Spiral Chute | Efficient & Low-Cost Gravity Separator

In the field of mineral processing, efficiency and cost are always the core considerations in equipment selection. How can you maximize recovery rates while minimizing operating energy consumption and maintenance costs? The spiral chute, with its unique design and separation principle, provides the perfect answer. As a mineral processing equipment manufacturer with 20 years of experience, we will delve into this classic equipment, known as an efficient and low-cost gravity separator and share our professional insights and practical experience.

| Key Words | Spiral Chute | Efficient & Low-Cost Gravity Separator |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is a Spiral Chute? Overview of Working Principles

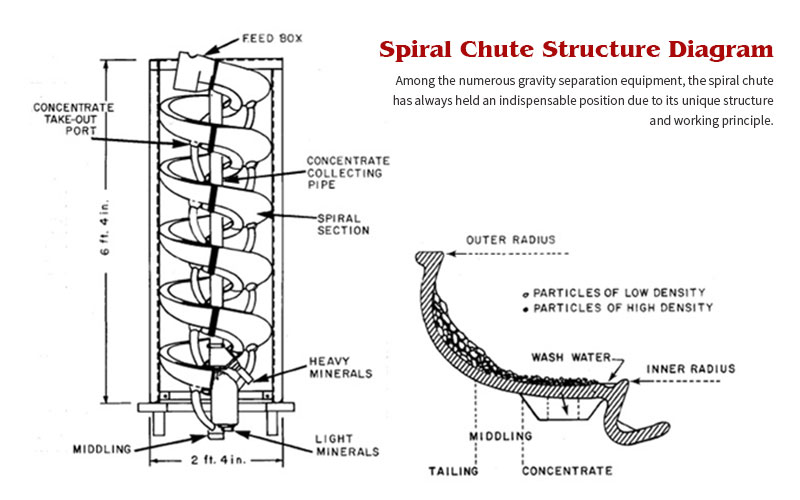

A spiral chute is a gravity separation device that utilizes the combined action of multiple force fields, including gravity, centrifugal force, hydrodynamic force, and friction. It requires no external power source, relying solely on the gravity of the mineral slurry flowing down the spiral channel to achieve mineral separation.

Spiral chute structure diagram

Step-by-Step Analysis of the Core Working Principle

1. Feeding: The mineral slurry is fed uniformly from the top of the spiral chute.

2. Flow and Stratification: As the mineral slurry flows and rotates downwards along the spiral channel, the mineral particles stratify under the combined action of gravity, centrifugal force, and other forces: heavier mineral particles with higher specific gravity settle to the inner edge, while lighter mineral particles with lower specific gravity are distributed on the outer edge.

3. Separation and Collection: At the end of the spiral chute, a splitter separates the stratified mineral flow into concentrate, middlings, and tailings according to their specific gravity, thus completing the separation process.

Outstanding Advantages of the Spiral Chute: Why is it a Cost-Effective Choice?

Compared with other mineral processing equipment, the advantages of the spiral chute are obvious, which is the secret to its enduring success.

1. Extremely High Energy Efficiency and Low Operating Costs

• Zero power consumption: The entire separation process relies entirely on gravity flow, consuming no electricity, significantly reducing the power costs of the mineral processing plant.

• Simple structure, low investment: The equipment has no moving parts and a robust structure, resulting in significantly lower initial investment costs compared to complex equipment such as flotation machines and shaking tables.

• Extremely low maintenance costs: Due to the absence of easily worn moving parts, daily maintenance is minimal, requiring only periodic checks of the chute body for wear, saving a significant amount of labor and spare parts costs. 2. High Processing Capacity and Easy Operation

• The equipment has a large processing capacity, especially suitable for processing medium and fine-grained (-2mm) minerals, resulting in high processing efficiency per unit area.

• Operating parameters (feed concentration, feed rate) are easy to adjust. Once adjusted, the operation is very stable, requiring low technical skills from operators.

3. Environmentally Friendly and Highly Adaptable

• The separation process usually only requires the addition of water, requiring little or no chemical reagents, making it environmentally friendly and the wastewater easy to treat.

• Applicable to a variety of minerals, such as iron ore, ilmenite, chromite, cassiterite, tungsten ore, beach sand deposits, and the recovery of useful components from tailings.

Case Study Sharing: Our Solution

In our 20 years of service, spiral chutes have been successfully applied in numerous projects worldwide. For example, in a large beach sand ilmenite processing plant in Southeast Asia, we designed and configured a double-layer spiral chute unit for roughing and tailings removal. Ultimately, with an initial ore grade of only 4.5% TiO₂, a rough concentrate with a grade of over 32% was obtained through a single stage of roughing, reducing the tailings grade to below 1%, and achieving a recovery rate exceeding 85%. This solution saved the client over 60% in initial equipment investment, and saved hundreds of thousands of yuan in electricity costs annually. The client highly praised the efficient and low-cost results.

Equipment Recommendation and Configuration Suggestions

Based on mineral properties and plant scale, we offer perse configurations:

• Fiberglass spiral chute: The chute surface is wear-resistant and corrosion-resistant, with a long service life, making it our main recommended model.

• Cast iron base or steel frame structure: Ensures the stability of the equipment during long-term operation.

• Customized service: We can provide non-standard designs with different spiral diameters, pitches, and number of turns based on the user's ore characteristics, and conduct process simulations to optimize the overall recovery plan.

Frequently Asked Questions (FAQ)

Q1: What are the requirements for the particle size range of the ore for the spiral chute?

A1: The optimal particle size range for spiral concentrators is 0.1-2 mm. For fine particles smaller than 0.1 mm, the separation efficiency decreases, and it usually needs to be used in conjunction with other fine particle processing equipment (such as centrifuges).

Q2: How to control the separation effect of the spiral concentrator?

A2: The main control points are the feed concentration and feed rate. Generally, the best results are achieved when the feed concentration is controlled between 20% and 40% (by weight). Stable feeding is a prerequisite for ensuring separation performance. By adjusting the position of the splitter, the yield and grade of the concentrate and tailings can be changed.

Q3: What are the special features of your spiral concentrators in terms of durability?

A3: With 20 years of manufacturing experience, we use high-strength, anti-aging fiberglass integrated molding technology to manufacture the trough body. The inner lining uses wear-resistant elastic materials or ceramic tiles, and key parts are reinforced. Our products have an average trouble-free operating time that is more than 30% higher than the industry standard in harsh mining environments.

In the increasingly competitive mining market, choosing an efficient, reliable, and low-cost mineral processing equipment is key to improving project profitability. Spiral concentrators, having stood the test of time, remain the preferred solution for roughing, scavenging, and pre-concentration of heavy minerals due to their excellent cost-effectiveness. With 20 years of professional experience, we are committed to providing you with the most suitable gravity separation solutions to help you reduce costs, increase efficiency, and create greater value.