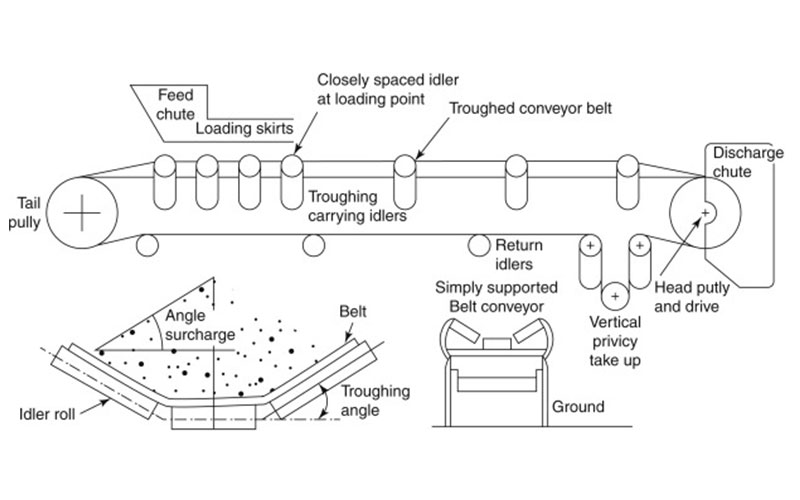

Belt Conveyor

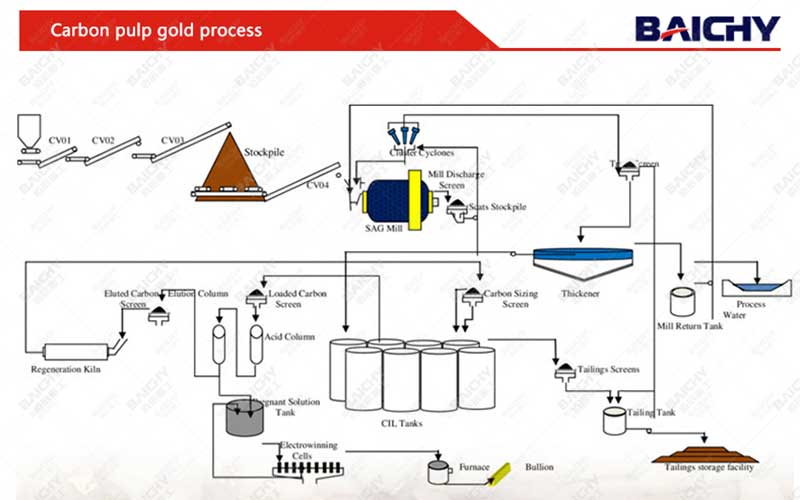

In the field of manufactured sand production, while the sand crusher is undoubtedly the core of a sand crushing plant, it is often the conveying system that determines whether the entire production line operates smoothly, efficiently, and stably. Conveyors act as the "vascular network" of the production line, responsible for accurately and continuously transporting raw materials, semi-finished products, and finished sand aggregates of various particle sizes to each processing unit. A poorly designed conveying system can lead to blockages, dust generation, high wear, and frequent downtime, directly impacting profitability. This article will delve into the critical role and selection considerations of conveyors specifically designed for sand crushing plants.

Overview: Precision Logistics Beyond Ordinary Conveying

Material handling in a sand crushing plant is far more than simple "transportation." It involves multiple materials (large stones, medium aggregates, crushed stone, manufactured sand, stone powder), multiple process points (feeding, primary crushing, secondary crushing, sand making, screening, return material, finished product classification), and demanding operating conditions (high wear, high dust, continuous operation). Therefore, a sand crushing plant's conveying system requires a precisely calculated logistics solution, aiming to ensure materials arrive at the right place at the right time and at the right speed, ensuring a seamless connection throughout the entire sand and aggregate production ecosystem.

Challenges in Sand Production Line Conveying

Material Diversity: From raw materials several tens of centimeters in size to sand and powder in millimeters, the requirements for the conveyor's carrying surface, sealing, and stability vary considerably.

Process Complexity: The conveying of circulating loads (return material) requires precise metering and path distribution to optimize sand crusher efficiency.

Harsh Environment: Highly abrasive sand and aggregate materials cause rapid wear on belts and idlers; the production process generates a large amount of dust, placing high demands on equipment sealing and environmental protection.

| Belt width (mm) |

Conveying length (m)

Power (kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

| 500 |

≤ 12/3 |

≤ 12-20/4-5.5 |

≤ 20-30/5.5-7.5 |

1.3-1.6 |

40-100 |

| 650 |

≤ 12/4 |

≤ 12-20/5.5 |

≤ 20-30/7.5-11 |

1.3-1.6 |

80-120 |

| 800 |

≤ 10/4 |

≤ 10-15/5.5 |

≤ 15-30/7.5-15 |

1.3-1.6 |

120-200 |

| 1000 |

≤ 10/5.5 |

≤ 10-20/7.5-11 |

≤ 20-40/11-22 |

1.3-2.0 |

200-320 |

| 1200 |

≤ 10/7.5 |

≤ 10-20/11 |

≤ 20-40/15-30 |

1.3-2.0 |

300-500 |

Core Advantages: Conveying Solutions Optimized for Sand Production

Equipping mobile or stationary sand crushing plants with professional conveying systems brings comprehensive improvements.

