1000 T/H Limestone Crushing Equipment Selection Guide and Solutions

In today's era of continuous growth in demand for large-scale infrastructure construction, cement production, and environmentally friendly aggregates, limestone, as a core raw material, has become a key indicator of a mining project's and even a region's industrial competitiveness due to its efficient and large-scale processing capabilities.

A 1000-ton-per-hour crushing production line is not only a symbol of production capacity but also an extreme test of equipment performance, process design, and comprehensive service capabilities. As a mining crushing equipment manufacturer with twenty years of professional experience, we deeply understand that behind every thousand-ton-level project lies the relentless pursuit of "high output, low energy consumption, long-term stability, and superior finished products."

I. The Challenge of a Thousand-Ton-Level Project: More Than Just "Large," It Lies in "Precision" and "Stability"

A 1000-ton-per-hour production line means handling nearly 20,000 tons of material daily. This presents multi-dimensional challenges for the crushing system:

1. Equipment Load-Bearing Capacity and Wear Resistance: Although limestone is a medium-hard material, such a massive continuous throughput places stringent requirements on the impact fatigue resistance and wear resistance of the equipment's core components.

2. Smooth Process Flow: From coarse crushing to medium and fine crushing, and then to screening and conveying, any bottleneck or malfunction in any link will lead to a complete production stoppage, resulting in huge losses.

3. Precise Control of Finished Product Particle Shape: Different application areas (such as high-quality aggregates, cement raw materials, and desulfurizers) have different requirements for finished product particle shape and gradation, requiring equipment with excellent shaping and adjustment capabilities.

4. Overall Operating Costs: With a huge production capacity, subtle differences in power consumption, wear parts consumption, and maintenance manpower will be amplified into significant differences in operating costs.

II. Core Equipment Selection: Building the Backbone of a Thousand-Ton Production Capacity

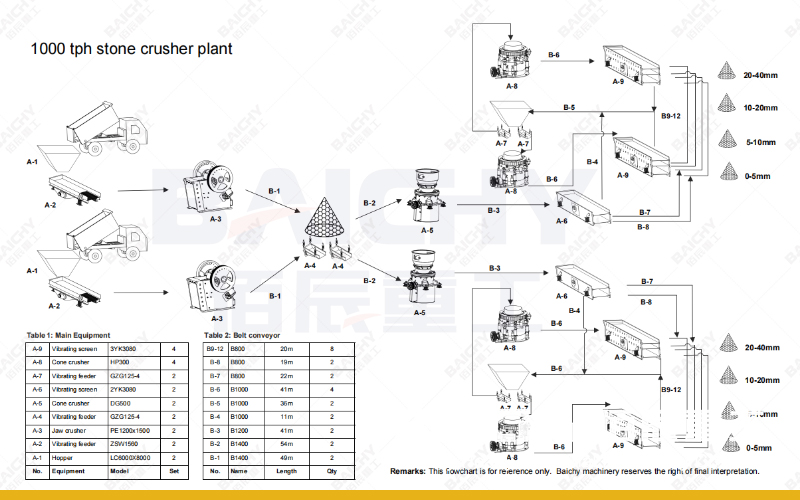

For limestone characteristics and thousand-ton-level production capacity requirements, a classic and efficient core equipment configuration is typically as follows. We adhere to the "scenario-based" principle, that is, optimizing the combination based on specific ore characteristics, product requirements, site layout, and investment budget.

Here is a typical high-performance, cost-effective configuration for reference:

Process Section | Recommended Core Equipment Model | Key Advantages | Suitable Scenarios

Primary Crushing (Coarse Crushing)

Heavy-duty Hammer Crusher / Jaw Crusher

1. Heavy-duty Hammer Crusher: High single-machine output, achieving one-stage forming (eliminating secondary crushing), convenient discharge particle size adjustment, especially suitable for medium-hardness limestone and below.

2. Large Jaw Crusher: Extremely robust structure, good wear resistance, more stable processing of raw materials with slightly higher mud content or strong abrasiveness, making it the reliable first choice for ultra-large production lines. Suitable for raw material particle size (≤1200mm), when pursuing simplified single-stage crushing or when the raw material is highly abrasive.

Secondary Crushing (Medium and Fine Crushing)

Multi-cylinder Hydraulic Cone Crusher / Impact Crusher

1. Multi-cylinder Cone Crusher: Layered crushing principle, high output, low power consumption, long service life of wearing parts, excellent finished product particle shape, particularly suitable for producing high-quality aggregates.

2. Large Impact Crusher: High crushing ratio, good product particle shape, flexible adjustment, suitable for applications with less stringent requirements on stone powder content or those requiring good particle shape. Suitable for applications with strict requirements on finished product particle shape and gradation; or for processing medium-sized raw materials after coarse crushing for fine shaping.

Screening and Conveying

Large Multi-Layer Heavy-Duty Vibrating Screen / High-Strength Belt Conveyor

1. Heavy-Duty Vibrating Screen: High screening efficiency, large throughput, robust and durable, ensuring accurate grading and providing a guarantee for closed-loop circulation.

2. High-Strength Conveyor: Long distance, large inclination angle, and high belt speed design ensure continuous and smooth material flow; it is the "blood vessels" of the production line. The reliability of all links requiring material grading and transfer directly determines the continuous operation rate of the entire line.

(Table Note: This is a recommendation under standard operating conditions; actual selection requires detailed calculation and simulation based on specific parameters.)

III. Beyond Equipment: Twenty Years of Global Scenario-Based Service Capabilities

We deeply understand that delivering a piece of equipment is only the beginning of cooperation. As a company serving global mines, our value lies in:

• Pre-design of processes: Our engineering team can intervene early in the project, conducting simulations and layout designs based on your ore report and product goals, optimizing investment from the outset.

• Self-developed and self-produced core components: We use proprietary materials and processes for core wear-resistant parts such as crusher rotors, hammers, and grinding mill walls, ensuring ultra-long service life even under impacts of thousands of tons, reducing your per-ton cost.

• Intelligent operation and maintenance support: We provide remote equipment monitoring and early warning systems to detect potential faults in advance, transforming "reactive maintenance" into "planned maintenance," maximizing your uptime.

• Global rapid response network: We have service centers and spare parts warehouses in multiple key mining regions worldwide, ensuring timely technical and logistical support wherever your project is located.

Investing in a 1000-ton-per-hour limestone crushing production line is a significant strategic decision. It requires more than just a few large machines; it requires a partner who deeply understands your goals, is proficient in the process, and can provide full lifecycle support. With two decades of deep technological expertise and global project experience, we are committed to transforming every ambitious "thousand-ton-level" blueprint into a highly efficient, profitable, and sustainable reality. We don't offer standard product catalogs, but rather tailor-made, scenario-based solutions.

Contact us today and let our professional team provide end-to-end value enhancement for your next benchmark project, from feasibility analysis to stable production.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.