800 tphLimestone Production Line Solution

I. Large-scale, Multi-specification Production Lines Have Become the Market Mainstream

With the continuous development of infrastructure construction and the high-quality building materials market, the demands of mine owners for production lines have long surpassed the initial stage of simply being able to crush. Currently, the market is demanding comprehensive solutions like the one you've planned – high-capacity, multi-specification production lines that maximize product value. A production line capable of simultaneously and stably producing multiple specifications of aggregates and high-quality manufactured sand is a key weapon for enhancing competitiveness and securing high-profit margins.

Stone Crushing Plant PDF,Download ↓↓↓

II. The Technical Core Behind Customer Needs

The 800-ton/hour Multi-product Production Line: More Than Just a Collection of Equipment

Your described jaw crusher + secondary crushing + VSI + multi-layer screen + auxiliary system is a classic and efficient configuration, but its essence lies in the systematic process design. Achieving the goal of simultaneous production of four finished products presents extreme challenges to process design, material balance, and equipment coordination.

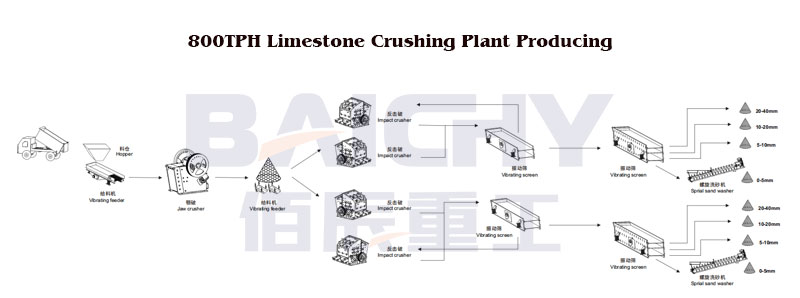

800TPH Limestone Crushing Plant Producing

Three Core Technical Challenges

1. Precise Material Balance and Closed-loop Control: How to rationally distribute 800 tons of raw materials to four finished products and handle the return material cycle is fundamental to achieving stable and efficient operation. This requires precise calculations and simulations.

2. Efficient and Intelligent Screening System: This is the decision-making center of the production line. The selection, screen mesh configuration, and layout of the multi-layer vibrating screen directly determine the grading accuracy and capacity achievement rate of the four products.

3. Preparation and Purification of High-quality Sand (especially white sand): Producing white sand from light-colored limestone means extremely high requirements for finished product purity and powder content. Simple crushing and screening are far from sufficient; efficient washing, dewatering, and fine sand recovery modules must be integrated to remove impurities and control the fineness modulus.

III. Our Advantages: Twenty Years of Experience, Delivering Turnkey Projects

Facing such a complex project, we are not just an equipment supplier, but also a full-process turnkey partner, providing services from mine analysis to finished product delivery.

• Experience-driven Process Design: With a 20-year database and hundreds of cases, our engineers can perform 3D process simulations and material balance calculations for you, optimizing the layout from the source to ensure capacity and yield.

• Customized Equipment Combination: We offer a full range of proprietary core equipment (such as high-performance jaw crushers, multi-cylinder hydraulic cone crushers/impact crushers, high-efficiency VSI sand making machines, and large vibrating screens), and can fine-tune parameters based on your limestone characteristics (such as clay content and hardness) to ensure perfect matching between equipment.

• Intelligent Control System: Integrated with an advanced PLC central control system, it monitors production capacity, load, and finished product ratio in real time, and allows for remote diagnosis and parameter adjustment, making complex production simple and controllable.

• White Sand Solution Expert: We provide a one-stop solution for high-quality sand production, from VSI shaping and air separation to wheel/spiral sand washing and fine sand recovery, ensuring stable quality of your high-value-added products.

800TPH Limestone Crushing Plant Producing 4 Final Products Including White Sand

IV. Success Stories: Theory Put into Practice

We previously built a production line for a large building materials group in East China that processed light-colored limestone, with core requirements highly similar to yours:

• Raw materials: Light-colored limestone

• Production capacity: Designed output of 850 tons per hour, actual stable operation ≥ 800 tons per hour

• Finished products: 0-5mm high-quality sand (partially washed), 5-10mm, 10-20mm, 20-31.5mm aggregates

800TPH Limestone Crushing Plant Producing

• Solution: A process combination of heavy-duty jaw crusher + single-cylinder hydraulic cone crusher (medium crushing) + multi-cylinder hydraulic cone crusher (fine crushing) + VSI shaping sand making machine + four three-layer vibrating screens + double-wheel sand washing and recycling machine was adopted. Through a clever circuit design, the proportion of the four finished products could be flexibly adjusted online. The whiteness and gradation of the washed sand met the requirements of high-end dry-mix mortar, bringing the customer excess profits.

V. Recommended Core Equipment

For your project, we recommend the following core modules:

1. Coarse Crushing Module: JC series European version jaw crusher, with an extra-large feed opening and robust structure, laying a solid foundation for 800 tons of production capacity.

2. Medium and Fine Crushing Module: HPC multi-cylinder hydraulic cone crusher, using the lamination crushing principle, producing more cubic aggregates, with low wear costs, suitable for continuous high-intensity operation of limestone.

3. Sand Making and Shaping Module: The VSI series vertical shaft impact crusher, with optional stone-on-stone or stone-on-iron configurations, is optimized for producing high-quality manufactured sand with excellent gradation and rounded particle shape.

4. Screening and Washing Module: A combination of multi-layer heavy-duty circular vibrating screens equipped with wear-resistant and anti-clogging screens; and XS series wheel-type sand washing machines and fine sand recovery and dewatering integrated machines, ensuring the quality and recovery rate of white sand.

VI. Frequently Asked Questions (FAQ)

Q1: How is the actual production line capacity guaranteed to stably reach 800 tons/hour?

A: We ensure this through the equipment selection margin method and system bottleneck analysis method. The theoretical capacity of key main machines is selected with a coefficient of 1.2-1.3 times, and the conveying and screening capabilities of the entire system are designed with redundancy to avoid local bottlenecks affecting the overall performance.

Q2: Is the process very complex and difficult to operate when producing four products simultaneously?

A: On the contrary. The complex process logic has been integrated into our intelligent control system. The operator only needs to set the target product ratio on the touch screen, and the system will automatically adjust the relevant equipment parameters (such as feeder frequency, crusher discharge opening, etc.) to achieve one-button intelligent production.

Q3: How are water consumption and sludge treatment handled in the sand washing system for producing white sand?

A: We recommend equipping with a fine sand recovery machine and a filter press (optional). The fine sand recovery machine can recover more than 90% of the lost fine sand, significantly reducing waste; the sand washing wastewater can be recycled after sedimentation, and combined with a filter press for sludge treatment, achieving zero wastewater discharge and fully meeting environmental protection requirements.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!