 | Belt conveyor | B650 | 6 |

Granite, a hard rock, faces challenges such as high wear and energy consumption during crushing. The PF1315 impact crusher, with its large capacity, high crushing efficiency, and wear-resistant design, is an ideal choice for 200-300 t/h granite crushing lines.

• Its Mohs hardness is 6-7, which causes severe wear on the equipment.

• Crushing easily produces needle-like particles.

• Traditional equipment suffers from high energy consumption and unstable output.

• Heavy-duty rotor structure: Ø1320 x 1500 mm large rotor for greater impact force.

• High-chromium alloy blow bars: HRC58-62 hardness, extending service life by 30%.

• Hydraulic cover opening: Quickly replace wear parts and reduce downtime.

• Multi-chamber design: Adjustable gap between impact plates to control discharge particle size (adjustable from 0-50 mm).

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!