PF Series Impact Crusher PF-1007

As a manufacturer of mining crushing equipment with 20 years of professional experience, we deeply understand the crucial role of crushing in mining production. The PF series impact crusher, especially the PF-1007 model, is a prime example of the fusion of our technological expertise and market experience. Designed specifically for the medium-fine crushing of medium-hard materials, it boasts a simple structure, high crushing efficiency, and excellent finished product particle shape, making it a core piece of equipment in numerous sand and gravel aggregate production lines, mining crushing stations, and engineering construction projects worldwide.

| Key Words | PF1007 Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤250mm |

| Motor Power | 45kw |

| Capacity | 15-60t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Advantages: Why Choose PF-1007?

1. High Efficiency and Energy Saving, Low Operating Costs: The PF-1007 employs advanced impact crushing principles. The material gains immense kinetic energy under the high-speed rotating rotor and is crushed upon collision with the impact plate. This combination of "stone-on-stone" and "stone-on-iron" mechanisms achieves a higher crushing ratio and lower energy consumption, with significantly lower power consumption per unit output compared to traditional equipment.

2. Excellent Finished Product Particle Shape, Polyhedral Particles: The crushed material is cubic in shape, with low needle-like and flaky content and no internal cracks. This is crucial for fields with strict requirements on particle shape, such as high-grade building aggregates, highway pavement materials, and high-speed railway ballast, significantly improving concrete strength and project quality.

3. Robust Structure and Easy Maintenance: Key components such as the rotor and impact plates utilize high-chromium wear-resistant materials and a heavy-duty structural design, ensuring high wear resistance and a long service life. A unique hydraulic opening device makes replacing vulnerable parts and routine maintenance exceptionally convenient, greatly reducing downtime.

4. Flexible Application and Strong Adaptability: The PF-1007 can process not only common ores such as limestone, granite, and basalt, but also performs excellently in the production of recycled aggregates from construction waste. Its feed and discharge particle sizes can be flexibly controlled within a certain range by adjusting parameters such as rotor speed and impact plate gap, meeting perse production needs.

5. Environmentally Friendly Design and Green Production: The equipment operates smoothly with low noise. It can be equipped with our dust collection and noise reduction system, easily meeting increasingly stringent environmental production standards and helping customers achieve green mining and sustainable production.

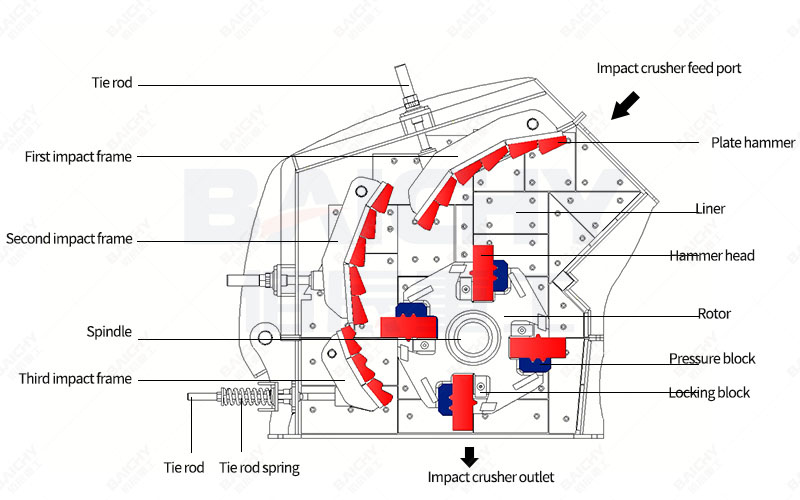

PF Impact Crusher Structure Diagram

Application Scenarios: Comprehensive Crushing Solutions

Leveraging the superior performance of the PF-1007 impact crusher, we can provide global customers with a wide range of comprehensive crushing solutions for various scenarios:

• Fixed aggregate production lines: As the core equipment for secondary or tertiary crushing, used to produce various specifications of commercial concrete aggregates and manufactured sand.

• Mining ore crushing systems: Used for medium and fine crushing of materials from coarse crushers (jaw crushers).

• Construction waste recycling: Crushing demolished concrete, bricks, and tiles to produce recycled aggregates, turning waste into treasure.

• Infrastructure construction: Providing high-quality, stable supply of aggregates for large-scale projects such as highways, railways, water conservancy, and airports.

• Mobile crushing station integration: The PF-1007 can be integrated into our tire-mounted or tracked mobile crushing stations, enabling rapid relocation and localized operation, particularly suitable for decentralized operation scenarios such as urban demolition and small mining sites.

PF Impact Crusher Crushing Site

Project Cases: Global Trust and Testimony

• A large granite quarry project in Southeast Asia: The client's original production line had insufficient capacity and a high rate of flaky finished products. We configured a two-stage closed-loop process consisting of a jaw crusher, a PF-1007 impact crusher, and a vibrating screen. After commissioning, the hourly output stabilized at 80-100 tons, and the finished aggregate had perfect particle shape, meeting the high standards required for key local projects. The client highly praised the reliability of the equipment and our technical services.

• North China Construction Waste Treatment Center: To address the large amount of construction waste generated by urban renewal, we designed a resource recovery production line centered on a mobile crushing station (integrating the PF-1007). The equipment allows for rapid on-site installation, enabling on-site crushing and screening of construction waste. The resulting recycled aggregate is widely used in municipal road subbases, achieving significant economic and social benefits.

FAQ

Q1: What is the maximum feed size for the PF-1007? What is its processing capacity?

A1: The standard maximum feed size for the PF-1007 is approximately 300mm. Its processing capacity varies depending on the material hardness, moisture content, and final product particle size requirements, typically ranging from 30-70 tons/hour. Our engineers will provide a precise capacity assessment based on your specific operating conditions.

Q2: What are the main wear-resistant parts of the equipment? What is the replacement cycle?

A2: The main wear-resistant parts include the rotor's hammer plates, impact liners, and side guards. The replacement cycle depends on the abrasiveness of the material being crushed. For example, when crushing medium-hard limestone, the hammer plates can last for several months or even longer. We provide a complete set of original equipment spare parts to ensure timely supply.

Q3: Can it be used for sand making?

A3: Yes. With appropriate parameter adjustments, the PF-1007 can produce some high-quality manufactured sand (0-5mm). For higher sand production and particle shape optimization, it is recommended to use it in conjunction with our sand making machine (such as a VSI vertical shaft impact crusher) to form a more professional sand making production line.

Q4: Besides providing equipment, do you provide any other services?

A4: Of course. As a full-scenario solution provider, we offer a one-stop service encompassing on-site exploration, process design, equipment manufacturing and supply, installation and commissioning, operation training, and long-term after-sales technical support and spare parts supply. We are committed to becoming your full lifecycle partner for the mining industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.