Impact Crusher Manufacturers | Crushing Experts

In infrastructure construction fields such as mining, building materials, transportation, and water conservancy, high-quality sand and aggregate are the cornerstone of engineering projects. Among numerous crushing equipment, impact crushers (also known as sand making machines), with their unique crushing principle and excellent finished product particle shape, have become the core equipment of modern sand and aggregate production lines, and are hailed as the heart and artist of sand and aggregate production.

As a manufacturer with twenty years of experience in mining crushing and grinding equipment manufacturing, we deeply understand the critical role of impact crushers in increasing production capacity, optimizing finished product quality, and reducing operating costs. This article will delve into its working principle, core advantages, and applicable scenarios.

Impact Crusher PDF, Download ↓↓↓

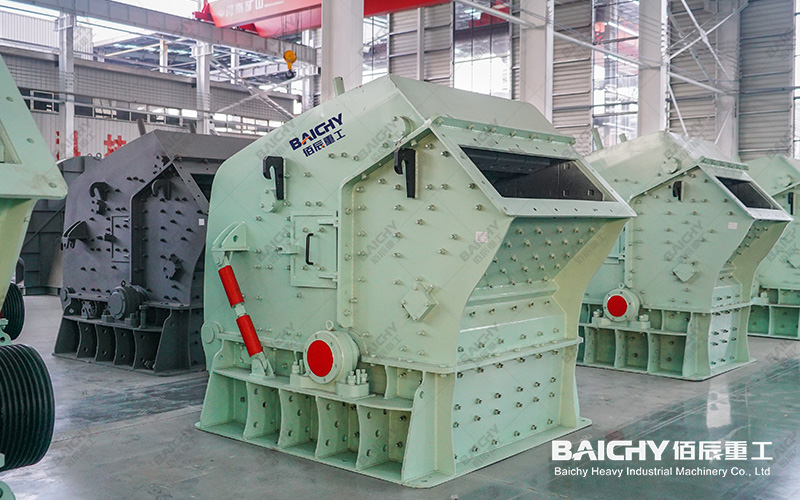

| Product Name | Impact Crushing Machine |

|---|---|

| Brand | Baichy Heavy Industry |

| Place of Origin | Zhengzhou,China |

| Type | Impact Crusher |

| Capacity | 10-400tph |

| Motor Type | AC Motor |

| Motor Power | 45-315Kw |

| Application | Mines and quarries |

| Materials | Ores and hard materials |

| OEM/ODM | Acceptatble |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Customization options | customized on demand,sample processing... |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Working Principle: The Intelligent Collision of Stone-on-Stone and Stone-on-Iron

The impact crusher utilizes two core crushing principles: stone-on-stone and stone-on-iron. Its core working component is a high-speed rotating impeller. Material enters the center of the impeller from the feed hopper, and under the action of high-speed centrifugal force, it is accelerated and thrown out, violently impacting and rubbing against the surrounding naturally formed material lining (stone-on-stone) or the impact blocks on the surrounding protective plate (stone-on-iron), thus achieving efficient crushing and shaping of the material.

This unique self-impact crushing method concentrates equipment wear mainly on the protective layer formed by the material itself, greatly reducing the consumption of wear parts, while ensuring the efficiency and energy saving of the crushing process.

II. Core Advantages: Why is it indispensable?

1. Excellent finished product particle shape and reasonable gradation: Impact crushing causes the material to break along its natural texture and cleavage planes, resulting in mostly cubic particles with extremely low needle-like and flaky content. This gives the finished aggregate higher bulk density and compressive strength, making it an ideal raw material for high-performance concrete.

2. Adjustable fineness modulus, multi-purpose machine: By adjusting parameters such as rotor speed, feed rate, and impact plate gap, the output particle size can be easily controlled, allowing for easy switching between coarse crushing, medium crushing, fine crushing, and sand making modes, achieving one machine for multiple purposes.

3. High crushing efficiency and relatively low energy consumption: The stone-on-stone principle means that energy is primarily used for impact crushing of materials, rather than direct friction with metal components, resulting in high energy utilization and lower energy consumption per unit of product.

4. Shaping and sand-making functions: It's not just a crusher, but also an excellent shaping machine. It is particularly suitable for producing artificial manufactured sand, effectively improving the supply of building materials in areas with shortages of natural sand.

5. Stable operation and easy maintenance: The mature structural design and hydraulic opening device make core inspection and maintenance safer and more convenient. Through twenty years of technological iteration, the reliability and service life of the equipment have been significantly improved.

III. Application Scenarios: Where does it shine?

• High-quality manufactured sand production line: As the core sand-making equipment, it produces construction sand that meets national standards.

• Aggregate processing for commercial concrete mixing plants: Provides coarse and fine aggregates with excellent particle shape and gradation for commercial concrete mixing plants.

• Building materials and refractory materials processing: Used for crushing and shaping various medium-hard materials such as limestone, granite, and basalt.

• Metallurgy and mining beneficiation: Performs fine crushing pretreatment of ores.

• Resource utilization of construction waste: Efficiently crushes and shapes recycled aggregates, increasing the value of recycled materials.

IV. Twenty Years of Experience, Our Commitment and Value-Added Services

Twenty years of dedicated work allows us to provide not only equipment but also system solutions based on our extensive experience:

• Tailor-made selection recommendations: We recommend the most suitable model and configuration based on your material characteristics, production capacity requirements, and finished product standards.

• Long-lasting wear-resistant parts solution: Using high-quality alloy materials and structural optimization, we significantly extend the service life of core wear parts such as impellers and flow plates.

• Intelligent control system: We provide automated control solutions to monitor equipment operating status, provide fault warnings, and ensure stable and efficient operation of the production line.

• Full life cycle service support: From installation and commissioning, operation training to regular inspections and rapid parts supply, we provide a comprehensive after-sales support network.

Conclusion

The impact crusher is a landmark equipment for high-quality, intensive production of sand and aggregate in modern times. Choosing a high-performance, stable impact crusher is the first step to a successful investment. With our twenty years of technological expertise and project experience, we are committed to providing our customers with not just equipment, but also a valuable partnership that guarantees long-term profitability and stable production.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Aggregate crusher equipment

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.