Rock & Aggregate Crushers

Rock and aggregate crushers are indispensable core equipment in modern mining, construction, and infrastructure development. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing global customers with efficient, reliable, and adaptable crushing solutions for all scenarios.

Whether it's hard rock, various ores, or construction aggregates, our crushing equipment can meet the needs of the entire process from coarse crushing, medium crushing to fine crushing with excellent performance and stable output, helping customers improve production efficiency and reduce operating costs.

| Key Words | Rock & Aggregate Crushers |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

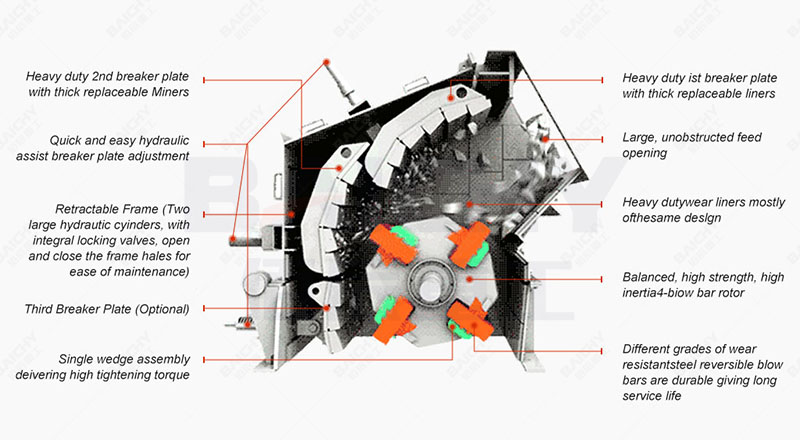

PF Impact Crusher Structure Diagram

Core Product Advantages

1. High Efficiency and Energy Saving, Superior Output: Adopting an advanced crushing chamber design and a high-torque drive system, it achieves a higher crushing ratio and throughput, with output per unit energy consumption significantly exceeding industry standards.

2. Robust and Durable, High Reliability: Core components such as the moving jaw, eccentric shaft, and frame are manufactured using high-strength alloy materials and special processes, possessing excellent wear and impact resistance, resulting in a long equipment lifespan and low failure rate.

3. Intelligent Control, Easy Operation: An integrated advanced automated control system allows for real-time monitoring of equipment operation, enabling remote adjustment, fault diagnosis, and early warning. This significantly reduces reliance on operator experience and ensures safe production.

4. Flexible Adaptability, Full-Scenario Coverage: We offer a variety of models including jaw crushers, cone crushers, impact crushers, and mobile crushing plants. We can customize the optimal crushing production line configuration for customers based on material characteristics, capacity requirements, site conditions (fixed or mobile), and final product particle size.

5. Convenient Maintenance, Economical Costs: User-friendly design makes the inspection and replacement of key components easier and faster, effectively reducing downtime and making overall operating and maintenance costs more competitive in the market.

Wide Application Scenarios

Our crushing equipment and solutions are widely used in the following fields:

• Mining: Crushing and processing of metallic ores such as iron ore, copper ore, gold ore, and bauxite, as well as non-metallic ores such as limestone, granite, and basalt.

• Aggregate Production: Providing high-quality sand and gravel aggregates for infrastructure construction such as buildings, highways, railways, and bridges.

• Construction Waste Recycling: Mobile crushing plants can crush and screen construction waste on-site, achieving resource recycling.

• Quarry: Primary and secondary crushing of various rocks to produce aggregates of different specifications.

PF Impact Crusher Crushing Site

Successful Project Cases

We have provided reliable equipment and services to clients in over 150 countries and regions worldwide.

• A large granite quarry project in Southeast Asia: We equipped it with a three-stage crushing and screening closed-loop system, including a large jaw crusher and a multi-cylinder hydraulic cone crusher, with a capacity of 1500 tons per hour. The finished aggregate has excellent particle shape, fully meeting the needs of the local high-end construction market, and significantly shortening the client's return on investment period.

• African copper mine expansion project: We provided several high-performance heavy-duty cone crushers for processing high-hardness copper ore. The equipment performed stably under harsh operating conditions, ensuring a continuous and efficient supply to the concentrator, and received high praise from the client.

• Middle Eastern Urban Construction Waste Treatment Project: Utilizing our tire-mounted mobile crushing and screening unit, this project achieved flexible relocation and on-site processing within urban areas, handling over one million tons of construction waste annually, resulting in significant environmental and social benefits.

Frequently Asked Questions (FAQ)

Q: How do I choose the right crusher type for my project?

A: The choice depends on various factors, including material hardness, abrasiveness, feed size, required output size, expected capacity, and investment budget. Our technical team can provide free consultation and on-site analysis to recommend the most suitable model and production line configuration for you.

Q: What is the lifespan of the key components of the equipment? Are wear parts readily available?

A: The wear parts of our equipment (such as jaw plates, jaw walls, and hammers) are made of proprietary wear-resistant materials, ensuring a long service life. We have multiple after-sales service centers and spare parts warehouses worldwide, ensuring rapid supply of original equipment parts and maximizing your production continuity.

Q: Can you provide design and installation guidance for the entire production line?

A: Of course. We are not only an equipment manufacturer but also a full-scenario solution provider. We offer turnkey engineering services, encompassing site surveys, process design, equipment selection and configuration, installation and commissioning guidance, and operator training.

Q: Does the equipment meet international safety and environmental standards?

A: All our products strictly adhere to internationally recognized mechanical safety and environmental manufacturing standards, and we provide detailed compliance documentation. The equipment design also fully considers environmental requirements such as dust control and noise reduction.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.