Construction of a 2000 T/D Copper Ore Processing Plant in the Philippines

The Philippines is renowned for its abundant mineral resources, particularly its substantial copper reserves. With the continued growth in global demand for copper, investing in modern copper ore processing plants in the Philippines has become a strategic choice for many mining companies. Among these, a processing plant with a daily capacity of 2,000 tons is a popular choice for medium to large-sized mines due to its good balance between return on investment and operational flexibility. One of the keys to success is choosing an experienced and technically reliable partner for mining crushing and grinding equipment.

What is a 2,000-ton-per-day copper ore processing plant?

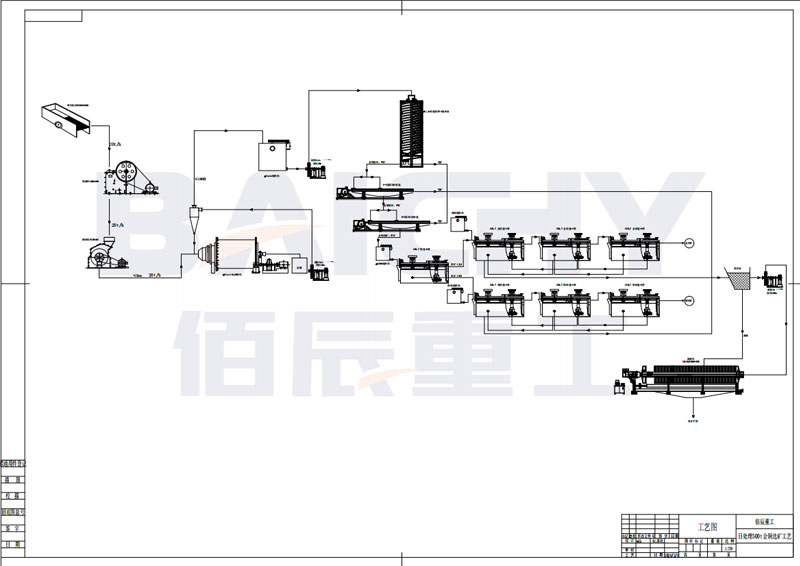

A 2,000-ton-per-day copper ore processing plant is a systematic and continuous industrial production unit. It aims to transform mined raw ore into economically valuable copper concentrate through a series of physical and chemical processes. Its core processes typically include: coarse crushing, medium and fine crushing, grinding, flotation, concentration, and dewatering. For projects of this scale, the stability of the equipment, the smoothness of the process, and overall energy consumption control directly determine the plant's profitability and market competitiveness.

Why choose an equipment manufacturer with 20 years of experience?

As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we deeply understand the needs of projects in environments like the Philippines.

Our value lies not only in providing machines, but also in offering time-tested solutions.

• Deep Process Understanding: We are proficient in the entire process from hard rock crushing to ultrafine grinding, enabling us to provide optimal equipment configurations for your entire mineral processing line.

• Adaptability and Reliability: Designed for the high temperature, high humidity, and rainy climate of parts of the Philippines, as well as the potentially complex ore body properties, our equipment is designed with enhanced environmental adaptability and corrosion resistance in mind, based on material selection.

• One-Stop Service Support: From initial process design and equipment selection to installation, commissioning, operation training, and long-term spare parts supply and maintenance, we provide full lifecycle service to ensure the continuous and stable operation of your plant.

Core Advantages: What do our solutions bring?

1. High Efficiency and High Recovery Rate: Utilizing a multi-stage crushing system with a layered crushing principle, including cone crushers and more efficient ball mills or vertical mills, the system ensures the ore is crushed to the required particle size, creating optimal conditions for subsequent flotation and maximizing copper metal recovery.

2. Low Operating Costs: The equipment is designed for energy conservation, such as optimizing the crushing chamber to reduce power consumption; wearing parts made of highly wear-resistant materials significantly extend replacement cycles, reducing long-term consumable costs.

3. Intelligent Control: The system can integrate advanced automated control systems to monitor equipment status and process parameters in real time, enabling stable, efficient, and minimally staffed operation, particularly suitable for the operating environment in the Philippines.

4. Robust Equipment Reliability: Twenty years of technological accumulation have honed our reliability through rigorous testing. Our equipment is renowned for its robustness and durability, with a long mean time between failures (MTBF), ensuring the successful achievement of your 2000 tons/day processing target.

Successful Case Study: Practical Application of Our Concept

We have successfully delivered a copper mine project of similar scale in Southeast Asia. This project involved complex ore properties (high mud content) and limited site space. We tailored a three-stage crushing solution for them, consisting of a jaw crusher, a single-cylinder hydraulic cone crusher, and a multi-cylinder hydraulic cone crusher, paired with a large energy-saving ball mill and hydrocyclone assembly to form a closed-circuit grinding system. This solution successfully solved the ore clogging problem, achieving a stable daily processing capacity of 2100 tons, with copper concentrate grade and recovery rate exceeding expected targets, earning high praise from the client.

Equipment Recommendation List

For a copper ore processing plant in the Philippines with a daily processing capacity of 2000 tons, we primarily recommend the following equipment combination:

Copper Ore Processing Plant - jaw crusher

• Coarse Crushing Stage: PE series large jaw crusher - a robust primary crushing option.

• Medium and Fine Crushing Stage: HP series multi-cylinder hydraulic cone crusher - achieves efficient layered crushing for medium and fine crushing, resulting in excellent product particle shape.

• Grinding Stage: Grate/overflow ball mill, or emerging vertical mill solutions - flexible selection based on ore fineness requirements.

• Auxiliary Equipment: A complete set of supporting equipment including feeders, vibrating screens, belt conveyors, and dust removal systems.

Frequently Asked Questions (FAQ)

Q1: How long does it typically take from equipment shipment to delivery to the Philippines, and then installation and commissioning?

A: This depends on the specific configuration and site preparation. Generally, after equipment production, shipping to major Philippine ports takes several weeks. On-site installation and commissioning, under the guidance of our engineering team, generally takes 2-4 months. We will develop a detailed project timeline to ensure each step is clear and controllable.

Q2: How well does the equipment adapt to local power fluctuations and voltage conditions in the Philippines?

A: Our electrical systems are designed with the persity of international projects in mind. Key motors and control components are compatible with common Philippine voltage and frequency standards (e.g., 440V, 60Hz). We can also provide voltage stabilization or protection recommendations to ensure stable operation of the equipment under local power grid fluctuations.

Q3: Can your company provide localized after-sales and spare parts support?

A: Yes. We have established a service network and spare parts warehouse in Southeast Asia. We are committed to providing rapid remote technical support and necessary on-site services. For consumable parts, we maintain a safety stock in the Philippines to ensure you have timely access to spare parts when needed, minimizing downtime.

Investing in a modern, efficient copper ore processing plant in the Philippines is a significant decision. Choosing the right equipment partner is the cornerstone of success. We invite you to leverage our 20 years of expertise to help you transform your 2,000-ton-per-day plant blueprint into a sustainable and profitable reality. Please contact our team of experts to begin discussing your specific project needs.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!