Are you facing this dilemma when starting a small to medium-sized sand and gravel plant or undertaking an engineering project: low output requirements, limited equipment budget, and concerns about frequent breakdowns of inexpensive equipment leading to increased maintenance costs and downtime losses?

We understand your concerns. Choosing your first crusher isn't about finding the cheapest, but the most cost-effective that is, obtaining the most reliable stability and production efficiency within a reasonable price. This article will focus on analyzing what constitutes a truly affordable crusher.

I. True Affordability Means Long-Term Stable Low Operating Costs

Many users blindly pursue low prices, neglecting the lifetime cost of equipment. A truly affordable crusher should possess the following characteristics:

• Reasonable Purchase Cost: Initial investment fits within the project budget.

• Low Failure Rate: Core components such as bearings and jaw plates are made of wear-resistant materials, with a robust and durable structure.

• Easy Maintenance: User-friendly design, simple and quick routine maintenance and replacement of wear parts, saving labor and time costs.

Our durable jaw crushers are designed based on this concept. The machine body is made of high-quality steel, and the moving jaw assembly is precisely calculated to ensure crushing force while maintaining smooth operation, reducing the probability of failure from the outset and achieving long-term cost savings for you.

II. Recommended Main Model: Why is a Jaw Crusher the First Choice for Small and Medium-Sized Users?

For small and medium-sized production users, jaw crushers are often the optimal choice for entry-level and cost-effective operation.

• Simple Structure, Robust and Durable: Its working principle determines its inherent reliability, enabling it to handle various types of rock with high hardness.

• Extremely Low Maintenance Costs: The core crushing structure is not complex, and replacement of wear parts (such as jaw plates) is convenient and the price is transparent.

• High Adaptability: Various feed opening sizes can meet the initial crushing needs of different sizes of stone.

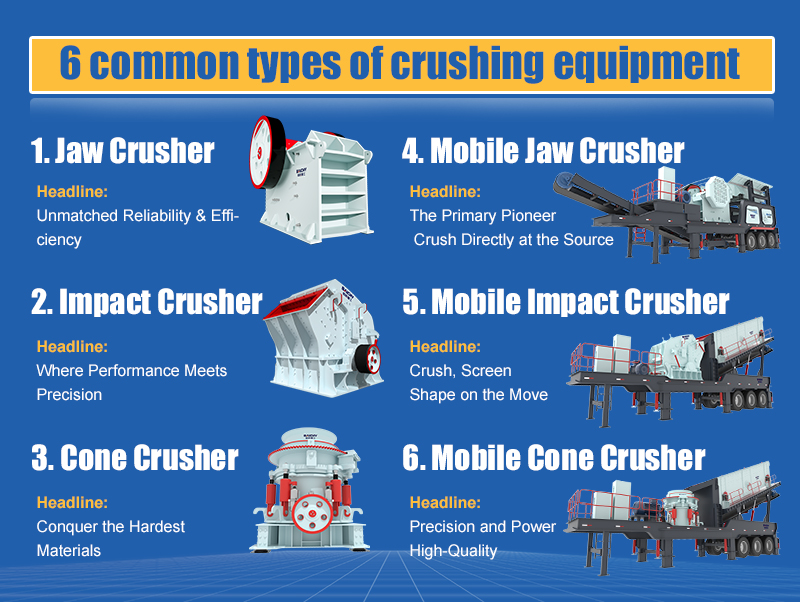

(Image suggestion: A working scene diagram of a small jaw crusher, clearly marked with the sturdy frame and easily replaceable jaw plates.)

III. Factory Direct Supply: Eliminating Intermediaries Leads to True Value

As a direct sales manufacturer of crushers, we eliminate the markups of various distributors, passing the profits directly to end users. This means:

• More Competitive Pricing: You can obtain equipment of equivalent quality at a lower cost.

• More Direct and Efficient Service: From consultation and selection to installation, commissioning, and after-sales maintenance, our factory's technical team provides one-on-one service, ensuring faster response and more thorough problem-solving.

• Customized Solutions: We can provide the most suitable small crusher pricing plan based on your specific materials, expected output, and site conditions, avoiding the need for you to pay for unnecessary features.

IV. Our Commitment: Ensuring Every Penny of Your Investment is Worth It

We offer more than just equipment; we provide a comprehensive solution to help you profit. From equipment selection guidance to installation technical support, we accompany you throughout the entire process, ensuring your production line starts up smoothly and you quickly recoup your costs.