100 Tph Automatic Grizzly Vibrating Feeder

A stable, efficient, and reliable feeding system is the cornerstone of the smooth operation of the entire crushing and screening process. Today, we will delve into a core piece of equipment highly favored in large-scale mines and aggregate projects—the 100-ton/hour automatic bar screen vibrating feeder.

Why do large production lines need it?

In traditional production line designs, the vibrating feeder and the bar screen are usually two separate pieces of equipment. Material is first conveyed by the feeder and then enters the bar screen for pre-separation. This layout occupies a large area, and transfer points are prone to dust and blockages.

The 100-ton/hour automatic bar screen vibrating feeder innovatively combines the two into one; it is essentially a heavy-duty vibrating feeder with integrated bar screen functionality. Its core mission is to pre-screen fine materials, soil, or materials of suitable particle size that do not need to enter the primary crusher while feeding, thereby reducing the load on the crusher, improving overall system efficiency, and reducing energy consumption and wear.

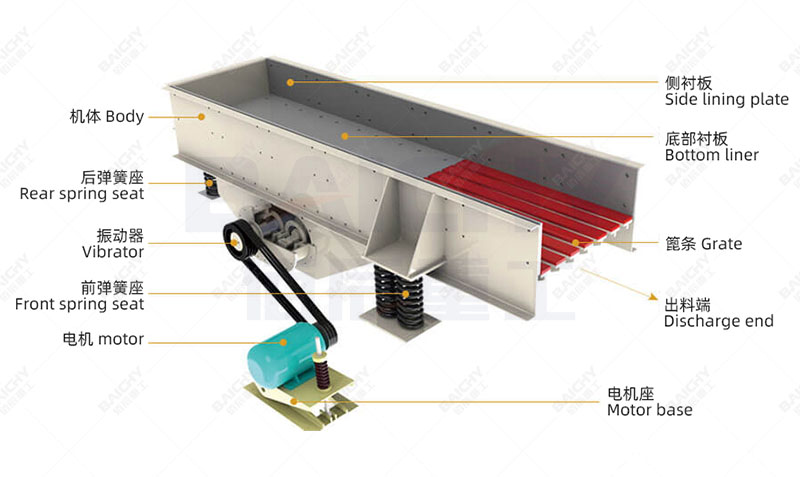

Vibrating feeder structure

Vibrating Feeder Structure and Working Principle

Core Component Analysis

This equipment mainly consists of the following parts:

• Heavy-duty trough: Withstands the impact of large materials, with integrated high-wear-resistant grid bars at the bottom.

• Grid screen: Different gaps (typically 30-150mm) can be selected according to material characteristics (such as particle size, viscosity). Oversize material (large pieces) enters the crusher, while undersize material (fine material) is directly perted.

• Vibrating motor unit: Utilizes dual vibrating motor self-synchronization technology, providing strong and stable linear excitation force to ensure uniform feeding under high throughput.

• Vibration damping spring system: Effectively isolates the equipment from vibration transmission to the foundation structure, resulting in smoother operation.

• Automatic control system: Can integrate frequency conversion control, automatically adjusting the feed rate according to the downstream crusher load, achieving intelligent operation.

Workflow Unveiled

1. Feeding: An excavator or dump truck unloads the raw ore (crude material) into the feeder trough.

2. Synchronized Feeding and Screening: Under strong linear vibration, the material is conveyed forward in a jumping motion along the trough. During this process, material smaller than the grid gap is screened in real time and falls into the fine material conveyor or stockpile below.

3. perted Output: Larger pieces of material on the screen are conveyed to the discharge port at the front of the trough and fed evenly and controllably into coarse crushing equipment such as jaw crushers.

Vibrating feeder outline drawing

Key Advantages of the Equipment: Creating Core Value for Customers

Improved System Efficiency

By pre-screening approximately 10-30% of the fine material, the 100-ton/hour automatic grid vibrating feeder significantly reduces the ineffective load entering the crusher, ensuring the crusher always processes "effective material," resulting in a substantial increase in output per unit time and a reduction in system energy consumption of over 15%.

Reduced Overall Operating Costs

• Crusher Protection: Reduces the filling and wear of the crushing chamber by fine powder materials, extending the life of vulnerable parts such as jaw plates.

• Reduced Blockage Risk: Pre-separates sticky mud and fine materials, avoiding blockages at the crusher discharge port and downstream conveyors. • Cost Savings: This dual-purpose machine saves on the purchase cost and installation space of a separate grid screen.

Stable and Intelligent Operation:

The robust heavy-duty structural design ensures reliability during continuous operation at 100 tons/hour or even higher throughput. Combined with an automatic control system, it achieves "on-demand feeding," keeping the entire primary crushing section operating at its optimal state and reducing manual intervention.

Vibrating feeder on-site operation diagram

Success Story Sharing:

In a large granite aggregate production line project in East China, we configured this 100-ton/hour automatic grid vibrating feeder for our client. The raw material had a high mud content and uneven particle size. After the equipment was put into operation:

• Successfully separated mud and fine materials (approximately 25% of the total) with a particle size smaller than 40mm in advance.

• Allowed the downstream jaw crusher to fully utilize its actual processing capacity, resulting in a stable overall production line output exceeding the design value.

• Client feedback indicated that the wear cycle of the crusher jaw plates was extended by approximately 30%, resulting in substantial annual savings in wear parts costs and electricity bills.

Recommended Equipment

To fully utilize the efficiency of the 100 ton/hour automatic bar vibrating feeder, we recommend combining it with the following equipment to form a optimal coarse crushing system:

• PE series deep cavity jaw crusher: As the main coarse crusher, it handles large pieces of material after screening by the feeder, offering strong crushing force and matching output.

• Heavy-duty plate feeder: Suitable for extra-large pieces and high-drop conditions, serving as a front-end buffer for the vibrating feeder, protecting it from direct impact.

• Belt conveyor system: Used to receive oversize and undersize materials, achieving efficient material transfer.

Frequently Asked Questions (FAQ)

1. Is the processing capacity "100 tons/hour" a fixed value?

Not entirely. 100 tons/hour is the standard design capacity. Actual processing capacity will be affected by factors such as material density, particle size distribution, moisture content, and installation angle. 1. By adjusting the excitation force of the vibratory motor (e.g., frequency converter control), the speed can be intelligently adjusted within a certain range (e.g., 80-120 tons/hour) to adapt to production needs.

2. Can the grid gap be adjusted or replaced?

Yes. The grid bars are usually designed modularly, allowing for quick replacement according to different material characteristics and process requirements (e.g., the particle size to be separated). The gap size needs to be determined based on your raw material at the time of ordering.

3. Is equipment maintenance complex?

Daily maintenance is very simple. The main tasks are to periodically check the tightness of the vibratory motor bolts, whether the springs are broken, and the wear of the grid bars. The equipment uses centralized lubrication points for convenient lubrication. The robust design ensures a very low failure rate.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!