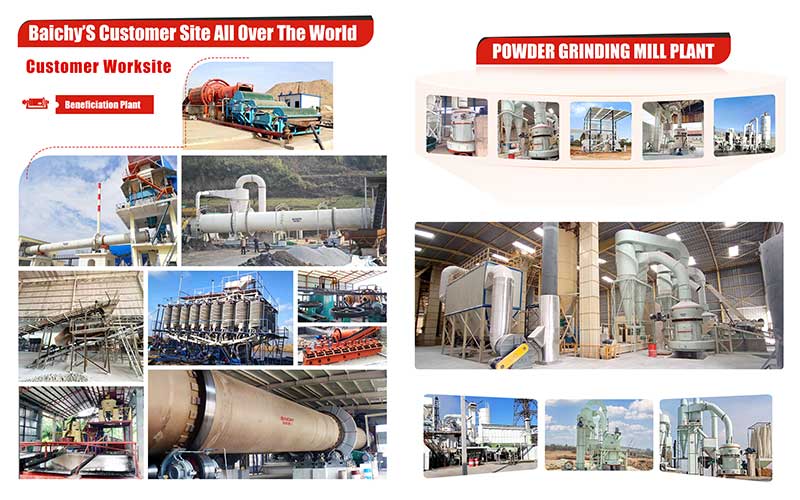

Rotary Dryer Manufacturer in China

Rotary dryers, as key drying equipment in mining, metallurgy, and chemical industries, have seen increasing technological advancements and wider market applications in the context of China's rapid manufacturing development. With the tightening of China's environmental protection policies and the advancement of the intelligent manufacturing strategy, domestically produced rotary dryers have achieved significant breakthroughs in energy efficiency, automation levels, and durability, gradually replacing some imported equipment and becoming the main drying equipment in domestic mining, building materials, and other industries.

| Product Name | rotary dryer china |

| General Use | Mechanical Equipment |

| Brand Name | Baichy |

| OEM/ODM | Support |

| Place of Origin | Zhengzhou,Henan |

| Condition | New |

| Application | Sand making,Chemical...etc |

| Export countries | United Kingdom,Japan,France...etc |

| Export region | Europe,Africa,Middle East... |

| Design Style | Modern |

| Certificate | SGS,ISO:9001... |

| Spare parts supplying | Anytime |

| MOQ | 1 |

| Warranty | 12 months |

| Color | Customized |

| Product features | mobility,security... |

| Packaging Details | Carton |

| After sale service | Online support, Video technical support |

| Lead time (days) | 15-30(To be negotiated) |

What is a rotary dryer?

A rotary dryer is a continuous drying device that uses a rotating drum to allow wet materials to fully contact a hot airflow, thereby evaporating moisture. It mainly consists of a rotating drum, heating device, transmission system, support device, and sealing components, and is suitable for drying various materials such as granular, lump, and powder materials. In the Chinese manufacturing system, this type of equipment has been standardized and serialized, capable of meeting the needs of different production capacities and material characteristics.

Core Advantages of Chinese-Made Rotary Dryers

1. High Energy Efficiency and Energy-Saving Design: Adopting a composite heat exchange structure and waste heat recovery technology to reduce energy consumption, complying with Chinese green manufacturing standards.

2. Strong Adaptability: Customizable design for special materials such as high-humidity and high-viscosity materials, suitable for various mining materials such as iron ore, coal powder, and slag.

3. Intelligent Control: Integrated PLC automatic control system for real-time monitoring and adjustment of temperature, rotation speed, and feed rate, improving drying uniformity.

4. Durability and Low Maintenance: The drum is made of high-temperature and corrosion-resistant steel, and the transmission components are reinforced, suitable for continuous heavy-duty operation, reducing downtime.

1.8x20M Single Cylinder Rotary Dryer Shipped To Kazakhstan

Practical Application Case

A large iron ore company faced problems of low drying efficiency and high energy consumption for iron concentrate powder. Our company customized a rotary dryer with a diameter of 3.2 meters and a length of 20 meters for them, using a segmented indirect heating and cyclone dust removal design. After commissioning, the drying efficiency increased by approximately 35%, fuel costs decreased by 25%, and dust emissions met national environmental protection standards. The equipment has been operating stably for over 5 years. Related Equipment Recommendations

As a manufacturer of mining crushing equipment, we recommend the following equipment to be used in conjunction with the drying process to optimize overall production efficiency:

- Jaw Crusher: Used for primary crushing of raw materials to control the feed particle size.

- Vibrating Screen: Used for classifying materials before and after drying to improve drying uniformity.

- Belt Conveyor: Enables automated material handling between crushing, drying, and storage stages.

Frequently Asked Questions (FAQ)

Q1: Is the rotary dryer suitable for muddy materials with extremely high moisture content?

Yes, but a dewatering or pre-forming process needs to be added at the front end to prevent material from sticking to the cylinder wall. Our company can provide customized loosening devices and lifting plate designs to improve drying efficiency.

Q2: What heat sources can be selected for the equipment?

Common heat sources include natural gas, pulverized coal, steam, and waste heat flue gas. The selection should be based on a comprehensive consideration of local energy prices, environmental requirements, and material characteristics.

Q3: What are the key points to pay attention to during daily maintenance?

It is recommended to regularly check bearing lubrication, gear wear, and seal condition, and clean the dust removal system promptly. Our company provides remote monitoring support and regular inspection services to ensure the long-term stable operation of the equipment.