Belt Conveyor

In mining and mobile crushing operations, efficiency and safety are core to profitability. Mining belt conveyor systems are the "main arteries" connecting critical stages such as crushing, screening, and storage, determining the smoothness of the entire material handling process. As a professional manufacturer of mobile crushing equipment for mining, we understand the importance of a reliable and efficient conveyor system in improving overall production efficiency. This article will delve into mining belt conveyor systems, discussing their advantages, applications, and how they perfectly integrate with mobile crushing plants.

System Overview: More Than Just "A Belt"

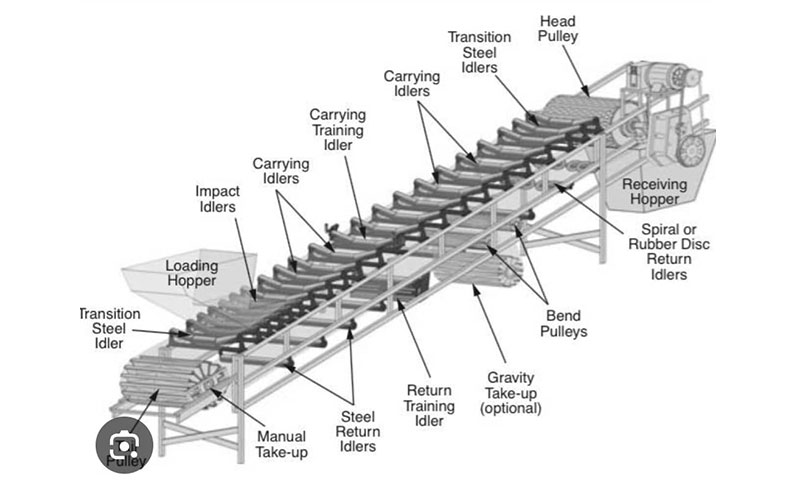

A complete mining belt conveyor system is far more than just the conveyor belt itself. It is an integrated engineering system, primarily including:

Conveyor belt: The core component that carries the material; its material, width, and strength are designed according to the material characteristics.

Driving device: Provides power, usually including a motor, gearbox, and drive pulley.

Idlers and supports: Support the conveyor belt and material, reducing running resistance.

Tensioning device: Maintains sufficient tension in the conveyor belt to ensure effective transmission.

Cleaners: Remove material adhering to the return belt, protecting the pulleys and idlers.

Safety devices: Including anti-deviation, anti-tear, and emergency stop switches to ensure safe operation.

Why Choose a Professional-Grade Mining Belt Conveyor? Analysis of Core Advantages

Compared to general-purpose conveying equipment, belt conveyor systems specifically designed for mining have irreplaceable advantages:

Excellent Reliability and Durability

Mining environments are harsh, and materials are abrasive and subject to high impact forces. Professional systems utilize heavy-duty structures, wear-resistant materials, and reinforced components, capable of continuously withstanding high-load impacts 24/7, minimizing unexpected downtime and ensuring production continuity.

Extremely High Conveying Efficiency and Economy

Belt conveyors can achieve large-scale, long-distance, and continuous material transportation, with significantly lower energy consumption per unit than intermittent transportation methods such as trucks. In mining applications, they can stably and quickly transport materials after primary crushing to secondary crushing plants or stockpiles, significantly reducing overall operating costs.

Excellent Flexibility and Environmental Friendliness

Especially the mobile or retractable belt conveyors, when paired with mobile crushing plants, can be quickly relocated as the mining face advances, forming a flexible and continuous operation line. At the same time, the fully enclosed design effectively suppresses dust and reduces noise, meeting strict environmental protection requirements.

| Belt width (mm) |

Conveying length (m)

Power (kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

| 500 |

≤ 12/3 |

≤ 12-20/4-5.5 |

≤ 20-30/5.5-7.5 |

1.3-1.6 |

40-100 |

| 650 |

≤ 12/4 |

≤ 12-20/5.5 |

≤ 20-30/7.5-11 |

1.3-1.6 |

80-120 |

| 800 |

≤ 10/4 |

≤ 10-15/5.5 |

≤ 15-30/7.5-15 |

1.3-1.6 |

120-200 |

| 1000 |

≤ 10/5.5 |

≤ 10-20/7.5-11 |

≤ 20-40/11-22 |

1.3-2.0 |

200-320 |

| 1200 |

≤ 10/7.5 |

≤ 10-20/11 |

≤ 20-40/15-30 |

1.3-2.0 |

300-500 |

Synergistic Operation: The Golden Combination of Conveyors and Mobile Crushing Plants

