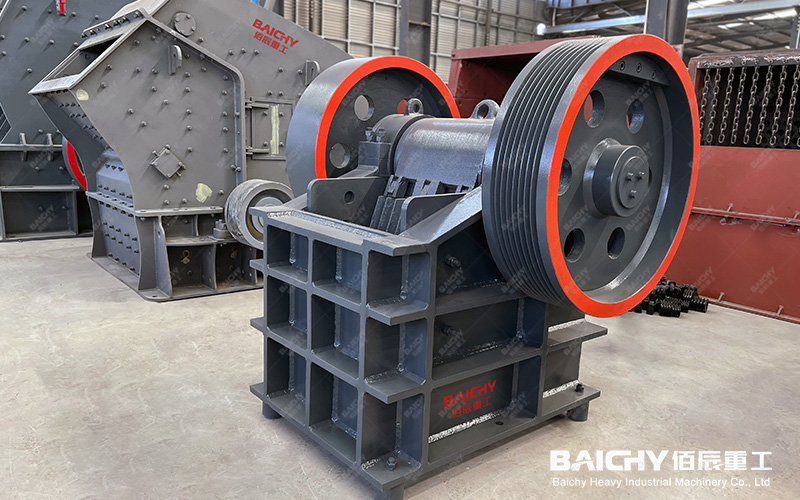

The PE-250×400, PE-400×600, and PE-600×900 models are three classic and common jaw crusher models. Their numbers represent feed opening width (mm) x feed opening length (mm), respectively. These three models have distinct application scenarios, primarily determined by their processing capacity, feed size, and discharge size.

The following are typical application scenarios for each:

1. PE-250×400 Jaw Crusher

This is a representative small jaw crusher model with a relatively small processing capacity.

• Feed opening dimensions: 250mm × 400mm

• Maximum feed size: ~210mm

• Processing capacity: 5-20 tons/hour

• Discharge opening adjustment range: 20-80mm

• Motor power: 15-18.5 kW

Core applications:

• Laboratory crushing: Used in laboratories of scientific research institutions, geology, coal, building materials, and other industries for small-batch coarse or secondary crushing of materials such as ore, rock, and coal.

• Small quarries/stone plants: Suitable for self-employed inpiduals or small engineering projects with low production requirements. Used for crushing limestone, bluestone, construction waste, and other materials to produce bedding material and coarse aggregate.

• Mobile crushing stations: Often used as the main unit of small mobile crushing stations, flexibly used for construction waste recycling and small-scale demolition projects.

• Auxiliary crushing: Occasionally used as pre-processing equipment in large production lines to handle particularly large materials or those that require separate crushing. Summary: The PE-250×400 is suitable for coarse crushing operations requiring low production volumes, small-scale operations, or experimental or high-mobility requirements.

2. PE-400×600 Jaw Crusher

This is the "gold standard" and best-selling model for small and medium-sized jaw crushers, offering excellent value for money and the widest range of applications.

• Feed opening dimensions: 400mm × 600mm

• Maximum feed size: ~340mm

• Processing capacity: 16-60 tons/hour

• Discharge opening adjustment range: 40-100mm

• Motor power: 30-37 kW

Core applications:

• Small and medium-sized sand and gravel aggregate production lines: This is its primary application area. As the primary crushing equipment in a production line, it perfectly crushes materials such as limestone, granite, and river pebbles, providing suitable raw materials for subsequent secondary crushing (cone crusher and impact crusher).

• Mines and Quarries: Suitable for small and medium-sized mining operations, performing the primary crushing of ore.

• Construction Waste Crushing: Processes construction waste such as concrete blocks and bricks, serving as a core piece of equipment in construction waste resource recovery centers.

• Municipal Construction and Highway Maintenance: Used for producing roadbed materials, among other applications.

Summary: The PE-400×600 is the absolute workhorse of small and medium-sized production lines, covering nearly all common coarse crushing applications and making it the most in-demand and versatile model.

3. PE-600×900 Jaw Crusher

This represents the standard medium-sized jaw crusher, offering a step up in both processing capacity and feed size. • Feed opening dimensions: 600mm × 900mm

• Maximum feed size: ~500mm

• Processing capacity: 50-180 tons/hour

• Discharge opening adjustment range: 65-160mm

• Motor power: 55-75 kW

Core application scenarios:

• Medium-to-large sand and gravel aggregate production lines: Serves as standard primary crushing equipment for stone quarries and commercial concrete plants with high production requirements, ensuring a stable supply of large quantities of primary crushed material.

• Medium-sized mines: Used for primary crushing of raw ores from metal mines such as iron, copper, and gold, with sufficient processing capacity to meet the needs of mineral processing plants.

• Large-scale engineering projects: For example, water conservancy and hydropower projects, highway and railway construction, etc., require in-house sand and gravel production lines to ensure material supply. The PE-600×900 is often the preferred primary crushing equipment.

• Stationary crushing station: Typically installed on a fixed production line, serving as the core primary crushing equipment. Summary: The PE-600×900 is suitable for medium-to-large fixed production lines and mining projects with clear output requirements. It is an entry-level and mid-range equipment for large-scale production.

Comparison Summary and Selection Recommendations

| Model | Processing Capacity (tons/hour) | Maximum Feed Size (mm) | Application Scale Core | Application Scenarios |

| PE-250×400 | 5-20 | ~210 | Small | Laboratories, small quarries, mobile crushing, auxiliary operations |

| PE-400×600 | 16-60 | ~340 | Small and medium | Sand and gravel aggregate production lines (absolutely mainstay), construction waste treatment |

| PE-600×900 | 50-180 | ~500 | Medium and large | Medium and large sand and gravel production lines, medium-sized mines, large-scale engineering projects |

How to choose?

1. Determine output requirements: How many tons of raw material do you plan to process per hour? This is the most direct basis for judgment.

2. Determine raw material size: How large is the largest piece of raw material? Ensure smooth access to the jaw crusher's feed port.

3. Consider investment scale: The larger the model, the higher the investment required for the equipment itself and its supporting feeders, motors, and infrastructure.

4. Consider compatibility with subsequent equipment: The primary crusher's discharge particle size must match the feed requirements of the secondary crusher (such as an impact crusher or cone crusher).

For most entry-level or mid-sized users, the PE-400×600 is generally the most reliable and cost-effective choice.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)