Ensuring Continuous Production and Maximum Capacity

Sand crushers (such as vertical shaft impact crushers) require "full chamber feeding" to achieve optimal crushing effect and particle shape. A stable, adjustable conveying system perfectly matched to the host machine's capacity ensures that the sand making machine continuously receives the optimal feed rate, avoiding production fluctuations, poor particle shape, or equipment idling caused by uneven feeding, thus unleashing the full potential of the production line.

Precise Control of Finished Sand Quality

The gradation and fines content of the finished sand are key quality indicators. The conveying system precisely guides the screened coarse materials, fine materials, and stone powder to different finished product piles or return paths. Combined with processes such as wetting and powder separation, this achieves precise control over the quality of the final sand product. This directly relates to the market value and competitiveness of the product.

Significantly Reduced Operating and Maintenance Costs

To address the high abrasiveness of sand-making materials, the use of tear-resistant, wear-resistant special conveyor belts, long-life ceramic-coated or wear-resistant idlers significantly extends the replacement cycle of key components. The excellent fully enclosed dust-proof design not only meets environmental requirements but also reduces material loss and on-site cleaning costs, and protects bearings and other transmission components, reducing the failure rate.

Application Case: From Challenge to Excellence in Practice

In a large granite sand making project in southern China, we faced a severe challenge: the raw material had a high silicon content and was extremely abrasive, and the customer required a production capacity of 200 tons of high-quality manufactured sand per hour, with environmental compliance being mandatory. We designed a complete mobile sand making production line for them, with the conveying system being a key design focus:

Feeding to the cone crusher main belt: A thickened impact-resistant rubber layer belt was used, and multi-stage buffer beds and sealed guide chutes were added at the feeding point to withstand the impact of large falling materials.

Sand making machine circulating material belt: A short-distance return belt with an adjustable distribution valve was designed to facilitate quick adjustment of the circulating load rate according to working conditions, optimizing the efficiency of the sand making machine.

Finished sand output belt: A fully enclosed design was used throughout, and an atomizing spray device was installed at the discharge end to effectively control dust during loading.

The stable operation of this system helped the customer achieve an equipment utilization rate of over 95% under abrasive working conditions, the finished sand gradation fully met the standards, and uncontrolled dust emissions were effectively controlled, making it a regional environmental demonstration project.

Equipment Selection and Configuration Recommendations

When selecting conveyors for a sand making plant, it is essential to consider the system from a holistic engineering perspective. Systematic Design, Not Standalone Procurement: The conveying system must be designed in conjunction with the crushing and screening main equipment, calculating the flow rate, drop height, and connection angles at each node to avoid material flow bottlenecks.

Key Component Upgrade Options:

Belts: Prioritize wear-resistant, anti-longitudinal tearing steel cord or high-strength EP canvas belts, with a thickened top layer.

Idlers: High-density polyethylene idlers or ceramic-coated idlers can significantly extend wear life. Seals must use multiple labyrinth seals to prevent dust from entering the bearings.

Cleaners: Equip with multiple cleaners (alloy blade primary cleaning, polyurethane secondary cleaning, V-shaped return cleaning) to effectively remove adhering materials and protect the rollers and belts.

Intelligent and Environmentally Friendly Integration: Consider adding a belt scale for feed metering, and integrating automatic correction and interlocking emergency stop devices. For environmental protection, be sure to choose modular fully enclosed covers or dust suppression air ducts.

Frequently Asked Questions (FAQ)

Q1: Why are belt conveyors used for transporting finished sand particularly prone to misalignment and spillage?

There are two main reasons: First, sand has good fluidity, and uneven distribution across the belt cross-section easily leads to a shift in the center of gravity; second, fine sand can easily get stuck in the gaps between the idlers and brackets, causing the idlers to rotate poorly. Solutions include: using idler sets with deeper troughs and larger side roller angles to enhance centering ability; installing high-sensitivity automatic self-aligning idlers; and regularly cleaning and maintaining all idlers to ensure smooth rotation.

Q2: What should be considered for the return material (circulating load) conveying in a sand production plant?

Return material conveying is crucial for optimizing sand production efficiency. Considerations include: 1) Shortest path: Reduce transfer points to lower the risk of blockages and dust; 2) Adjustable feeding: Install a splitter gate or variable frequency speed control on the return belt to precisely control the amount of circulating material entering the sand making machine; 3) Wear resistance reinforcement: Return material is usually medium-sized sharp aggregate, which causes significant wear on the belt and chutes, requiring localized reinforcement.

Q3: How can conveyor belts prevent clogging when handling wet or clay-containing materials during sand production?

For sticky materials: 1) Use conveyor belts with a Teflon (PTFE) coating or a diamond pattern surface to reduce material adhesion; 2) Install vibrators or air cannons at the feeding point and cleaning points to assist in material removal; 3) Increase the configuration of non-contact (e.g., air bag type) cleaners to improve cleaning efficiency; 4) Design a larger chute angle and a smooth inner lining (such as UHMW polyethylene plates).

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!