Impact Crusher with Various Models

As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing efficient and reliable crushing solutions for the global mining, quarrying, and building materials industries. Impact crushers (also known as sand making machines), as key equipment in modern crushing processes, have become the preferred choice for manufactured sand and high-quality aggregate production due to their unique crushing principle and excellent finished product particle shape.

This article will provide an in-depth analysis of the technical advantages, application scenarios, and practical cases of various impact crusher models, helping you to fully understand this core equipment.

| Key Words | Impact Crusher with Various Models |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Equipment Overview: The Principle and Evolution of High-Efficiency Crushing

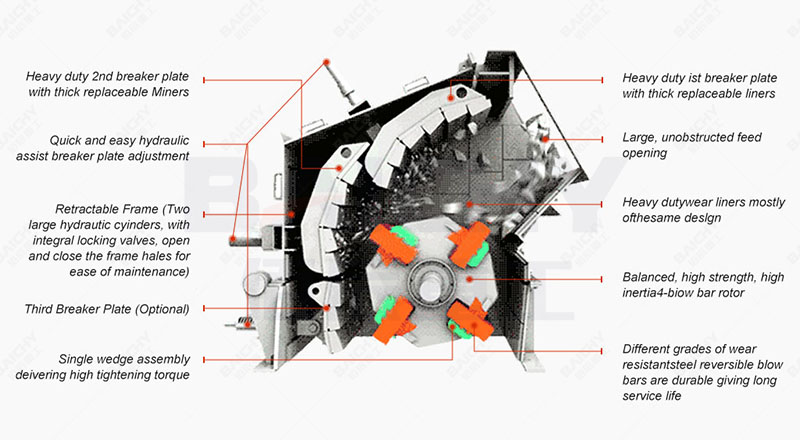

Impact crushers utilize a combination of "stone-on-stone" and "stone-on-iron" working principles. A high-speed rotating impeller accelerates and throws the material, causing it to collide violently with the material lining or impact blocks within the crushing chamber, thereby achieving efficient crushing and shaping of the material. Over the years, the equipment has evolved from the single PCL series to the current mainstream PF AND PEW series. Each series has been deeply optimized for different feed particle sizes, capacity requirements, and finished product specifications, meeting the full range of needs from small and medium-sized sand and gravel plants to large-scale mine aggregate production.

PF Impact Crusher Structure Diagram

Core Advantages of Our Product: Why Choose Our Impact Crusher?

1. Superior Particle Shape and Grading: The unique crushing chamber design and the ability to reverse the crusher after localized wear of the circumferential guard plates ensure excellent particle shape and continuous, stable gradation in the finished sand and gravel, significantly improving the compressive strength and durability of concrete.

2. High Efficiency, Energy Saving, and Low Operating Costs: Optimal discharge port and smooth internal curve design reduce circulating load and increase crushing efficiency by approximately 30%. Core wear-resistant components are made of high-quality alloy materials, ensuring a long service life and significantly lower overall operating costs compared to similar products on the market.

3. Multifunctionality and Flexibility: A versatile machine capable of both sand production and stone shaping. Simple adjustments allow for easy switching between "stone-on-stone" and "stone-on-iron" modes to accommodate different material properties (such as hardness and abrasiveness) and different finished product requirements.

4. Environmental Protection and Intelligent Maintenance: The equipment operates smoothly with low noise. Combined with our dust control solution, it enables green production. Advanced hydraulic opening devices make the inspection and maintenance of core components exceptionally simple, significantly reducing downtime.

Wide Range of Applications

Our impact crusher solutions are widely used in:

• Manufactured sand production: Processing river pebbles, granite, basalt, tailings, etc., into high-quality construction sand that meets national standards.

• High-quality aggregate shaping: Shaping primary aggregates from cone crushers or impact crushers to improve particle shape and increase product added value.

• Mining and metallurgy: Used for fine and ultrafine crushing of various minerals and slags with medium hardness or less.

• Infrastructure construction: Continuously supplying high-quality sand and gravel aggregates for major projects such as highways, high-speed railways, hydropower dams, ports, and airports.

• Construction waste and industrial by-product recycling: Collaborating with mobile crushing plants to achieve resource utilization of construction waste.

PF Impact Crusher Crushing Site

Global Project Case Studies

• A large-scale granite sand production project in Southeast Asia: Utilizing two impact crushers, a high-quality manufactured sand production line with an hourly output of 450 tons was established. The finished sand particles are rounded, with an adjustable fineness modulus, completely replacing natural sand and meeting the stringent local standards for commercial concrete sand.

• Aggregate production for a water conservancy project in East Africa: The project selected an impact crusher as the shaping machine to perform final shaping of primary aggregates. The resulting aggregates had a cubic content exceeding 95%, effectively ensuring the high-quality requirements of the dam concrete.

• A construction waste recycling project in East China: Equipped with a mobile impact crushing station featuring a magnetic separator and lightweight material separation device, demolition waste was successfully converted into renewable aggregates and masonry materials, achieving a win-win situation for both economic and environmental benefits.

Frequently Asked Questions (FAQ)

Q: What are the main differences between an impact crusher, cone crusher, and impact impact crusher?

A: The three operate on different principles. Cone crushers utilize layered crushing, primarily for medium to fine crushing, and are suitable for high-hardness materials. Impact crushers utilize impact energy for crushing, suitable for medium-hard materials, and produce better particle shape. Impact crushers (sand making machines) achieve material collision crushing and self-shaping through high-speed impact, making them specialized equipment for producing high-quality manufactured sand and shaped aggregates.

Q: What is the lifespan of the wear parts of an impact crusher? Is replacement complicated?

A: Our impact crusher's core wear-resistant parts (such as impeller flow channels, peripheral guards, and distribution cones) are manufactured using a special composite process, resulting in a lifespan far exceeding the industry average. The equipment design fully considers ease of maintenance; the hydraulic opening system allows for safe and efficient maintenance, typically requiring only one person to replace major wear parts within a few hours.

Q: Can it handle materials with high moisture content?

A: For materials with high viscosity and high moisture content, we recommend pre-screening, sun-drying, or drying before feeding. Standard-designed impact crushers are more suitable for handling materials with a moisture content below 10%. For special operating conditions, we can provide customized solutions such as heated feed chutes and specially designed liners.

Q: How do I choose the most suitable model for my mine?

A: This depends on your target production capacity, feed particle size and hardness, finished product specifications (especially sand production ratio and particle shape requirements), and investment budget. Our professional engineering team can provide you with free material testing, operating condition surveys, and solution planning, recommending the most cost-effective model and production line configuration.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.