Sand Washing & Recycling Machine

In the fields of mining, sand and aggregate production, construction waste recycling, and large-scale engineering construction, sand washing and recycling are crucial. Unwashed sand contains a large amount of mud, stone powder, and other impurities, which seriously affect the quality of the finished product. As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that an efficient and reliable sand washing and recycling machine plays an irreplaceable role in improving the quality of finished sand, saving water resources, and increasing corporate profits. This article will provide a comprehensive introduction to sand washing and recycling machines to help you understand their value in detail.

| Key Words | Sand Washing & Recycling Machine |

|---|---|

| Product Model | Sand Washing And Dewatering Integrated Equipment |

| Feed Size | ≤10mm |

| Motor Power | 1.6-15KW |

| Capacity | 30-250t/h |

| Core Functions | It features integrated functions for cleaning, grading, dewatering, and fine sand recovery. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Why is Sand Washing and Recycling So Important?

The increasing depletion of natural sand resources and stricter environmental policies have made manufactured sand the mainstream in the market. However, during the crushing and sand making process, a large amount of "dirty sand" with attached stone powder and mud is produced. Direct use of this sand can lead to problems such as reduced concrete strength and poor durability. Therefore, a sand washing and recycling machine is not only a cleaning device, but also a "quality gatekeeper" that ensures the final aggregate product meets national standards and increases product added value.

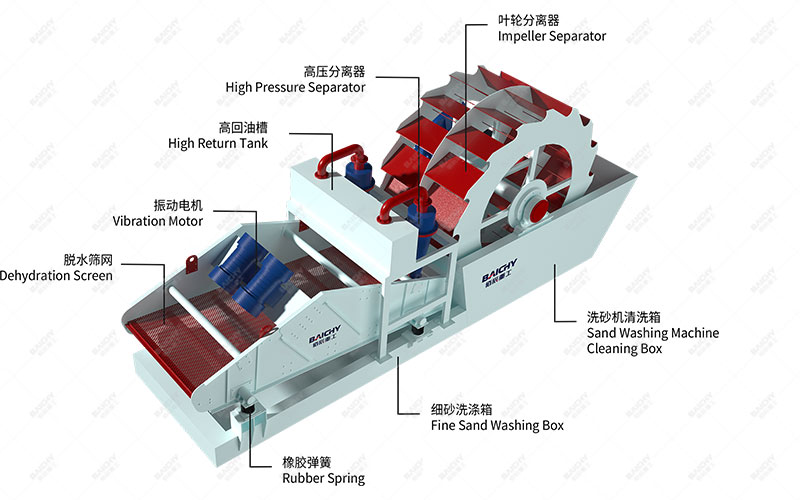

Structural-diagram-of-the-sand-washing-and-dewatering-integrated-equipment

II. How Does a Sand Washing and Recycling Machine Work?

A sand washing and recycling machine is typically an integrated system, with the core objectives of "washing" and "recycling."

Core Components

1. Washing device: The core component, usually using a wheel bucket or spiral structure, uses the rotation of the impeller to agitate the sand, allowing it to fully contact the water flow and remove surface impurities.

2. Dewatering and separation device: The washed sand has a high water content and needs to be dewatered through a high-frequency dewatering screen or a dewatering fine sand recovery machine to produce clean finished sand with a suitable water content (usually controllable at 10%-15%).

3. Fine sand recovery device: This is key to improving economic efficiency. Traditional sand washing loses a large amount of fine sand particles smaller than 0.16mm. The recovery device (such as a hydrocyclone and high-frequency dewatering screen combination) can effectively recover this valuable resource, reducing sand loss to within 5%-10%.

4. Wastewater sedimentation and circulation system: This system processes the mud and water generated during cleaning, enabling the reuse of clean water, significantly saving water resources, and achieving zero environmental discharge.

Workflow Overview

Raw sand containing clay and silt enters the washing chamber → It is tumbled and scrubbed by the impeller → Impurities are discharged through the overflow port → Cleaned sand enters the dewatering screen for dewatering → Slurry enters the fine sand recovery machine to extract fine sand → Clean water is recycled, and mud and sand are settled and filtered.

III. Core Advantages of the Equipment: Reasons to Choose a Professional Manufacturer

Compared with simple washing equipment, a professional sand washing and recycling system offers multiple advantages:

• High cleaning efficiency and superior finished product: Deep cleaning ensures that the clay and silt content of the finished sand fully meets the standards for construction sand, resulting in higher selling prices.

• Fine sand recovery, doubled efficiency: Effectively recovers fine sand lost in traditional processes, increasing the total sand output rate by 8-15%, directly translating into economic benefits.

• Energy-saving and environmentally friendly, circular utilization: Adopting a closed-loop water circulation system, daily water consumption can be reduced by more than 80%, and clean treatment of mud and slurry is achieved, meeting stringent environmental requirements.

• Durable and reliable, easy maintenance: As a manufacturer with 20 years of experience, our equipment uses high-quality components such as wear-resistant steel plates and heavy-duty bearings, with a reasonable structural design, low failure rate, and lower long-term operating costs.

Sand Washing & Recycling Machine

IV. Application Case Sharing

Case Study: A large green building materials production base in Central China

This customer originally used a conventional spiral sand washing machine, resulting in serious fine sand loss, poor finished sand gradation, and significant wastewater discharge pressure. We designed a complete solution for them, including a wheel-type sand washing and recycling machine, a high-frequency dewatering screen, and a fine sand recovery hydrocyclone.

• Results: The clay content of the finished sand decreased from 5% to less than 1%, meeting the Class I sand standard; the fine sand recovery system recovered approximately 80 tons of high-quality fine sand daily; and 100% recycling of sand washing water was achieved. The customer's investment costs were recovered within 8 months through product value-added and recovery benefits.

V. Related Equipment Recommendations

For an efficient sand production line, the sand washing and recycling machine needs to be perfectly matched with the front-end equipment:

1. Jaw crusher: For coarse crushing of raw materials.

2. Cone crusher/Impact crusher: For medium and fine crushing to produce suitable crushed stone. 3. Sand Making Machine (Impact Crusher): This machine crushes crushed stone into manufactured sand, which is a crucial preliminary step before the sand washing and recycling machine.

4. Vibrating Screen: Multi-stage screening separates materials into different sizes.

VI. Frequently Asked Questions (FAQ)

Q1: Can the processed sand meet the standards for construction sand?

A1: Absolutely. The professionally designed sand washing and recycling machine system can precisely control the clay content, stone powder content, and particle size distribution of the finished sand, ensuring it consistently meets the national standard GB/T 14684-2011 "Construction Sand," and can even meet the requirements for high-performance concrete sand.

Q2: Is the equipment's water and power consumption high?

A2: Modern advanced sand washing and recycling machine systems emphasize energy saving and environmental protection. Through fine sand recovery and wastewater circulation and sedimentation systems, the washing water can be recycled, requiring only a small amount of water to compensate for evaporation and water carried away, significantly reducing fresh water consumption. Power consumption is mainly concentrated in the drive motor. The use of high-efficiency motors and reasonable transmission design ensures low energy consumption per ton.

Q3: Does the equipment need to be customized for raw materials with different hardness and clay content?

A3: Yes, the best solution often requires a customized approach. Our engineers will recommend the most suitable washing machine model (wheel-type or spiral-type) and configure the corresponding recovery and dewatering modules based on your raw material characteristics (such as Mohs hardness, initial clay content, and particle composition), expected output, and finished product requirements, to ensure optimal cleaning effect and economic benefits.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!