Sand Washing And Dewatering Machine

In modern mining crushing and manufactured sand production lines, the cleanliness and moisture content of raw materials directly affect the quality and value of the finished aggregate. As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that an efficient production line requires not only powerful crushers and sand making machines, but also sophisticated downstream processing equipment. The sand washing and dewatering machine is the core equipment in this process, determining the quality and commercial competitiveness of the final sand and gravel product.

| Key Words | Sand Washing And Dewatering Machine |

|---|---|

| Product Model | Sand Washing And Dewatering Integrated Equipment |

| Feed Size | ≤10mm |

| Motor Power | 1.6-15KW |

| Capacity | 30-250t/h |

| Core Functions | It features integrated functions for cleaning, grading, dewatering, and fine sand recovery. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is a sand washing and dewatering machine?

A sand washing and dewatering machine, also known as a fine sand recovery and dewatering integrated machine or dewatering screen, is a high-efficiency and environmentally friendly equipment that integrates cleaning, dewatering, and grading functions. It is mainly used to wash away mud, stone powder, and other impurities from manufactured sand or natural sand, and separates sand and water through high-frequency vibration and screens, ultimately producing clean, high-quality finished sand with low moisture content.

Brief Description of Working Principle

This equipment combines the functions of sand washing and dewatering screening. The material first enters the washing tank, where it is ground against each other under the action of the impeller, stripping off surface impurities; then, under the action of a strong water flow, the impurities are carried away, and the clean sand and gravel material is sent to the high-frequency vibrating dewatering screen. Under the action of the vibrating motor, water is quickly discharged through the screen holes, while the dewatered sand is evenly discharged from the end of the screen surface, achieving efficient dewatering.

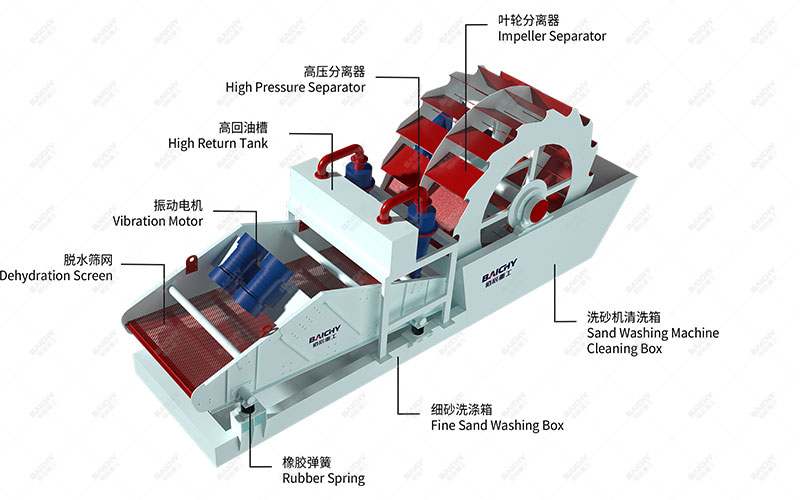

Structural-diagram-of-the-sand-washing-and-dewatering-integrated-equipment

Core Advantages of the Sand Washing and Dewatering Machine

Improved Finished Sand Quality

• High cleanliness: Effectively removes mud and stone powder coating the surface of sand particles, making the sand cleaner and with a more reasonable gradation.

• Low moisture content: Through vibration dewatering, the moisture content of the finished sand can be effectively reduced to about 10-15%, meeting the requirements for high-standard concrete sand and avoiding dripping and caking during transportation.

Enhanced Production Line Efficiency

• Resource recovery: Fine sand (above 0.16mm) lost by traditional sand washing machines can be effectively recovered, reducing resource waste and directly improving economic benefits.

• Environmental protection and energy saving: The use of a circulating water system greatly reduces fresh water consumption and wastewater discharge, meeting the requirements of green mine construction. • Fast Return on Investment: The equipment operates stably and requires simple maintenance. The increased revenue from improved sand quality and recovery rate allows for a quick return on investment.

Sand Washing And Dewatering Machine

Actual Application Case Study

Our client, a large building materials group in East China, introduced our LX series high-efficiency sand washing and dewatering integrated machine into their artificial sand production line with an annual output of 5 million tons.

• Before Application: The finished sand had a high mud content and a moisture content of approximately 20%, resulting in weak market competitiveness and significant loss of fine sand.

• Solution: We installed two LX-3620 sand washing and dewatering machines at the end of their production line.

• Application Results:

◦ The mud content of the finished sand decreased from 3.5% to below 1.0%, meeting the Class I building sand standard.

◦ The moisture content stabilized at around 12%, allowing for direct loading and sale.

◦ The fine sand recovery rate reached over 90%, generating over one million yuan in additional economic benefits annually.

◦ A closed-loop water circulation system was achieved, resulting in zero wastewater discharge.

Equipment Selection and Matching Recommendations

Choosing the right sand washing and dewatering machine requires considering factors such as raw material characteristics, processing capacity, and site conditions. We offer a full range of models with capacities from 50 tons to 500 tons per hour. Generally, we recommend:

1. Matching with a sand making machine: Combining it with our vertical shaft impact crusher (shaping machine) forms a "sand making - sand washing - dewatering" golden combination for producing high-quality fine sand.

2. Combining with a fine sand recovery machine: For materials with extremely high powder content, it is recommended to first concentrate the material using a fine sand recovery machine before deep cleaning and dewatering with the sand washing and dewatering machine for better results.

3. Considering variable frequency control: Our high-end models support variable frequency speed control, allowing for flexible adjustment of vibration frequency and water volume according to material conditions, achieving multi-purpose functionality.

Frequently Asked Questions (FAQ)

1. What materials can the sand washing and dewatering machine process?

In addition to the most commonly used artificial sand and river sand, it is also suitable for cleaning and dewatering various materials such as mine tailings recovery, coal slime dewatering, quartz sand cleaning, and sand and aggregate systems in hydropower stations.

2. What is the minimum moisture content of the sand after dewatering?

Under ideal operating conditions (such as appropriate feed concentration and reasonable screen configuration), our equipment can control the moisture content of the finished sand to between 10-15%. This indicator fully meets the production requirements of commercial concrete plants and most dry-mix mortar manufacturers.

3. Is the equipment difficult to maintain? What should I pay attention to?

Maintenance is very simple, the core is regular inspection:

• Vibration motor: Regularly check the tightness of the bolts and the lubrication of the bearings.

• Screen: Regularly check for wear and tear, and replace it promptly to ensure dewatering efficiency.

• Washing tank: Check the wear of vulnerable parts such as the impeller when the machine is stopped.

Our equipment adopts a modular design, and key components are easy to replace. We will also provide detailed maintenance manuals and operational training.

In today's sand and gravel industry, which is moving towards high-quality and green development, an efficient sand washing and dewatering machine is no longer an "option" for the production line, but a "standard configuration" to enhance product added value and market competitiveness. With 20 years of technological expertise and hundreds of successful cases, we can not only provide you with stable and reliable equipment, but also customize the most economical sand and gravel washing and dewatering solutions for you.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!