Complete Guide to CIP Cleaning and Processing Equipment | Mining Equipment Manufacturer

For any company involved in mining, especially those dealing with chemical beneficiation (such as the extraction of precious metals like gold, silver, and copper), a complete CIP (Carbon-in-Pulp) processing system is not only a part of the production line but also the core of ensuring efficiency, recovery rate, and environmental compliance. As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand the importance of seamless integration of upstream and downstream processes. Today, we will delve into CIP equipment and explain why it is an indispensable component of modern mineral processing plants.

I. Overview of CIP Technology: What is "Carbon-in-Pulp"?

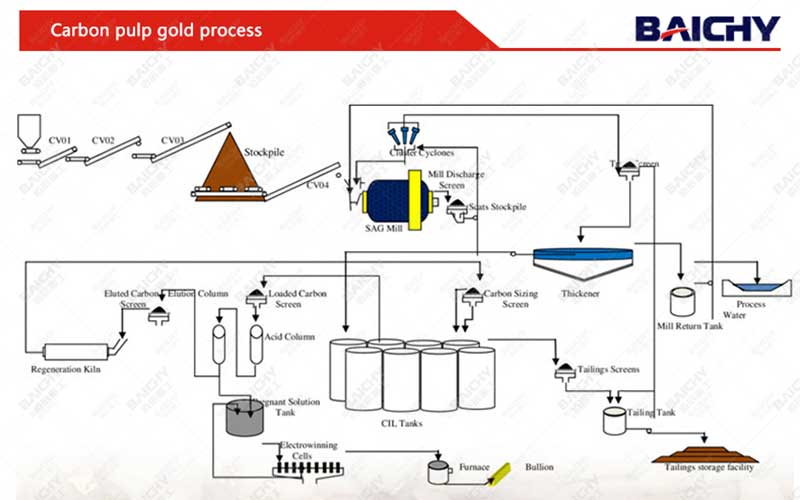

CIP, short for Carbon In Pulp, is a mature process for extracting precious metals such as gold from cyanide pulp. Its core principle is to utilize the strong adsorption capacity of activated carbon to adsorb gold from the leached gold-bearing solution, and then obtain high-purity gold mud or gold ingots through desorption, electrolysis, and other steps.

Key Process Flow Analysis

A complete CIP processing system is far more than just a few tanks containing activated carbon. It is an integrated system, mainly including:

• Adsorption Tank Series: Multiple stirred adsorption tanks in series ensure sufficient contact between the pulp and activated carbon, maximizing gold adsorption.

• Carbon Screening and Transfer System: High-efficiency vibrating screens separate the gold-bearing carbon from the tailings pulp, and a pneumatic or pumping system is used to transfer the carbon in the reverse direction.

• Desorption and Electrolysis System: Under high temperature and pressure conditions, the gold on the gold-bearing carbon is desorbed into the pregnant solution, and then solid gold is obtained through electrolytic deposition.

• Acid Washing and Regeneration System: The depleted carbon after desorption is activated and regenerated to restore its adsorption capacity for reuse, significantly reducing costs.

Complete Guide to CIP Cleaning and Processing Equipment

II. Why Choose an Integrated CIP Processing System?

As an equipment manufacturer, we advocate providing customers with integrated, turnkey solutions rather than fragmented components. This advantage is particularly significant for customers in resource-rich regions such as Tanzania.

Core Advantages of Integrated Solutions

1. Maximized Efficiency: Each subsystem (adsorption, screening, desorption) is precisely calculated and matched, avoiding the "bottleneck effect" and ensuring overall recovery rate (usually >98%) and throughput.

2. Optimized Operating Costs: An efficient carbon regeneration system reduces the amount of activated carbon required; automated control reduces reliance on manual labor and minimizes operational errors; and optimized engineering design reduces power and reagent consumption.

3. Faster Delivery and Commissioning: We provide a complete service package, from basic design and equipment manufacturing to on-site installation guidance, commissioning, and training. Clients do not need to deal with multiple suppliers, ensuring clear responsibilities and a more controllable project timeline.

4. Long-Term Service Guarantee: Based on 20 years of experience in heavy-duty mining equipment manufacturing, our equipment is known for its robustness and durability. We provide continuous spare parts supply, remote technical support, and regular maintenance services to eliminate your worries.

