As a mining crushing equipment manufacturer with 20 years of professional experience, we have witnessed the rapid development of China's mining machinery industry. Among numerous equipment models, the 600x900 jaw crusher (commonly known as PE-600×900 in the industry) is undoubtedly a landmark product. With its exceptional reliability, wide applicability, and high cost-effectiveness, it has become the absolute workhorse for coarse crushing of medium-hard materials, and is hailed by customers as the heart of mining production lines.

This article will provide a comprehensive analysis of this classic equipment, drawing on our twenty years of technical expertise and market feedback.

| Key Words | PE-600×900 Jaw Crusher Manufacturer Details |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Understanding the Meaning Behind 600x900

600x900 is not simply a combination of numbers; it precisely defines the core structural dimensions of this jaw crusher.

600mm: Represents the feed opening width. This means the equipment can handle a maximum feed size of approximately 500mm, easily processing medium-sized ores and rocks.

900mm: Represents the feed opening length. The larger length ensures higher feeding capacity and throughput efficiency.

This model of jaw crusher perfectly balances processing capacity, equipment investment, and operating costs, making it particularly suitable for small and medium-sized aggregate production lines with a capacity of 50-180 tons per hour, and primary crushing in mining operations.

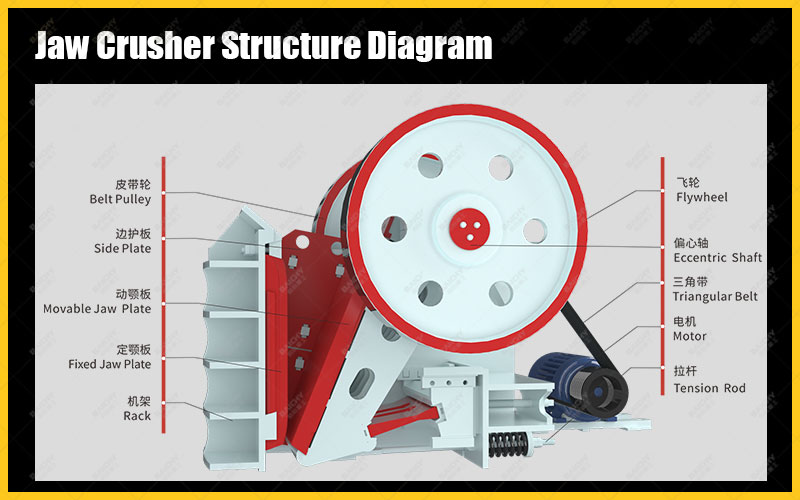

PE jaw crusher structure diagram

II. Equipment Overview: Robust and Durable Structural Design

The PE-600×900 jaw crusher adopts the classic toggle plate mechanical design principle, resulting in a simple, robust, and durable structure.

Frame: Made of high-quality steel plate and stress-relieved, it possesses extremely high mechanical strength and stability.

Movable and Fixed Jaws: The jaw plates and jaw beds are made of high-manganese steel, offering strong wear resistance and a long service life.

Eccentric Shaft: Processed from large forged blanks, its load-bearing capacity far exceeds that of similar models, guaranteeing the high reliability of the equipment. Adjustment Device: Adopts a wedge-type discharge opening adjustment mechanism, offering a large adjustment range (usually between 65-160mm), allowing for flexible control of the output particle size.

III. Core Advantages: The Crystallization of 20 Years of Technological Refinement

After twenty years of continuous optimization, our 600×900 jaw crusher now possesses multiple significant advantages:

1. Exceptional Reliability and Long Lifespan: Core components such as bearings, jaw plates, and eccentric shafts use internationally renowned brands or are customized to the highest standards, resulting in equipment uptime far exceeding the industry average.

2. Outstanding Crushing Efficiency: The optimized cavity design allows for more effective compression and crushing of materials within the crushing chamber, resulting in uniform product particle size, fewer flaky particles, and a high cubic content.

3. Lower Operating and Maintenance Costs: Simple structure with fewer daily maintenance points; easily replaceable wear parts (such as jaw plates) with strong universality, minimizing user downtime and spare parts costs.

4. Wide Material Adaptability: Suitable not only for hard materials such as granite, basalt, and river pebbles, but also performs excellently with medium-hard materials such as limestone and shale.

5. Energy Saving and Environmental Protection: The new motor drive and transmission design saves approximately 15-20% energy compared to older equipment. At the same time, the equipment has good sealing performance and can be effectively equipped with dust removal points to meet environmental protection requirements.

Stationary crushing production line

IV. Application Cases: The Common Choice of Global Customers

Case 1 (Domestic): A large-scale sand and gravel aggregate project in Hubei Province used one of our PE-600×900 jaw crushers as the primary crusher, paired with a cone crusher and sand making machine. The output is stable at 160 tons per hour, and the equipment has been running continuously and stably for over 5 years. The customer highly praises its robust and durable, and excellent output particle shape characteristics.

Case 2 (Overseas): A primary crushing station for an iron ore mine in Southeast Asia faced harsh working conditions. Our equipment, with its powerful iron protection function (toggle plate design) and impact resistance, successfully handled multiple unexpected situations, ensuring the continuous operation of the entire production line and demonstrating the excellent quality of Made in China. V. Recommended Related Equipment (Complete Production Line Solutions)

A single jaw crusher cannot constitute a complete production line. We usually recommend the following supporting solutions:

1. Classic Sand and Gravel Production Line: PE-600×900 Jaw Crusher → Single-cylinder hydraulic cone crusher (medium crushing) → Multi-cylinder hydraulic cone crusher/impact crusher (fine crushing and sand making) → Circular vibrating screen.

2. Mobile Crushing Solution: If the project site is scattered, we recommend using an integrated mobile jaw crushing station with a feeder and a PE-600×900 jaw crusher, allowing for flexible relocation and rapid commissioning.

VI. Frequently Asked Questions (FAQ)

Q1: What are the maximum feed and discharge particle sizes of this equipment?

A1: The maximum feed particle size is approximately 500mm, and the discharge opening adjustment range is 65-160mm, with a corresponding adjustable discharge particle size of approximately 100-200mm.

Q2: What is its specific processing capacity (output)?

A2: The processing capacity is affected by factors such as material hardness, humidity, and feed particle size. For ordinary granite, the hourly output range is usually between 50-180 tons.

Q3: What are the main wear parts of the equipment? What is the replacement cycle?

A3: The main wear parts are the fixed jaw plate and the movable jaw plate. The replacement cycle depends entirely on the hardness of the crushed material, ranging from several hundred hours to thousands of hours. We offer jaw plates made of various materials (such as standard manganese steel, reinforced manganese steel, etc.) for customers to choose from.

Q4: Can you provide installation guidance and technical support?

A4: Absolutely. As a manufacturer with 20 years of experience, we provide a full range of services, from basic drawings and process layout to on-site installation guidance by engineers. We also provide lifelong technical consulting and original spare parts supply.

Q5: What are your advantages compared to other brands of equipment with the same specifications?

A5: Our core advantage lies in the detailed optimization and reliability control brought about by 20 years of professional manufacturing experience. From steel selection and heat treatment processes to assembly precision, we have an internal control system that is stricter than industry standards, ensuring the exceptional stability of our equipment under long-term heavy-duty operation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.