How To Choose A Suitable Spiral Chute - Mining & Construction

In the mineral processing processes of the mining and construction industries, spiral chutes play a crucial role as efficient and energy-saving gravity separation equipment. However, with the wide variety of products on the market, choosing the most suitable spiral chute for your ore characteristics and production capacity is a challenge for many professionals. As a professional mineral processing equipment manufacturer with 20 years of experience, we will provide you with a comprehensive selection guide.

| Key Words | How To Choose A Suitable Spiral Chute - Mining & Construction |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

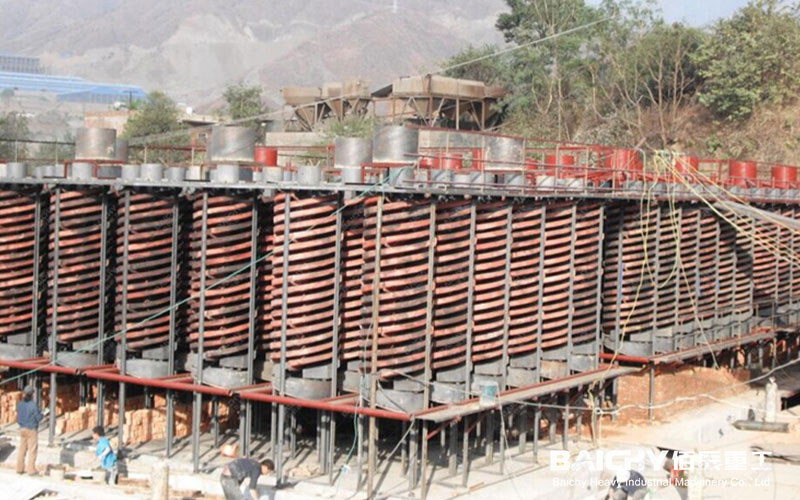

Spiral Chutes: Working Principle and Application Overview

Spiral chutes utilize the differences in density, particle size, and shape between mineral particles. Under the combined action of gravity, centrifugal force, friction, and water flow pressure in the spiral inclined plane, the particles stratify and separate into different layers, thus achieving effective mineral separation. They are mainly suitable for fine-grained (-2mm) iron ore, tungsten ore, tin ore, tantalum-niobium ore, beach sand, gold ore, etc., in the mining industry, as well as for the recovery and de-sludging of fine sand in sand and gravel aggregates in the construction industry.

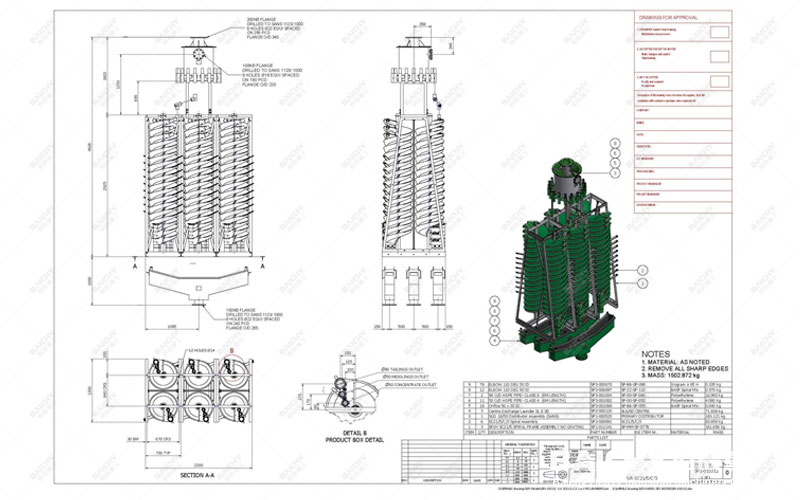

Spiral chute structure diagram

Five Key Considerations for Choosing the Right Spiral Chute

Choosing the right spiral chute is not simply about looking at specifications, but a systematic process. Here are five aspects you need to evaluate carefully.

1. Ore Property Analysis and Feeding Conditions

This is the foundation of the selection process. You must clearly define your material characteristics:

• Mineral composition and density difference: The density difference between the target mineral and gangue mineral is a prerequisite for gravity separation; the greater the difference, the higher the separation efficiency.

• Feeding particle size range: The optimal separation particle size for spiral chutes is usually between 0.03-2mm. Too coarse or too fine particles will seriously affect the separation effect.

