The design features of the jaw crusher are mainly reflected in the following aspects:

1. Manufacturing process:

The jaw crusher combines domestic and foreign technology and many years of manufacturing experience from manufacturers, is made of high-quality materials, and uses finite element analysis technology to make the equipment have higher working intensity and help improve production efficiency. promote.

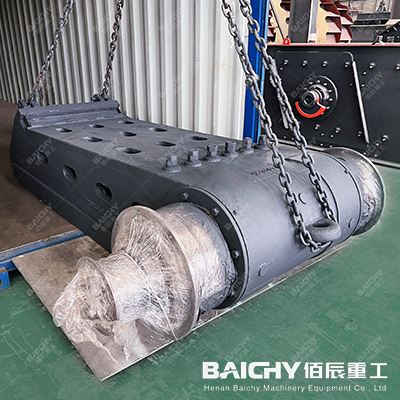

2. Frame design

The frame is an important part of the jaw crusher. There are two types: welded type and assembled type. The welded type adopts the welding method of large arc transition fillet and low stress zone, which reduces stress concentration and ensures equal strength of the frame in all directions. It has the characteristics of impact resistance, uniform stress and low failure rate. The assembled type adopts a good modular weldless frame structure design, which has high fatigue strength and high reliability.

3. Cavity design:

The jaw crusher has a symmetrical V-shaped cavity design, a large toggle plate inclination angle, a large stroke and a reasonable rotational speed. These designs make the feed granularity larger, the output higher, the granularity more uniform, and the particle size reduced. The jaws are worn.

4. Movable jaw assembly:

The movable jaw assembly uses a forged eccentric shaft, excellent heavy-duty rolling bearings and a movable jaw optimized by finite element software to ensure the high impact resistance and stability of the movable jaw assembly. At the same time, the labyrinth seal and centralized lubrication system ensure that the bearing grease is not contaminated, making lubrication more convenient and running longer and more stably.

5. Bearing design:

The overall cast steel bearing seat structure ensures full cooperation with the frame, avoids unnecessary radial load on the bearing during the tightening process of the combined bearing seat, and makes the bearing run more smoothly. The bearing seat of the jaw crusher has higher load-bearing capacity and effective sealed bearings, which greatly extends its life.

6. Particle size adjustment:

The jaw crusher has a convenient and fast particle size adjustment function. By adjusting the swing trajectory and angle of the swing jaw plate, the crushing requirements for different particle sizes of materials can be achieved.

7. Development trend:

With the enlargement of equipment specifications, new mechanisms must be used for the adjustment device and safety device of the jaw crusher. At present, it has become a trend to use a hydraulic adjustment mechanism for the size of the ore discharge port. This adjustment method is not only simple and fast, but also can be adjusted in real time as needed.

In general, the design characteristics of the jaw crusher are reflected in its manufacturing process, frame design, cavity design, movable jaw components, bearing design, particle size adjustment and development trends. These characteristics make the jaw crusher perform well in crushing ores and rocks of various hardnesses, and are widely used in mining, metallurgy, construction, chemical industry and other fields.