Sand Washing Recycling and Dewatering Machine

As a manufacturer of mining crushing and grinding equipment with 20 years of extensive experience, we understand that in sand and aggregate production lines, the sand washing process is not only crucial for ensuring the quality of the finished sand but also a major source of water consumption and fine sand loss. Traditional sand washing equipment often faces challenges such as high fine sand loss rates, difficulty in treating muddy water, and unstable moisture content in the finished sand. Today, we will delve into an efficient and environmentally friendly solution: the integrated sand washing, recovery, and dewatering machine.

| Key Words | Sand Washing Recycling and Dewatering Machine |

|---|---|

| Product Model | Sand Washing And Dewatering Integrated Equipment |

| Feed Size | ≤10mm |

| Motor Power | 1.6-15KW |

| Capacity | 30-250t/h |

| Core Functions | It features integrated functions for cleaning, grading, dewatering, and fine sand recovery. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

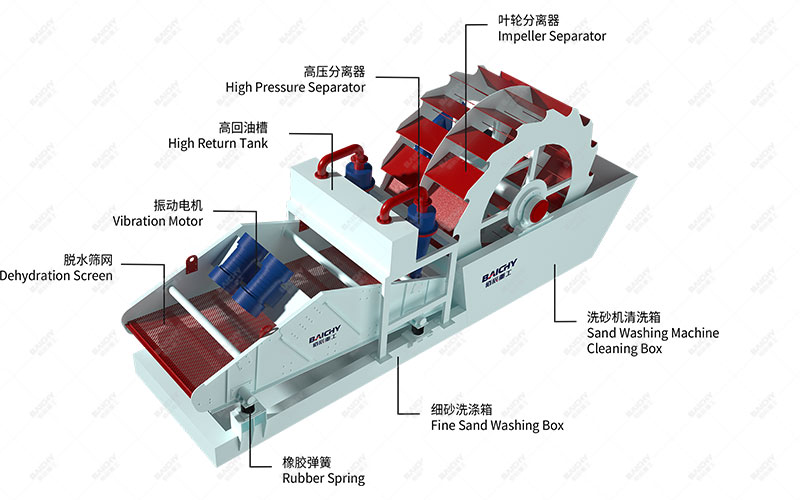

Integrated Sand Washing, Recovery, and Dewatering Machine: Core Overview

The integrated sand washing, recovery, and dewatering machine, as the name suggests, is an innovative device that integrates multiple functional modules, including fine sand recovery, mud dewatering, and finished sand dewatering and drying. It is not simply an upgrade of traditional wheel or spiral sand washing machines, but a systematic solution for fine sand recovery and wastewater purification. Its core working principle is: the muddy wastewater discharged from the sand washing machine is introduced into the equipment, and through steps such as centrifugal separation and high-frequency dewatering screening, fine sand particles above 0.16mm are efficiently recovered, while simultaneously achieving mud concentration and clean water recycling, significantly improving economic benefits and resource utilization.

Outstanding Advantages of the Integrated Machine

Compared with traditional sand washing processes, the integrated sand washing, recovery, and dewatering machine demonstrates unparalleled comprehensive advantages.

1. Improved Economic Efficiency, Eliminating Resource Waste

The equipment can effectively recover 5%-20% of the fine sand particles lost in traditional sand washing. Based on a production line with a capacity of 100 tons per hour, tens of tons of finished sand can be recovered daily, directly translating into considerable economic benefits. This is equivalent to extracting real value from "waste."

2. Environmental Compliance, Achieving Green Production

Sand Washing Recycling and Dewatering Machine

The equipment can transform sand washing wastewater into clean water and mud cakes. The clean water can be recycled for sand washing, greatly reducing fresh water consumption and wastewater treatment costs; the resulting mud cakes are easy to transport and handle, ensuring that the entire production line meets increasingly stringent environmental requirements and helps enterprises achieve green and sustainable development.

Optimized Finished Sand Quality, Enhanced Market Competitiveness

The recovered fine sand can effectively supplement the gradation of the finished sand, making its particle size distribution more reasonable and its fineness modulus easier to control. Meanwhile, the finished sand processed by the dewatering screen has a moisture content of approximately 12%-15%, effectively solving problems such as excessive moisture, clumping, and transportation difficulties, thus increasing product added value and market acceptance.

Compact Structure, Reduced Operating Costs

The integrated design occupies a small footprint, reducing civil engineering and piping layout costs. High degree of automation simplifies operation and maintenance, reducing labor costs. The water circulation system reduces external water supply and wastewater treatment costs, resulting in significantly lower overall operating costs.

Successful Application Cases

In a large-scale construction sand and gravel production project in South China, we equipped the customer with an LZ series integrated sand washing, recycling, and dewatering machine. The raw material for this project was granite sand. The original production process suffered from serious fine sand loss, and the finished sand had a high mud content and high moisture content.

• Results after modification:

◦ Fine sand recovery rate reached over 90%, increasing finished sand output by approximately 15%.

◦ The fineness modulus of the finished sand was stable, the mud content met the standards, and the moisture content was reduced to about 13%, making it the designated sand for local commercial concrete plants.

◦ Achieved a water recycling rate of over 95% for sand washing, meeting the environmental standard of "zero" wastewater discharge.

◦ The customer recovered the equipment investment cost within 8 months through the value of the recovered fine sand.

How to Choose the Right Integrated Machine for You?

When choosing an integrated sand washing, recycling, and dewatering machine, the following points should be considered:

1. Processing capacity: Match the model according to your production line's hourly output and wastewater discharge volume.

2. Material characteristics: Consider the hardness, mud content, and initial particle size distribution of the raw materials.

3. Finished product requirements: Specific standards for the fineness, moisture content, and gradation of the finished sand.

4. Site limitations: Assess the compatibility of the equipment size with the existing layout.

5. Manufacturer experience: Prioritize reliable suppliers like our company, which have many years of industry experience and provide comprehensive services from design to installation and commissioning.

Frequently Asked Questions (FAQ)

Q1: What is the difference between an integrated machine and a traditional sand washing machine + fine sand recycling unit?

A1: Traditional configurations consist of two or more independent devices connected in series, resulting in a large footprint, complex connections, and less efficient coordination. The integrated machine features a highly integrated modular design, saving 30%-50% of space, optimizing internal processes, reducing energy consumption, and making installation and maintenance simpler and faster.

Q2: What is the quality of the recovered fine sand? Will it affect the sand gradation?

A2: The recovered fine sand mainly consists of high-quality particles ranging from 0.16mm to 0.6mm, with high cleanliness. Its addition not only increases the total output but also effectively fills in the missing intermediate particle sizes, making the finished sand gradation continuous and reasonable, improving overall quality, and fully meeting construction sand standards.

Q3: Is the equipment's water and power consumption high?

A3: On the contrary. Due to its core advantage of water resource recycling, the overall water consumption is reduced by more than 80% compared to traditional direct-discharge sand washing. In terms of power consumption, although the recycling function is added, due to optimized design and reduced energy consumption for subsequent wastewater treatment, the comprehensive power consumption per unit of product has not increased significantly, and may even be reduced due to increased output.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!