In the fields of mining, construction aggregate processing, and demolition, crushers are undeniably the heart of the equipment. Faced with project requirements, choosing between a mobile crusher and a stationary crusher is often the primary decision for investors and project managers. As a manufacturer of mining crushing equipment with 20 years of experience in designing, manufacturing, and serving, we understand that both solutions have their advantages and disadvantages, and there is no absolute superiority or inferiority; the key lies in whether they are suitable. This article will delve into the core differences between the two to help you make the wisest investment.

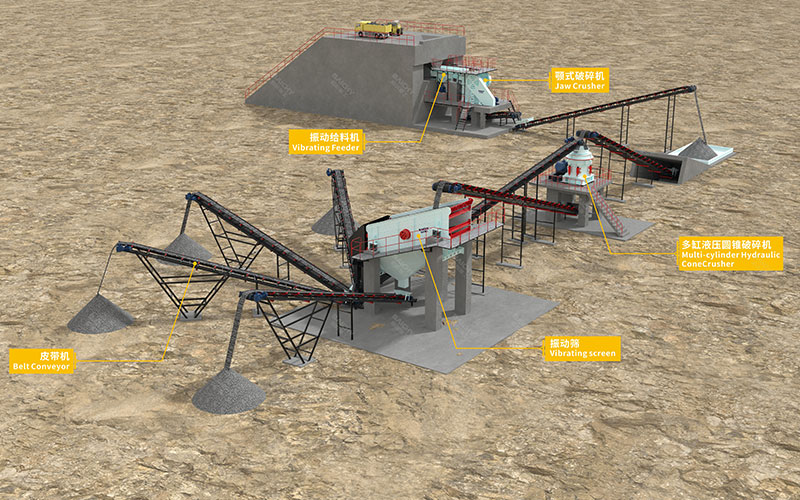

Stationary crushing production line

Mobile crushing production line

Core Difference 1: Flexibility vs. Stability

This is the most fundamental difference between the two, directly determining their application scenarios.

• Mobile Crusher: Its core advantage lies in its high mobility and rapid relocation. It typically uses a vehicle-mounted chassis (tracked or wheeled), allowing for complete movement and even crushing while moving. It is particularly suitable for:

◦ Dispersed, short-cycle engineering projects (such as construction waste disposal, short-term road construction).

◦ Mining operations requiring frequent changes in work locations.

◦ Areas with rugged terrain and weak infrastructure.

• For projects with extremely high requirements for speed of commissioning, start work immediately upon arrival is possible.

• Stationary Crusher: Its core advantages lie in high stability and large processing capacity. The equipment is firmly installed on a concrete foundation, forming a complete production line. It is particularly suitable for:

◦ Long-term, large-scale, centralized raw material processing (such as large stone mines and metal mines).

◦ Aggregate production with strict requirements for product particle shape and gradation.

◦ Permanent production bases with stable power supply and fixed sites.

◦ Projects seeking extremely low unit capacity investment and operating costs.

Core Difference Two: Investment and Operating Costs

The cost structures of the two are drastically different and must be considered from the perspective of the entire life cycle.

• Mobile Crusher:

◦ Initial Investment: Usually higher because it integrates a mobile chassis, control system, etc., resulting in a higher degree of technological integration.

◦ Operating Costs: Fuel costs (diesel) are higher than electricity, but it saves on huge infrastructure construction costs and complex installation and dismantling costs. Its cost advantage lies in the time benefits brought by rapid response. • Stationary Crusher:

◦ Initial Investment: While the equipment itself may be relatively inexpensive, significant additional investment is required for civil engineering foundations, steel structures, long-distance conveyor belts, and complex on-site installation.

◦ Operating Costs: Electricity consumption is low and stable, resulting in a significant cost advantage under long-term, high-intensity continuous operation. However, once the production line layout is determined, modification or relocation costs are extremely high.

Core Difference Three: Production Capacity and Product Form

• Mobile Crusher: Typically has a small to medium processing capacity (although large mobile crushers have emerged in recent years), better suited for handling materials of medium hardness or lower. A single unit can form a closed-loop cycle, but complex processes often require multiple units. The product offers high flexibility, allowing for rapid adjustment of the main unit according to demand.

• Stationary Crusher: Can achieve ultra-large-scale processing capacities ranging from hundreds of tons to tens of thousands of tons per hour. Production lines can be highly customized, easily implementing complex processes such as multi-stage crushing, fine screening, and classified stacking, resulting in more precise and stable control over product particle size and shape.

Key Difference Four: Environmental Protection vs. Intelligent Manufacturing

• Mobile Crusher: Modern models also prioritize environmental protection, equipped with spraying, dust removal, and noise reduction systems. Their intelligent features are reflected in integrated remote monitoring, fault diagnosis, and GPS positioning, facilitating fleet management.

• Stationary Crusher: Due to their fixed installation, they are easier to deploy in fully enclosed plants, centralized dust removal systems, and wastewater recycling systems, offering significant advantages in areas with high environmental standards. They are easily integrated into plant-wide automation control systems (DCS/SCADA) to achieve unmanned or minimally staffed intelligent production.

There is no right or wrong choice, only suitability.

• Choosing a mobile crusher means purchasing a solution and service: you pay for flexibility, speed, and reduced initial site preparation costs. It is suitable for multi-location, short-term projects that are sensitive to the speed of commissioning.

• Choosing a stationary crusher means investing in infrastructure and capacity: you invest in long-term stability, maximum capacity, and minimum operating costs. It is suitable for resource-based enterprises with single-location, long-term, large-scale production.

As an industry partner for 20 years, our advice is: please conduct a comprehensive evaluation based on your material characteristics, project timeline, budget structure, site conditions, and long-term plans. We not only provide two types of reliable equipment, but also offer neutral and professional selection advice, tailoring the most cost-effective production solution for you.