• Feeding concentration: Generally, the feeding concentration should be stable between 25%-45%. Too high or too low a concentration will interfere with the normal stratification of particles.

2. Equipment Structure and Material Selection

The quality of the equipment itself directly determines its lifespan and stability.

• Spiral trough design: Including the number of spirals (e.g., 3, 5, 6 spirals), pitch, spiral diameter (e.g., φ600, φ900, φ1200, etc.), and cross-sectional shape. Larger diameters are suitable for coarse, heavy materials, while smaller diameters are suitable for fine, light materials.

• Material and Wear Resistance: The trough is typically made of fiberglass lined with a wear-resistant layer (such as polyurethane or alumina ceramic). Its wear resistance directly affects the maintenance costs and downtime of the mineral processing equipment. We use high-strength fiberglass and imported polyurethane composite materials to ensure long-lasting durability under harsh working conditions.

3. Process Flow and Processing Capacity Matching

• Processing Capacity (tons/hour): Based on your plant size and processing volume, select the appropriate spiral chute model and number of units to avoid over- or under-capacity.

• Classification and Sorting Principles: It usually needs to be combined with vibrating screens, cyclones, etc., to achieve "narrow-grade" separation, which is key to improving the separation efficiency of the spiral chute.

4. Operation, Maintenance, and Cost-Effectiveness

• Ease of Operation: An excellent spiral chute should be flexible in adjustment (such as cutter height and angle), operate smoothly, and require no complex power.

• Maintenance Costs: Choosing equipment with good wear resistance can significantly reduce the frequency of spare parts replacement and labor costs, thus improving the return on investment in the long run.

5. Manufacturer's Experience and Technical Support

An experienced manufacturer can provide comprehensive support from mineral processing tests, process configuration, installation guidance to operation training. With 20 years of industry experience, we can provide small-scale laboratory tests based on your ore samples and recommend the optimal spiral chute configuration plan based on the test data, which is the "invisible value" in the selection process.

Case Study: Efficiency Improvement Solution for a Certain Iron Ore Processing Plant

Background: A medium-sized iron ore plant in China had poor recovery of fine-grained iron ore in its original process, resulting in high tailings grade.

Our Solution: We first conducted detailed ore amenability tests to determine the optimal separation particle size and parameters. Then, we configured 6 sets of GL-1200 type 5-head spiral chutes for fine separation of the classified -0.1mm material.

Results: After project implementation, the iron concentrate recovery rate increased by approximately 8%, and the tailings grade was effectively reduced, generating considerable economic benefits for the owner every year. After two years of operation, the wear-resistant lining showed minimal wear, and the operating costs were very low. H2: Recommended Related Equipment

Spiral chutes usually do not operate in isolation. An efficient mineral processing system includes:

• Feeding equipment: such as vibrating feeders, to ensure uniform and stable feeding.

• Classification equipment: such as high-frequency vibrating screens and hydrocyclones, for pre-classification of materials.

• Dewatering equipment: such as dewatering screens and thickeners, used for dewatering the concentrate and tailings from the spiral chute.

Frequently Asked Questions (FAQ)

1. What are the advantages of spiral chutes compared to shaking tables?

Spiral chutes have a large processing capacity, small footprint, no moving parts, simple maintenance, and extremely low energy consumption. They are suitable for rough and fine separation of materials with large processing volumes and low grades. Shaking tables have higher separation accuracy and a larger enrichment ratio, but a smaller processing capacity. They are usually used for fine separation after the spiral chute, and the two are often used in combination.

2. What should be paid attention to when installing a spiral chute?

The core is "horizontal" and "vertical". A spirit level must be used to ensure that the entire equipment is installed horizontally, and the centerlines of each spiral head must be vertically aligned. The feed needs to be evenly distributed to each spiral groove, and the feed pressure and concentration should be stable at the set values.

3. How to determine if the separation effect of the spiral chute is normal?

This can be determined by observation and sampling analysis. Under normal circumstances, the mineral banding on the spiral groove surface should be clear and distinct (usually the inner circle is the concentrate, the outer circle is the tailings, and the middle is the middlings). If the banding is disordered, check whether the feed particle size, concentration, and the position of the splitter are accurate, and make corresponding adjustments.