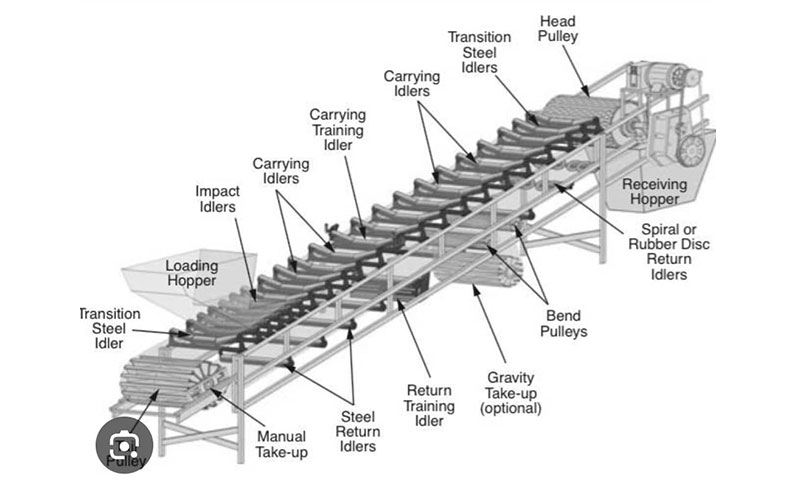

Belt Conveyor

In mining material handling systems, belt conveyors are not just simple transportation equipment, but the "main artery" of the entire production process. As a professional manufacturer of mobile crushing equipment for mining, we deeply understand that choosing the right mining belt conveyor supplier and manufacturer directly impacts the efficiency, reliability, and operating costs of the entire crushing production line. This guide will help you understand how to choose a truly professional partner.

Key Differences Between Professional and Ordinary Suppliers

There are significant differences between mining belt conveyor suppliers and ordinary conveyor equipment suppliers. Professional suppliers should possess the following characteristics:

Deep Understanding of Mining Conditions

Professional mining belt conveyor manufacturers not only produce conveying equipment but also understand the special conditions of mining operations:

High impact loads: Able to withstand the impact of large chunks of ore

Harsh environments: Adaptable to dust, humidity, and temperature fluctuations

Continuous operation: 24/7 reliability requirements

Mobility requirements: Coordination with mobile crushing plants

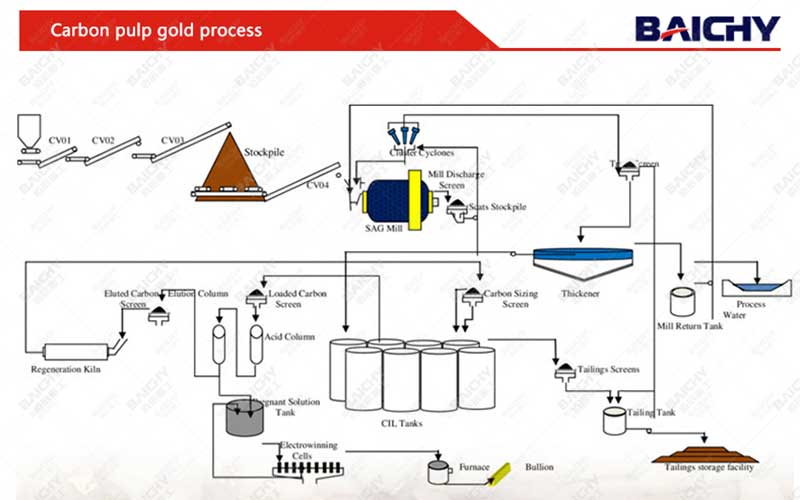

Integrated Solution Capabilities

Excellent mining belt conveyor suppliers should be able to provide:

Perfect interface design with crushing equipment

Complete system planning from feeding to stockpiling

Electrical control and automation integration

Dust control and safety protection devices

Installation guidance and commissioning services

Customized Design and Engineering Support

Unlike standardized product suppliers, professional manufacturers provide:

Customized design based on material characteristics

Terrain-adaptive layout planning

Load calculation and power configuration optimization

Structural strength and durability design

Consideration for ease of maintenance

Our Professional Advantages: From Crusher Manufacturer to Conveying System Expert

As a manufacturer proficient in both mobile crushing equipment and mining belt conveyors, we offer unique value:

