In numerous industrial sectors such as chemical engineering, metallurgy, building materials, and environmental protection, material drying is a crucial step in the production process. Among various drying equipment, the rotary drum dryer maintains its unshakeable core position due to its superior reliability, powerful processing capacity, and wide material adaptability.

This article will take you on an in-depth exploration of the world of rotary drum dryers, providing a comprehensive understanding of why they have become the preferred solution for large-scale industrial drying.

I. Core Unveiling: How Does a Rotary Drum Dryer Work?

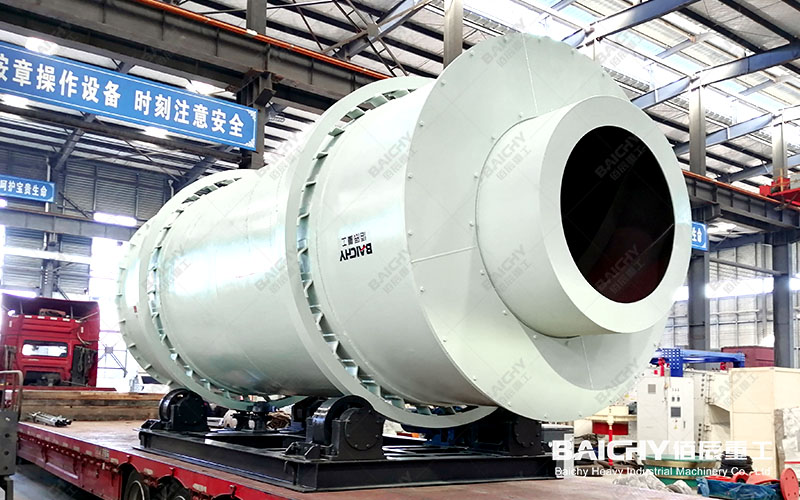

The working principle of a rotary drum dryer is straightforward and efficient. Wet material is continuously fed into the slowly rotating drum from the feed end. The drum is slightly inclined, and under the rotation of the drum and the action of internal lifting plates, the material is continuously lifted and spread to increase its contact area with the heat medium.

Simultaneously, hot air (or hot flue gas) passes through the drum with the material in parallel, counter-current, or cross-flow manner, undergoing thorough heat exchange and causing the moisture in the material to evaporate rapidly. The dried product is discharged from the other end of the drum, thus achieving continuous, large-scale production.

II. Superior Advantages: Why is the Rotary Drum Dryer So Popular?

• High processing capacity: Continuous operation, suitable for drying large quantities of materials.

• High adaptability: By adjusting parameters such as rotation speed, tilt angle, and temperature, it can dry various materials, including granular, powdery, flaky, and even filter cake materials.

• Stable and reliable operation: Robust structure, mature design, able to withstand harsh working conditions, low failure rate, and relatively low maintenance costs.

• High thermal efficiency: Excellent sealing and internal structural design reduce heat loss.

III. Wide range of applications: Which industries rely on it?

Rotary drum dryers are found in various industrial sectors:

• Mining industry: Quartz sand, mineral powder, clay, bentonite, etc.

• Chemical industry: Fertilizers, pesticides, chemical raw materials, polymers, etc.

• Environmental protection industry: Drying treatment of municipal sludge and industrial sludge.

• Agriculture: Feed, bio-organic fertilizer, straw, etc.

• Building materials industry: Sand, gravel, limestone, gypsum, etc.

IV. Key points: How to select the right model?

Choosing the right rotary drum dryer is crucial for project success. Key considerations during selection include:

1. Material characteristics: initial moisture content, final moisture content, particle size, viscosity, heat sensitivity, etc.

2. Production capacity: the amount of material to be processed per hour or per day.

3. Heat source selection: coal, natural gas, steam, oil, or electricity.

4. Environmental requirements: exhaust emission standards; whether dust and odor removal equipment is needed.

As a classic industrial drying technology, the rotary drum dryer remains the preferred choice for many companies due to its proven efficiency. Whether for new projects or upgrading existing lines, a thorough understanding of its principles and applications can help you make more informed decisions and improve production efficiency and economic benefits.