Applications and Advantages of Mobile Sand Making Machines in Peru

With the continued boom in infrastructure construction and mining development in Peru, the demand for high-quality sand and gravel aggregates is increasing. However, Peru's perse terrain and scattered mining areas mean that traditional stationary production lines often face site limitations, high transportation costs, and environmental challenges. Mobile sand making machines, with their unparalleled flexibility, are becoming key equipment for addressing these pain points in the Peruvian market.

| Key Words | Mobile Sand Making Machines |

|---|---|

| Product Model | Tire-mounted mobile sand making machine |

| Capacity | 30-400t/h |

| Core Functions | High-efficiency crushing and shaping of sand making machines (VSI/HVI) |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why are mobile sand making machines needed?

Peruvian mines and construction projects are mostly located in the Andes Mountains or remote areas with complex geographical conditions. Stationary sand making production lines require site leveling, concrete foundation pouring, and the establishment of complex conveyor systems, resulting in large upfront investments and long construction periods. Furthermore, transporting raw materials long distances to fixed processing points or delivering finished products to multiple construction sites incurs extremely high logistics costs.

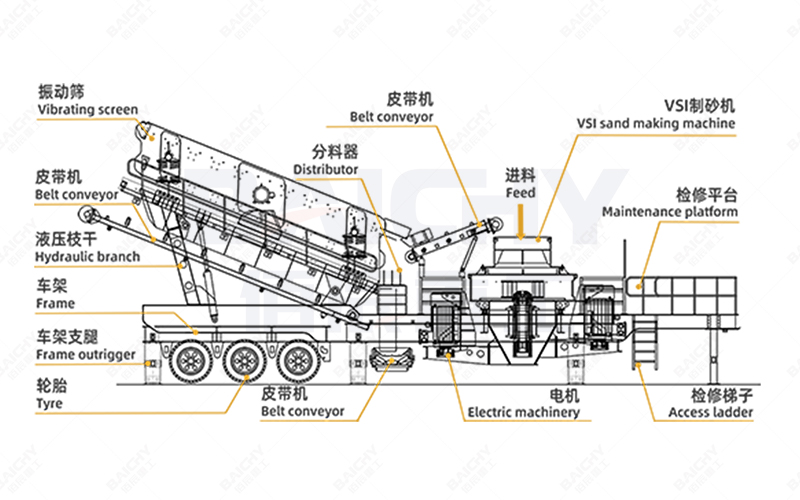

Structural diagram of mobile sand making machine

The essence of a mobile sand making machine is to integrate feeding, crushing, sand making, and screening systems onto one or more mobile vehicle-mounted chassis. This design perfectly meets the needs of the Peruvian market: it can be driven directly to mines or project sites, achieving production where the raw materials are, greatly reducing material transportation costs and dependence on environmental roads.

Mobile Sand Making Machine Overview and Core Advantages

Our mobile sand making machine is not simply a collection of equipment, but a systematic solution designed based on extensive experience.

Core Operating Mode

It typically uses a configuration of jaw crusher + sand making machine or cone crusher + sand making machine. The primary mobile crushing station performs coarse crushing, while the secondary mobile sand making station performs medium and fine crushing and shaping. The two are linked by belt conveyors to form a compact mobile production line.

Key Advantages

1. Extreme Flexibility and Rapid Relocation: The equipment has self-propelled capabilities and remote control operation, allowing for rapid switching between different construction sites or mining locations and immediate production.

2. Significantly Reduced Overall Costs: Eliminating infrastructure construction costs and intermediate transportation links significantly reduces the cost per ton.

3. Adaptability to Complex Terrain and Raw Materials: It can directly penetrate the working face to break up scattered ore bodies inpidually, making it particularly suitable for the mountainous mining areas of Peru.

4. Environmentally Friendly and Rapid Deployment: The equipment offers better noise and dust control, requires no large-scale civil engineering, has minimal environmental impact, and facilitates faster approval and installation.

5. Integrated Intelligent Control: The integrated electrical control system is easy to operate; one person can monitor multiple processes, resulting in a high degree of automation.

Mobile sand making machine granite sand making site

Successful Case Study: Tailings Recycling Project at a Copper Mine in Peru

One of our VSI series mobile sand making machines was successfully applied to a large copper mine in southern Peru. The client wanted to convert accumulated tailings waste into construction sand for use in mine road paving and camp construction.

• Challenges: The tailings pile site was rugged, making fixed production line construction impractical; the raw material hardness was uneven; the project required rapid production.

• Solution: We recommended a tracked mobile sand making station, which drives directly onto the tailings pile to receive the initially screened tailings. The core VSI sand making machine efficiently produces manufactured sand with excellent particle shape through the stone-on-stone and stone-on-iron principles.

• Results: The equipment produced sand within a week of arrival on site, with a reasonable gradation that fully met requirements. This project not only utilized solid waste and created economic value, but also gained recognition from the local government for its flexibility and environmental friendliness. This fully demonstrates the powerful capabilities of mobile sand making machines in comprehensive resource utilization.

Related Equipment Recommendations

In addition to the core mobile sand making machine, an efficient production unit also requires supporting equipment:

• Mobile feeding and screening station: Pre-screens to remove mud and impurities, improving feed quality and protecting the sand making machine.

• Mobile cone crusher station: If the raw material is highly abrasive (e.g., andesite), a mobile cone crusher is recommended for intermediate crushing before connecting to the sand making machine, effectively reducing wear on wear-resistant parts.

• Mobile sand washing machine: If high sand cleanliness is required (e.g., concrete sand), a mobile wheel or spiral sand washing machine can be installed for integrated washing and dewatering.

Frequently Asked Questions (FAQ)

Q1: Is there a difference in sand quality between mobile sand making machines and fixed production lines?

No essential difference. The quality of sand primarily depends on the technical level of the core sand making machine (such as a VSI or vertical shaft impact crusher). Our mobile sand making machine uses the same level of core main unit as the stationary production line, and can also produce high-quality manufactured sand with rounded particle shape and continuous gradation.

Q2: Will the equipment power be affected in the high-altitude mining areas of Peru?

Yes, but we can address this in advance. Some mining areas in Peru are at altitudes exceeding 3000 meters, and the thin air can affect engine power. When configuring equipment, we select turbocharged engines with sufficient power margins and adapted to high-altitude environments, based on the specific altitude of the project site, and adjust the hydraulic and cooling systems to ensure that the equipment remains powerful and operates stably at high altitudes.

Q3: Is the equipment maintenance and spare parts supply convenient in Peru?

We have a comprehensive international service network. We have offices and spare parts warehouses in major mining cities in Peru, enabling us to provide rapid localized technical support and supply of commonly used spare parts. Furthermore, our equipment adopts a modular design, key components are easy to disassemble and assemble, and it is equipped with an intelligent diagnostic system, greatly reducing maintenance difficulty and time.

In Peru, a market brimming with both opportunities and challenges, mobile sand making machines represent a flexible, efficient, and economical new direction for sand and gravel production. It's not just equipment, but an innovative production model. With two decades of technological expertise and a deep understanding of the global market, we are committed to providing our Peruvian customers with the most reliable equipment and the most attentive service, working together to unlock the value of every resource.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!