Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In industries such as mining, sand and gravel aggregates, and construction waste treatment, the 900x1200 jaw crusher (jaw crusher) as a large-scale primary crushing equipment has become the preferred equipment for coarse crushing operations due to its advantages such as high crushing ratio, stable operation, and strong adaptability.

✔ High-strength crushing: suitable for high-hardness materials such as granite, basalt, and iron ore.

✔ Stable and durable: heavy-duty frame + high-manganese steel jaw plate, strong impact resistance, and longer life.

✔ Energy-saving and efficient: optimized cavity design, large crushing ratio, and low energy consumption.

✔ Convenient maintenance: hydraulic adjustment of the discharge port to reduce downtime.

• 900x1200 jaw crusher is suitable for large-scale mines and sand and gravel production lines, with stronger processing capacity and suitable for high-production needs.

• 750x1060 and below models are more suitable for medium-sized crushing stations or mobile crushing equipment.

Raw materials → 900x1200 jaw crusher (coarse crushing) → cone crusher/impact crusher (medium and fine crushing) → vibrating screen → finished aggregate

Large granite crushing production line

• Configuration: 900x1200 jaw crusher + single-cylinder cone crusher+ three-layer vibrating screen

• Output: 280 t/h

• Operation effect: stable equipment, high crushing efficiency, and excellent finished product particle shape.

| Model | PE900x1200 |

|---|---|

| Feeder Opening Size(mm) | 900x1200 |

| Max. Feeding Size(mm) | 750 |

| Outlet adjusting Size(mm) | 95-165 |

| Motor Power(kw) | 132 |

| Capacity(t/h) | 220-450 |

| Overall Dimension(mm) | 3720x2850x3250 |

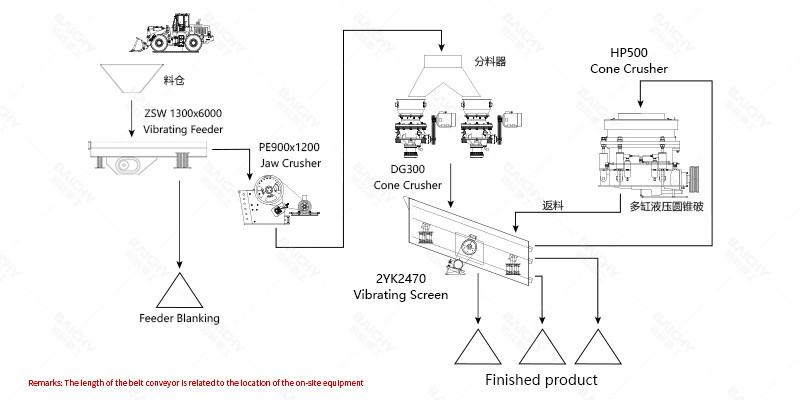

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW1300x6000 | 1 |

| 3 | Jaw Crusher | PE900x1200 | 1 |

| 4 | Cone Crusher | DG300 | 2 |

| 5 | Cone Crusher | HP500 | 1 |

| 6 | Vibrating Screen | 2YK2470 | 1 |

| 7 | Belt conveyor | B1200 | 8 |

Production line overview: efficient crushing of high-hardness granite

For the crushing needs of high-hardness materials (such as granite), we recommend an optimized configuration solution with an output of 300 t/h, using a PE900x1200 jaw crusher + cone crusher combination to ensure high output, low energy consumption, and excellent finished product particle shape, meeting the high standard requirements of sand and gravel aggregates, commercial mixing stations, etc.

• Raw material characteristics: high-hardness granite (compressive strength ≥150MPa)

• Feed particle size: ≤600mm

• Finished product specifications: 0-5mm, 5-10mm, 10-20mm, 20-30mm, 20-40mm (adjustable)

• Core advantages: fast return on investment, energy saving and environmental protection, high degree of automation

1. Jaw crusher + cone crusher golden combination: PE900x1200 jaw crusher for strong coarse crushing, cone crusher for medium and fine crushing to reduce the content of needle flakes.

2. Dual screening system: 2 vibrating screens in parallel to improve screening efficiency and ensure the cleanliness of finished products.

3. Energy-saving design: full-process frequency conversion control, energy consumption is reduced by 15%-20% compared with traditional production lines.

• The PE900x1200 jaw crusher adopts a high-strength manganese steel jaw plate with strong impact resistance, and the life of crushing granite is 8-12 months.

• Cone crusher laminated crushing (HP500) reduces wear and is more suitable for hard rock than impact crusher.

• Multi-stage screening: 5 finished product specifications (0-5mm to 20-40mm) to meet the different needs of commercial mixing, asphalt mixing plants, etc.

• Particle shape optimization: The needle-like content of aggregate crushed by the cone crusher is less than 10%, which is better than the industry standard.

• Return on investment: Calculated at the market price of granite aggregate of 60 yuan/ton, the daily output value is ≈144,000 yuan (20 hours).

• Operating cost: Power consumption ≤1.8 kWh/ton, long replacement cycle for wearing parts, and low overall cost.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!