Seamless System Integration Advantages

We have a deep understanding of the crushing process, ensuring that the conveying system perfectly matches the crushing equipment:

Precise alignment of discharge ports and receiving points

Coordination of processing capacity and crushing output

Optimization of material characteristics and conveying parameters

Integrated control system design

Quality and Durability Assurance

Our mining belt conveyors feature:

Heavy-duty structural design to suit mining conditions

High-quality components for extended service life

Wear-resistant and tear-resistant special treatment

Strict quality control system

Complete testing and verification process

Full Lifecycle Service Support

From belt conveyor manufacturer to long-term partner:

Preliminary technical consultation and solution design

Professional installation guidance and commissioning

Operation and maintenance training

Spare parts supply guarantee

Technical upgrade and modification support

| Belt width (mm) |

Conveying length (m)

Power (kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

| 500 |

≤ 12/3 |

≤ 12-20/4-5.5 |

≤ 20-30/5.5-7.5 |

1.3-1.6 |

40-100 |

| 650 |

≤ 12/4 |

≤ 12-20/5.5 |

≤ 20-30/7.5-11 |

1.3-1.6 |

80-120 |

| 800 |

≤ 10/4 |

≤ 10-15/5.5 |

≤ 15-30/7.5-15 |

1.3-1.6 |

120-200 |

| 1000 |

≤ 10/5.5 |

≤ 10-20/7.5-11 |

≤ 20-40/11-22 |

1.3-2.0 |

200-320 |

| 1200 |

≤ 10/7.5 |

≤ 10-20/11 |

≤ 20-40/15-30 |

1.3-2.0 |

300-500 |

Success Story: The Practical Value of Integrated Solutions

In a large iron ore project in Inner Mongolia, the client initially purchased mobile crushing stations and conveyor systems separately, but encountered serious problems:

Challenges:

Mismatched interfaces leading to frequent material blockages

Incompatible control systems

Unclear maintenance responsibilities

Low overall efficiency

Our Solution:

As a professional manufacturer of mobile crushing equipment and mining belt conveyors, we provided:

Redesign of the entire material handling system

Replacement with matching conveyor equipment

Implementation of a unified control system

Provision of an integrated maintenance plan

Results:

System efficiency increased by 35%

Maintenance costs reduced by 40%

Downtime reduced by 60%

Return on investment period shortened to 18 months

How to Choose the Right Partner: Our Professional Advice

When choosing a mining belt conveyor supplier, consider the following factors:

Matching Professional Experience

Do they have experience with similar mining projects?

Do they understand your specific material characteristics?

Can they provide industry references?

Technical Capability Assessment

Design capabilities: Can they provide customized solutions?

Manufacturing capabilities: What is their quality control system like?

Integration capabilities: Experience in coordinating with crushing equipment?

Service Support System

Installation and commissioning support

Training services

Spare parts supply

Emergency response capabilities

Long-term Partnership Value

Technical support and upgrades

Technical training updates

System optimization suggestions

Long-term partnership relationship

Frequently Asked Questions (FAQ)

FAQ 1: Why choose a partner that is both a crusher manufacturer and a conveyor supplier?

Choosing a supplier that is proficient in both types of equipment ensures optimal system integration. We understand the material changes, impact characteristics, and capacity fluctuations during the crushing process, and can design a perfectly matched conveyor system, avoiding common problems such as interface issues, capacity mismatches, and control inconsistencies, thus achieving higher overall efficiency.

FAQ 2: What is the difference between a professional mining belt conveyor manufacturer and an ordinary manufacturer?

The main differences are reflected in: 1) Structural strength: Professional products adopt heavy-duty design to withstand higher impacts; 2) Material selection: Using more wear-resistant and corrosion-resistant materials; 3) Detailed design: Such as anti-deviation, anti-spillage, and easy maintenance features; 4) Safety features: Complying with mining safety standards; 5) Environmental adaptability: Adapting to harsh working conditions in mines.

FAQ 3: How to ensure the quality of the conveying system with a limited budget?

Suggestions: 1) Clearly define key requirements, distinguishing between essential and optional functions; 2) Choose a modular design for easy future expansion; 3) Focus on total cost of ownership rather than just the purchase price; 4) Prioritize the quality of critical components; 5) Consider the possibility of phased implementation. A professional mining belt conveyor supplier can help you make the best choice within your budget.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!