A volcanic rock crushing line with a production capacity of 100-150 t/h is operating efficiently in a major infrastructure project in Morocco. With its optimal equipment configuration and advanced process design, this line provides a stable supply of sand and gravel aggregate for local construction, road, and infrastructure development.

Project Background and Production Requirements

Located in northwest Africa, Morocco is rich in volcanic rock resources. This rock, with its high hardness and strong compressive resistance, is ideal for producing high-quality construction aggregates. To meet the growing demand for local infrastructure construction, this line is designed to process 100-150 tons of volcanic rock per hour, producing high-quality crushed stone and manufactured sand in a variety of specifications.

Core Equipment Configuration

This line utilizes a scientifically optimized equipment combination to ensure efficient crushing and screening:

• ZSW9638 vibrating feeder: As the "first checkpoint" of the line, it ensures uniform and continuous material delivery to the crusher, effectively preventing blockages and ensuring stability in subsequent processes. • PE600×900 jaw crusher: Performs primary crushing. Its robust structure and powerful crushing capacity easily handle hard volcanic rock, laying the foundation for subsequent processing.

• DG200 single-cylinder hydraulic cone crusher: Performs secondary crushing. Its compact single-cylinder design and convenient, hydraulically adjustable discharge opening make it particularly suitable for crushing rocks of medium and higher hardness, delivering high production efficiency and excellent finished product particle shape.

• VSI9532 sand making machine (vertical shaft impact crusher): As a key sand-making equipment, it utilizes the "rock-on-rock" and "rock-on-iron" principles to produce machine-made sand with uniform particle size and excellent particle shape, meeting the high-standard requirements for construction sand.

• 3YK1860 vibrating screen and 2YK1860 vibrating screen: Perform screening and grading after secondary crushing and sand making, respectively. The multi-layer screen design allows for simultaneous sorting of finished products in various sizes, such as 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm, ensuring clear, accurate, and efficient product classification.

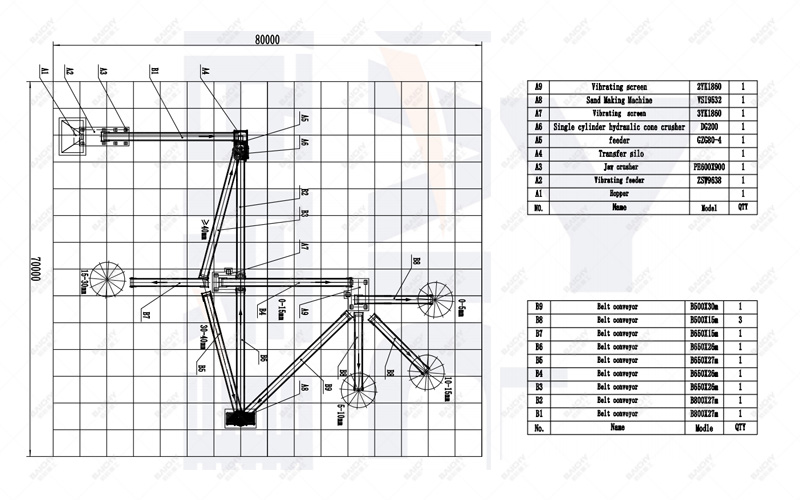

Process Overview

Volcanic rock raw material is first evenly fed by a vibrating feeder into a jaw crusher for primary crushing. The primary crushed material then enters a cone crusher for secondary crushing. The secondary crushed material is screened by a 3YK1860 vibrating screen. The material that meets the specifications proceeds to the next stage, while the oversized particles return to the cone crusher for further crushing. The screened material is processed into machine-made sand in a VSI9532 sand making machine, which is then screened by a 2YK1860 vibrating screen to produce the desired finished products in various sizes.

Project Advantages and Value

This production line features a compact layout and a high degree of automation, which not only reduces operating costs but also significantly improves production efficiency. The finished aggregate has excellent particle shape and a well-balanced gradation, fully meeting the high-standard requirements of local and international building materials in Morocco, providing a solid raw material supply for urban construction, road, and railway projects in Morocco. This production line is not only a successful application of efficient crushing technology but also a model of the perfect combination of Chinese-made equipment and international projects, providing a replicable and scalable solution for areas with similar geological conditions.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)