A Comprehensive Analysis of a 100tph Stone Crushing Production Line in Libya

Against the backdrop of booming global infrastructure construction, the demand for high-quality sand and gravel aggregates is increasing. Recently, we noticed a clear demand from a Libyan customer seeking a complete 100tph (100 tons per hour) stone crushing production line. This reflects not only the urgent need for building materials in Libya but also the market's pursuit of efficient, stable, and ready-to-use industrial production solutions.

As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that a well-designed 100tph production line is the gold standard for many medium-sized quarries and building material projects.

What is a 100tph stone crushing production line?

A complete 100tph (100 tons per hour) stone crushing production line is not simply a collection of machines, but a system engineering project. It aims to transform raw, large stones (such as limestone, granite, and river pebbles) into finished aggregates of various sizes (e.g., 0-5mm, 5-10mm, 10-20mm) through a series of crushing, screening, and conveying processes. These aggregates are widely used in concrete, asphalt, and roadbed construction.

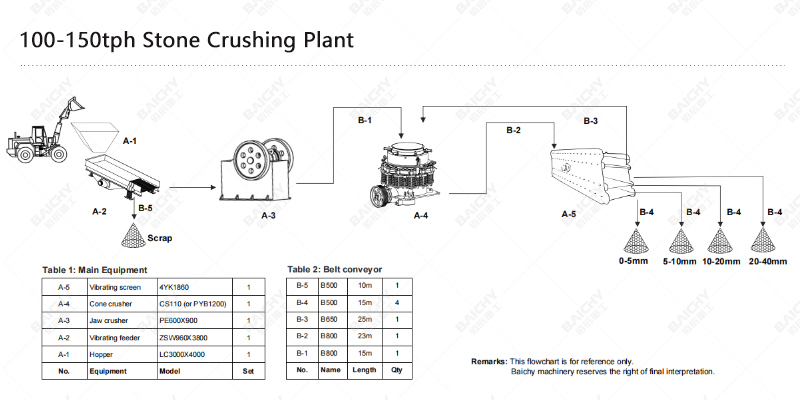

100-150tph rock stone Crushing plant

Core Process Overview

A typical production line flow is: Feeding → Primary Crushing → Secondary Crushing/Medium Crushing → Screening → Finished Product. Stones that do not meet specifications are returned to the crusher via a return system, forming a closed-loop cycle to ensure efficiency and yield.

Core Advantages of Our 100tph Production Line Solution

With 20 years of technological accumulation and global project experience, our solutions designed for Libya and similar markets possess the following outstanding advantages:

Superior Adaptability and Reliability

Libya has a dry and windy climate. We apply special dustproofing treatment to key components of the equipment, such as bearing seals and electrical systems, to ensure high reliability and long service life even in harsh environments, minimizing downtime.

High Cost-Effectiveness and Low Operating Costs

We offer optimized equipment configurations to avoid energy waste caused by over-engineering. Utilizing energy-efficient motors and a rationally designed crushing chamber significantly reduces the production cost per ton of aggregate, delivering long-term return on investment for our clients.

Modular Design and Rapid Delivery

Turnkey projects are our strength. Our production lines feature a modular design with precise component connections, greatly shortening the installation and commissioning cycle on-site in Libya, helping clients quickly launch production and seize market opportunities.

Successful Case Study: Limestone Crushing Project in a North African Country

We successfully delivered and installed a 100-ton-per-hour limestone crushing production line for a North African country with conditions similar to Libya.

• Raw Material: Medium-hardness limestone, feed size ≤ 500mm

• Core Configuration: Vibrating feeder + jaw crusher (coarse crushing) + impact crusher (medium crushing) + circular vibrating screen + belt conveyor system and electrical control cabinet

• Finished Product: Produces three types of best-selling aggregates: 0-5mm, 5-10mm, and 10-20mm

• Customer Feedback: The production line has been running stably for over 3 years, producing excellent particle shape. Equipment maintenance is simple, fully meeting the long-term needs of large-scale local mixing plants, earning the customer a high market reputation.

100tph Complete Stone Crushing Plant

Recommended Standard Configuration for a 100tph Production Line

For common Libyan aggregates (such as limestone), we recommend the following efficient and mature configuration combination:

Configuration Option A: Jaw Crusher + Impact Crusher Combination (Suitable for medium-hardness rock)

This is a classic one-step configuration. The jaw crusher acts as a robust coarse crusher, while the impact crusher performs excellent medium and fine crushing and particle shape optimization. The overall process is simple, with a fast return on investment.

Configuration Option B: Jaw Crusher + Cone Crusher Combination (Suitable for High-Hardness Granite)

If the customer's raw material has high hardness, we recommend a multi-cylinder hydraulic cone crusher with stronger wear resistance as the secondary crushing stage. Although the initial investment is slightly higher, this option has a longer service life for wearing parts, resulting in a more advantageous long-term operating cost.

Frequently Asked Questions (FAQ)

Q1: How long does it take from order placement to production line commissioning in Libya?

A: This depends on the specific configuration. Typically, the production cycle for standard configuration equipment is approximately 45-60 days. Sea freight to major Libyan ports (such as Tripoli) takes approximately 30-40 days. On-site foundation construction can be carried out simultaneously with equipment production. Our experienced engineering team can ensure installation and commissioning are completed within 3-4 weeks after equipment arrival, enabling rapid production.

Q2: Is the production line demanding in terms of electricity? Is a stand-alone generator required?

A: The total power requirement for a standard 100tph production line is typically between 200-300KW. We recommend that customers prioritize connecting to a stable industrial power grid. If the local power supply is unstable, we can calculate the backup generator's power requirements during the solution design phase and provide selection advice to ensure production continuity.

Q3: Can your company provide localized after-sales support and spare parts supply?

A: Of course. We have a long-term network of cooperating agents and service engineers in North Africa. We can provide detailed English/Arabic operation and maintenance manuals and offer remote guidance via online video. For consumable parts, we will provide a suggested spare list with the shipment, and we have a spare parts warehouse in the Middle East, enabling us to quickly respond to critical spare parts supply needs, with air freight typically taking 7-10 days.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!