Key Differences Between Jaw Crusher And Impact Crusher

In the field of mining crushing, jaw crushers and impact crushers are two of the most common and critical pieces of equipment, but their working principles, applicable materials, and finished product effects are quite different. As a manufacturer of mining crushing equipment with 20 years of experience, we deeply understand the impact of correct selection on project efficiency, cost, and ultimate returns. This article will delve into the core differences between the two to help you make an informed choice based on your actual needs.

I. Overview of Core Differences

Simply put, jaw crushers represent compression crushing, while impact crushers are the epitome of crushing.

PE jaw crusher

• Jaw Crusher (Tiger Mouth): Employs the principle of compression crushing. The moving jaw plate periodically approaches and moves away from the stationary jaw plate, like two giant jaws clamping and crushing the material. Its robust structure and large processing capacity make it an ideal primary crushing choice for hard, abrasive materials.

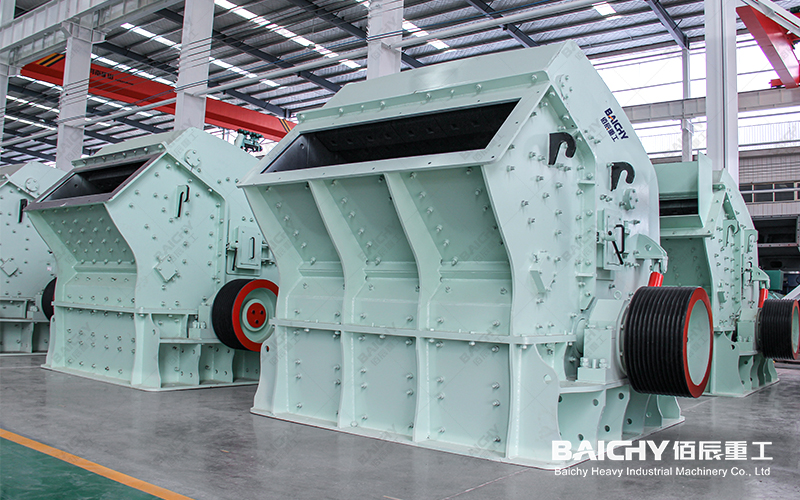

PF Impact Crusher

• Impact Crusher: Employs the principle of high-speed impact crushing. The material is thrown into a high-speed rotating rotor, accelerated by the hammers or throwing heads, and then crushed by impact with the impact plates or by its own collisions within the crushing chamber. Its finished product has excellent particle shape, making it more suitable for medium and fine crushing, used for producing standard-sized stone or manufactured sand.

II. Product Advantage Comparison

Jaw Crusher's core advantages:

1. Robust and durable: Simple structure, heavy-duty body, able to withstand extremely high impact and pressure, especially suitable for processing high-hardness, highly abrasive materials (such as granite and basalt).

2. Wide processing range: Large feed opening, can directly process large blocks of raw stone (up to 1.5 meters or more) mined from the mine, making it the absolute mainstay of primary crushing.

3. Strong adaptability: Low sensitivity to material moisture content, not prone to clogging.

4. Relatively clear maintenance costs: The main wear parts are the jaw plates, replacement and maintenance are relatively straightforward.

Impact Crusher's core advantages:

1. Excellent particle shape: Utilizes impact force for crushing, the finished material is mostly cubic, with low needle-like and flaky content, high quality, especially suitable for high-standard concrete aggregate and manufactured sand production.

2. High Efficiency and Energy Saving: Under suitable operating conditions (medium to low hardness materials), it has a large crushing ratio and excellent energy consumption-output ratio, simplifying the process flow.

3. Flexible Adjustment: By adjusting the rotor speed, impact plate gap, etc., the output particle size can be easily controlled, achieving one machine for multiple uses.

4. Shaping Function: It has a good shaping effect on particles while crushing.

III. Application Scenarios and Selection Recommendations

• Scenarios where jaw crushers are preferred:

◦ Primary Crushing (First Crusher): The first crushing stage for any hard, abrasive ore (metal ore, granite, etc.).

◦ Mobile Crushing Production Line: As the coarse crushing unit of a mobile crushing station, reliability is crucial.

◦ Aggregate production with less stringent particle shape requirements.

• Scenarios where impact crushers are preferred:

◦ Secondary and Tertiary Crushing (Medium and Fine Crushing): Used for further crushing and shaping after the coarse crushing by the jaw crusher.

◦ Manufactured sand and high-quality aggregate production: A high-value-added project with strict requirements for finished product particle shape and gradation.

◦ Processing medium-to-low hardness materials such as limestone and coal gangue: Can be directly used as the main crushing equipment, with a simple and efficient process.

◦ Construction waste recycling: Its impact crushing principle can better separate concrete and reinforcing steel.

Golden rule of selection: In a modern high-performance crushing production line, the two are often the best partners—jaw crushers are responsible for the initial coarse crushing, while impact crushers are responsible for the final fine crushing, forming a highly efficient combined operation.

IV. Global Project Case Studies

1. Southeast Asian Granite Aggregate Project:

◦ Configuration: PE series deep cavity jaw crusher (coarse crushing) + CI series high-power impact crusher (medium crushing) + vertical shaft impact crusher (sand making and shaping).

◦ Results: 500 tons per hour, excellent finished aggregate particle shape, stable manufactured sand modulus, fully meeting the standards of local large-scale infrastructure projects.

2. Iron Ore Crushing Project in Central Asia:

◦ Configuration: Large hydraulic jaw crusher (for processing large ore chunks).

◦ Results: Leveraging its superior wear resistance and high pressure, it stably completes high-intensity primary crushing tasks, providing ideal particle size raw materials for subsequent grinding and beneficiation processes.

3. European Construction Waste Recycling Project:

◦ Configuration: Mobile jaw crusher unit (preliminary decomposition) + mobile impact crusher unit (fine crushing and sorting).

◦ Results: Achieves on-site conversion, producing high-quality recycled aggregates, effectively reducing transportation costs and environmental pressure.

V. Frequently Asked Questions (FAQ)

Q1: Can large ore chunks be directly crushed using an impact crusher?

A: Generally not recommended. The instantaneous impact force of large ore chunks on the rotor and impact components greatly increases wear and the risk of failure. The standard procedure is to first use a jaw crusher for primary crushing.

Q2: Which equipment is more energy-efficient?

A: This depends on the material hardness. For high-hardness materials, jaw crushers typically have lower overall energy consumption. For medium- to low-hardness materials, the high efficiency and large crushing ratio of impact crushers may make them more energy-efficient. Comprehensive material testing and system design are required.

Q3: Which equipment's finished product is more suitable for sand making?

A: Impact crushers, especially vertical shaft impact crushers (sand making machines), are the first choice for professional sand making. Their stone-on-stone and stone-on-iron principles produce high-quality manufactured sand with reasonable gradation and rounded particle shape.

Q4: As a manufacturer with 20 years of experience, how do you help us select the right equipment?

A: We provide a full-scenario solution:

1. Free material testing: Send your material samples to our technical center for crushing tests to obtain key data.

2. Simulation process design: Simulate the optimal equipment configuration based on your capacity, product requirements, and budget.

3. Global case reference: Share similar project experience to help you make decisions.

4. Full lifecycle service: Provide continuous support from installation and commissioning to the supply of wearing parts.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.