Spiral Conveyors and Chutes

In the complex process of mineral processing, the transfer of materials from one piece of equipment to the next is a crucial link. It directly affects production efficiency, energy consumption, equipment wear, and ultimately, production costs. Screw conveyors and chutes, as two of the most common and classic continuous conveying devices, each have their irreplaceable advantages and application scenarios. As a mineral processing equipment manufacturer with 20 years of experience, we understand that correctly selecting or combining these two types of equipment, based on material characteristics, process layout, and investment budget, is the cornerstone of building an efficient and stable mineral processing production line.

| Key Words | Spiral Conveyors and Chutes |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

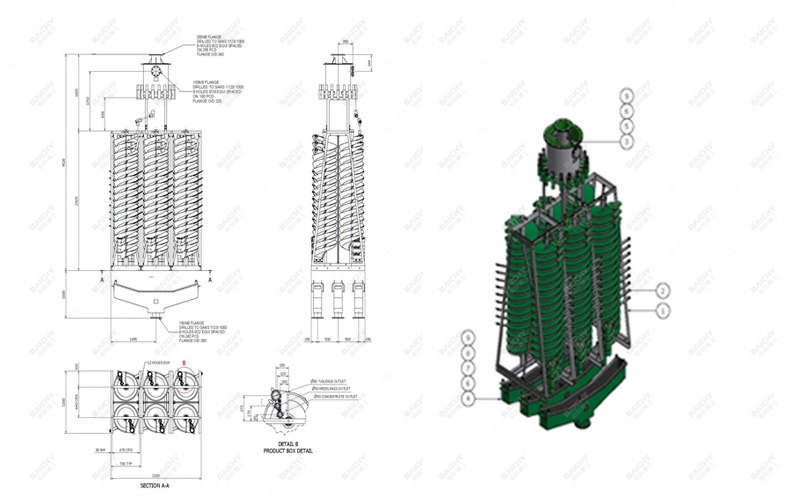

Spiral chute structure diagram

Overview: Basic Principles of the Two Conveying Methods

• Screw Conveyor

A screw conveyor is a mechanical conveying device that moves materials forward in a closed trough using rotating helical blades. It mainly consists of a drive device, a screw shaft, a U-shaped trough, an inlet, and an outlet. Its core function is to utilize the axial thrust generated by the rotation of the helical blades to achieve horizontal, inclined, or even vertical conveying of materials.

• Chute

A chute is a simple device that relies on gravity for self-flowing material transport. It usually consists of a channel made of steel plates, plastic, or lined with wear-resistant materials (such as ceramics, high-molecular-weight polyethylene), installed at a certain inclination angle. Materials slide down the trough under the action of gravity. Its core principle is to utilize gravitational potential energy, requiring no external power.

Advantages Comparison: Tailored Solutions, Each with its Own Strengths

| Feature | Screw Conveyor | Chute |

| Power Source | Electrically driven, consumes energy | Relies entirely on gravity, zero energy consumption |

| Conveying Direction | Flexible, can convey horizontally, inclined, or vertically | Can only convey from a higher to a lower point, direction is limited by layout |

| Sealing | Fully enclosed structure, effectively prevents dust leakage and material contamination, good environmental performance | Generally open or semi-enclosed, prone to dust generation |

| Process Control | Conveying speed and feed rate can be precisely controlled through variable speed motors | Conveying speed is mainly determined by the inclination angle and material characteristics, poor controllability |

| Space and Layout | More adaptable to site layout, can bypass obstacles | Requires continuous, smooth elevation difference space, low layout flexibility |

| Investment and Maintenance | Higher initial equipment investment, requires regular maintenance of moving parts | Simple structure, extremely low investment cost, almost maintenance-free |

| Applicable Materials | Wide range, especially suitable for powdery, granular, and small lump materials, can convey materials with certain viscosity or hot materials (requires special design) | Suitable for blocky, granular dry materials or slurries that are not easily crushed, prone to clogging with viscous materials |

Application Cases: Our Solutions

In an iron ore beneficiation plant project, the client needed to transport fine-grained ore slurry (with a water content of approximately 30%) to a thickener 20 meters away after grinding. Initially, a chute was designed, but the insufficient elevation difference at the site resulted in slow flow and easy sedimentation and clogging of the ore sand. We recommended using a sealed screw conveyor. This equipment not only achieved horizontal conveying, but its enclosed structure prevented slurry splashing and water evaporation, maintaining stable slurry concentration, and was easy to install. Although it increased power consumption, it completely solved the clogging problem, ensuring the continuous and stable operation of the process, and significantly improved overall efficiency.

In another crushing workshop's discharge section, large pieces of crushed raw ore (200-500mm) needed to be transferred from a jaw crusher to a vibrating screen. Due to sufficient elevation difference and the material's resistance to impact, we designed and manufactured a heavy-duty wear-resistant chute lined with ultra-high manganese steel. Its zero energy consumption, high throughput, and impact resistance perfectly match the demanding working conditions of this process stage, saving customers significant equipment investment and operating costs.

Related Equipment Recommendations

In addition to choosing the right conveying equipment, optimizing the entire production line is equally important. We recommend that you consider the following core mineral processing equipment that works in conjunction with our screw conveyors and chutes:

1. Jaw Crusher: As the primary crusher, it produces blocky materials suitable for chute conveying.

2. Ball Mill: After grinding the ore, it often needs to be transported to the next process using a screw conveyor or slurry pump.

3. Hydrocyclone Group: The underflow or overflow after classification is often fed into different processes through distribution chutes or screw conveyors.

Frequently Asked Questions (FAQ)

• FAQ 1: What should I choose when space is limited but I need to change the material conveying direction?

When you need to change the material conveying direction horizontally or at a small angle of elevation, a screw conveyor is a better choice. It can be flexibly arranged, while a chute requires a continuous natural slope, and usually requires multiple turning points when changing horizontal direction, making the design more complex and prone to blockages.

• FAQ 2: How to balance environmental protection and cost when conveying fine-grained materials that easily generate dust?

If the process layout allows for sufficient natural drop, enclosed wear-resistant chutes with dust collection ports at key points should be considered first. If the drop is insufficient or precise feeding is required, a fully enclosed screw conveyor should be chosen. It completely prevents dust leakage and is a more environmentally friendly and reliable solution.

• FAQ 3: What to do if the screw conveyor wears out quickly?

The wear of screw conveyors mainly occurs on the blades and the bottom of the trough. As a professional manufacturer, we offer a variety of solutions: for highly abrasive materials (such as mineral sand), we use tungsten carbide wear-resistant layers welded to the blade edges, use replaceable wear-resistant alloy blades, or recommend troughs lined with ceramic or wear-resistant rubber, significantly extending the equipment's service life and reducing overall maintenance costs.