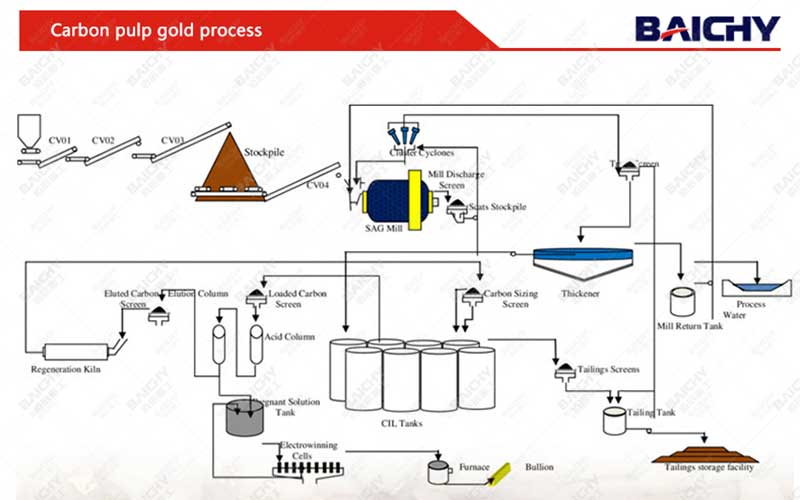

In our project experience, the integration of mining belt conveyor systems with mobile crushing equipment is key to success. For example, in a large limestone mine, the customer adopted our "crawler mobile jaw crusher + mobile transfer conveyor + long-distance fixed belt conveyor" solution.

Case Summary: The mobile jaw crusher performs primary crushing at the mining site, and the connected mobile transfer conveyor adjusts the discharge height and position, accurately feeding the crushed material into a 1.5-kilometer-long fixed belt conveyor, which directly transports it to the processing plant several kilometers away.

Results: Completely replaced traditional truck transportation, increasing transportation efficiency by over 40%, eliminating fuel costs and tire wear, significantly reducing on-site dust and noise, and significantly shortening the return on investment period.

Mobile Jaw Crusher

How to Choose the Right System? Our Professional Recommendations

Choosing a mining belt conveyor system requires comprehensive consideration of:

Material characteristics: including particle size, bulk density, moisture content, and abrasiveness.

Process requirements: conveying capacity (tons/hour), conveying distance, and lifting height.

Mobility requirements: fixed, semi-mobile, or fully mobile?

Environmental conditions: terrain, climate, and environmental regulations.

We recommend early communication with your equipment manufacturer (such as us). Based on the discharge characteristics, output, and overall layout of your crushing equipment, we can design or recommend a matching conveying system solution for you, achieving integrated optimization of "crushing-conveying" and avoiding blockages, spillage, or efficiency bottlenecks caused by improper interfaces.

Frequently Asked Questions about Mining Belt Conveyor Systems (FAQ)

FAQ 1: How long are the conveyors typically equipped with mobile crushing plants?

This depends on the specific model and design. Typically, the main discharge belt length of a crawler mobile crushing plant is between 8-15 meters to ensure sufficient discharge distance and height. More importantly, we will configure an independent mobile yard conveyor (up to 20-30 meters in length) to connect with it, forming a flexible material transfer system.

FAQ 2: How does the conveyor system cope with extremely harsh weather and dust?

The professional system is equipped with fully enclosed protective covers, effectively preventing wind and rain and suppressing dust spillage. Key bearing parts use multiple seals. For sticky and wet materials, high-efficiency self-cleaning rollers and multiple scraper cleaners are used to prevent material adhesion and belt slippage.

FAQ 3: What are the key maintenance points of the system? How to perform daily maintenance?

The core of daily maintenance is "cleaning and inspection": regularly clean accumulated materials (especially on the return side), check whether the idler rollers rotate smoothly, and check whether the belt is misaligned or worn. The key maintenance areas are the lubrication of the drive roller bearings, the adjustment of the tensioning device, and the wear of the scraper blades. It is recommended to develop a preventive maintenance plan and execute it according to the plan.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!