III. Success Story: Creating Value for a Tanzanian Client

We provided a complete CIP adsorption plant project with a daily processing capacity of 800 tons for a medium-sized gold mine in Tanzania.

• Client Pain Points: The original process used the traditional zinc powder displacement method, resulting in unstable gold recovery rates (approximately 92%), high operating costs, and safety hazards.

• Our Solution: We designed and delivered a complete CIP workshop including a 6-stage adsorption tank, a high-efficiency desorption and electrolysis unit, and a carbon regeneration system.

• Achieved Results: After the new system was put into operation, the total gold recovery rate increased to over 98.5%, the annual consumption of activated carbon decreased by 40%, and the production process became safer and more environmentally friendly. This project has become a model for mining industry upgrades and transformations in the region.

IV. Related Equipment Recommendations: Full-Chain Support from Crushing to Mineral Processing

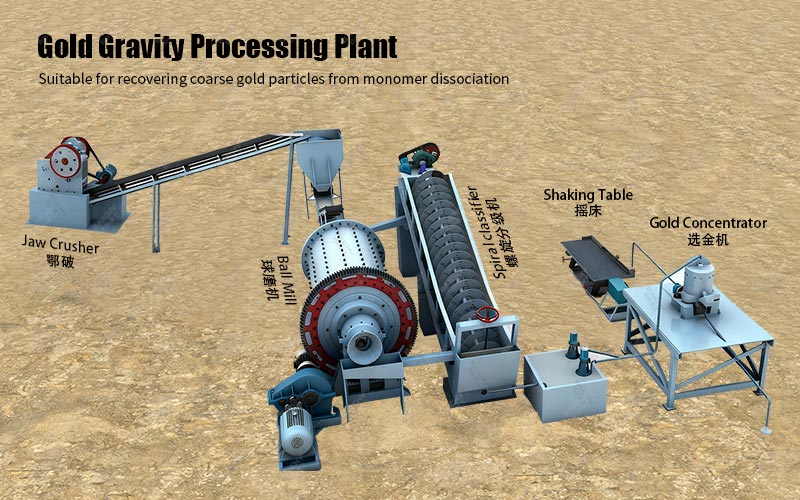

CIP is the "back-end refining" stage of mineral processing. To maximize its efficiency, the quality of crushing and grinding at the front end is crucial. Coarse particle size leads to insufficient gold exposure, directly affecting the leaching rate and the final CIP recovery rate.

• We can provide complete crushing and grinding solutions, from jaw crushers and cone crushers to ball mills and classifiers, ensuring that the CIP system is supplied with mineral slurry of the correct particle size and sufficient liberation.

• For different ore properties (such as clay content, degree of oxidation, etc.), we can design targeted crushing, grinding, and pre-treatment processes to lay the foundation for the efficient operation of the CIP system.

V. Frequently Asked Questions (FAQ)

1. What are the specific requirements of the CIP process regarding ore properties?

The CIP process is best suited for treating dissociated, cyanide-leached gold-bearing slurries. It is somewhat sensitive to the clay and organic matter content of the ore. In the early stages of a project, we strongly recommend conducting detailed ore amenability tests to determine the optimal grinding fineness, leaching parameters, and carbon adsorption process.

2. What are the key investment and operating cost components of a complete CIP system?

Key investments mainly include: adsorption tanks, carbon screens, desorption and electrolysis columns, heating systems, control systems, and plant infrastructure. Operating costs mainly come from activated carbon (consumption and replenishment), electricity (mixing, heating, transportation), reagents (cyanide, NaOH, etc.), and labor for maintenance. Our design solutions will help you effectively control long-term operating costs by optimizing energy efficiency and carbon recycling rates.

3. What are the main differences and advantages of CIP compared to the CIL (Carbon-in-Leach) process?

CIP is "leaching followed by adsorption," meaning the slurry completes the cyanidation reaction in separate leaching tanks before entering the CIP system for adsorption. CIL is "leaching and adsorption simultaneously." The advantage of CIP lies in more precise process control, especially suitable for slurries with higher gold grades or complex ore properties (such as those containing many gold-robbing substances). It prevents premature poisoning of activated carbon and allows for independent optimization of leaching conditions, usually resulting in higher final recovery rates.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!